Chapter 12: Tolerancing

advertisement

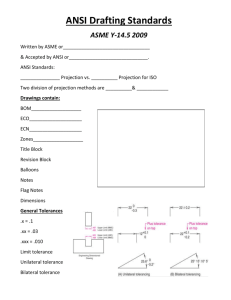

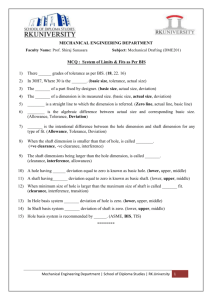

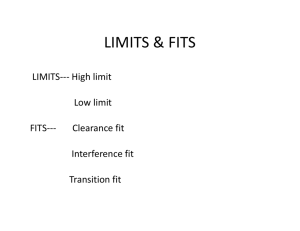

Chapter 12 Tolerancing 1. What is the purpose of Tolerancing? 2. When does the maximum clearance occur? 3. When does the minimum clearance occur? 4. Define “Nominal Size”. 5. What is the “Basic Hole System”? 6. What is the “Basic Shaft System”? 7. Why is the basic-hole system more common than the basic-shaft system? 8. Which method is the preferred method of expressing tolerances? 9. What do the two numbers of a limit dimension mean? 10. List five classes of fit. 11. What does the tem “Hole-Basis system of preferred fits” mean in reference to the metric system of tolerances and fits? 12. What does the tem “Shaft-Basis system of preferred fits” mean in reference to the metric system of tolerances and fits? 13. How is the tolerance grade specified in the metric system of tolerances and fits? Tolerance Chart Assignment…Determine the limit dimensions for the hole and shaft for each of the basic sizes identified. The values for .375, RC5 have been provided as an example. Basic Size 0.375 0.750 1.875 Name: RC 5 Hole Shaft .3759 .3740 .3750 .3734 LC 1 Hole LT4 Shaft Hole FN1 Shaft Hole Shaft