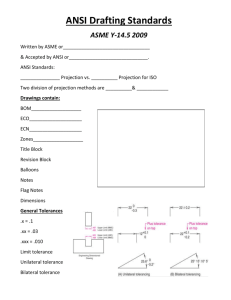

GD&T F2016 • Dimension: is the numerical value that defines the size or geometric characteristic of a feature. • Basic dimension: is the numerical value defining the theoretically exact size of a feature. • Reference dimension: is the numerical value enclosed in parentheses provided for information only and is not used in the fabrication of the part • Actual size :the measured size of the finished part after machining • Dimension line :is the thin solid line which shows the extent and direction of a dimension. • Arrows :are placed at the ends of dimension lines to show the limits of the dimension. • Extension line : • is the thin solid line perpendicular to a dimension line indicating which feature is associated with the dimension. • Leader line :is the thin solid line used to indicate the feature with which a dimension, note, or symbol is associated. • Tolerance :is the amount a particular dimension is allowed to vary. • Plus and minus dimensioning :is the allowable positive and negative variance from the dimension specified. • Limits of size is the largest acceptable size and the minimum acceptable size of a feature. The largest acceptable size is expressed as the maximum material condition (MMC), The smallest acceptable size is expressed as the least material condition (LMC). • MMC: The condition where a size feature contains the maximum amount of material within the stated limits of size. I.e., largest shaft and smallest hole. • LMC: The condition where a size feature contains the least amount of material within the stated limits of size. I.e., smallest shaft and largest hole. Limit tolerancing • Bilateral tolerances :specify the acceptable measurements in two opposite directions from a specified dimension. • Unilateral tolerances :define the acceptable range of measurements in only one direction from a given dimension. • Limit dimensions: give the acceptable measurements within two absolute dimensions. Diameter symbol is the symbol which is placed preceding a numerical value indicating that the associated dimension shows the diameter of a circle. The symbol used is the Greek letter phi. Radius symbol is the symbol which is placed preceding a numerical value indicating that the associated dimension shows the radius of a circle. The radius symbol used is the capital letter R. Datum is the theoretically exact point used as a reference for tabular dimensioning. Tabular Dimensions - When a company manufactures a family of parts or assemblies that are exactly alike in shape except for dimensions , tabular dimensioning is used on a drawing. Letters and numbers in a tabular from are used instead of dimensions to denote size. Coordinate Dimensions - Coordinate dimensioning is used on prints that would require many dimension and extension lines. Coordinate dimensioning helps to keep the drawing from becoming difficult to read. This type of dimensioning is frequently used on prints of parts to be machined by numerical control. Standard practices • Dimensions should be grouped for uniform appearance as shown. Dimensions are to be kept outside of the boundaries of views of objects wherever practical. Where there are several parallel dimensions, the values should be staggered. Figure Also The symbol X is used to indicate the number of times a feature is to be repeated. U.S System: ASME standards for the U.S dimensioning use the decimal inch values. When the decimal inch sys-tem is used, a zero is not used to the left of the decimal point for values less than one inch. The same number of decimal places should be used for dimensions and tolerancing. Metric Dimensioning: ASME standards for the use of metric dimensioning require all the dimensions to be expressed in milli-meters (mm). The (mm) is not needed on each dimension, but it is used when a dimension is used in a notation. Zeros precedes decimal point when the value is less than one millimeters. GD&T Symbols Fit types • Clearance fit occurs when two toleranced mating parts will always leave a space or clearance when assembled. • Interference fit occurs when two toleranced mating parts will always interfere when assembled or forced together . • Transition fit occurs when two toleranced mating parts will sometimes be an interference fit and sometimes be a clearance fit when assembled • Line fit :results in surface contact or clearance when limits are reached Cylindrical Fits:ANSI B4.1 • • • • • • Standard Precision Fit; English Units Running and Sliding (RC): RC1 to RC9 Clearance Locational (LC): LC1 to LC11 Transition Locational (LT): LT1 to LT6 Interference Locational (LN): LN1 to LN3 Force and Shrinks (FN): FN1 to FN5 Example of RC 9 Hole and shaft have a basic size of 2.5” Example Of LN2 : Hole and shaft have a basic diameter of 2.5” ANSI cylindrical FEATURE CONTROL FRAME GEOMETRIC SYMBOL TOLERANCE INFORMATION DATUM REFERENCES COMPARTMENT VARIABLES THE RELATIVE TO OF THE FEATURE MUST BE WITHIN CONNECTING WORDS Example Example Example Positioning tolerance (Appendix for Bonus tol) Reference : • ASME GD&T • ASME Y14.5 and ISO 1101 are the written standards • http://www.aidt.edu/ Appandix Bonus Tolerance • Here is the beauty of the system! The specified tolerance was: This means that the tolerance is .010 if the hole size is the MMC size, or .497. If the hole is bigger, we get a bonus tolerance equal to the difference between the MMC size and the actual size. Ex of Tolerance of a shaft and a hole • Tolerance is the variation of a size with regards to it’s actual nominal value . • CNC machine tolerance range: 0.00004” to 0.004” • Lathe machine tolerance range: 0.01” to 0.001”