OPSM 451 Service Operations Management

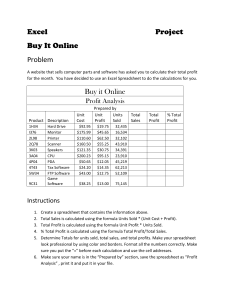

advertisement

Koç University OPSM 301 Operations Management Class 10: Introduction to Linear Programming Zeynep Aksin zaksin@ku.edu.tr Announcements Assignment 2 due on Monday Midterm 1 next Wednesday On Monday October 31, OPSM 301 class will be held in the computer lab SOS 180 – Graded class participation activity – Will show how to use Excel Solver to solve linear programs – You will need this for assignment 3 A Kristen’s like example R1 R2 2 min/unit 10 min/unit •Flow time T = 2+10+6 = 18 min. •System cycle time 1/R= 10 min. •Throughput rate R= 6 units / hour •Utilizations: R1: 2/10=20% R2=100% (bottleneck) R3=6/10=60% R3 6 min/unit Tools: Gantt Chart Gantt charts show the time at which different activities are performed, as well as the sequence of activities Resources 1 activities 2 3 4 time Three Workers R2 R1 2 min/unit 10 min/unit W2 W1 R3 R2 R1 1 1 R3 6 min/unit 2 2 W3 3 3 4 4 5 5 1 2 3 4 5 10 20 30 40 50 60 Three Workers Throughput time for a rush order of 1 unit R3 R2 System cycle time 1 1 2 2 3 3 4 4 5 5 Throughput time for an order of 5 units R1 1 2 3 4 5 10 20 30 40 50 60 Two Workers W2 W1 R3 R2 R1 1 1 2 2 3 3 4 4 5 5 1 2 3 4 5 10 20 30 40 50 60 Continue Kristen’s Cookie story.. The business matures Demand information is available You and your roommate decide to focus on chocolate chip or oatmeal raisin cookies Product Mix Decisions: Kristen Cookies offers 2 products Sale Price of Chocolate Chip Cookies: Cost of Materials: $5.00/dozen $2.50/dozen Sale Price of Oatmeal Raisin Cookies: Cost of Materials: $5.50/dozen $2.40/dozen Maximum weekly demand of Chocolate Chip Cookies: Maximum weekly demand of Oatmeal Raisin Cookies: Total weekly operating expense 100 dozen 50 dozen $270 Product Mix Decisions Total time available in week: 20 hrs Processing Times Mix & Dish Chocolate Chip 8 mins. (6+2/tray) 1 9 Oatmeal Raisin 5 mins. (3+2/tray) 1 14 Resource You RM+Oven Oven Load Oven Bake Cool & Set Pack Receive Total 5 2/tray 1 26 2 2/tray 1 25 RM RM Product Mix Decisions Margin per dozen Chocolate Chip cookies = $2.50 Margin per dozen Oatmeal Raisin cookies = $3.10 Margin per oven minute from Chocolate Chip cookies = $2.50 / 10 = $ 0.250 Margin per oven minute from Oatmeal Raisin cookies = $3.10 / 15 = $ 0.207 Baking only one type If I bake only chocolate chip: – In 20 hours I can bake 120 dozen – At a margin of 2.50 I will make 120*2.5=300 – But my demand is only 100 dozen! If I bake only oatmeal raisin: – In 20 hours I can bake 80 dozen – At a margin of 3.10 I will make 80*3.10=248 – But my demand is only 50 dozen! What about a mix of chocolate chip and oatmeal raisin? What is the best product mix? Linear programming Announcement Linear programming: Appendix A from another book-copy in course pack Skip graphical solution, skip sensitivity analysis for now You can use examples done in class, example A1, solved problem 1, Problem 3 as a study set (and all other problems if you like) Introduction We all face decision about how to use limited resources such as: – time – money – workers/manpower Mathematical Programming... find the optimal, or most efficient, way of using limited resources to achieve objectives. Optimization Example Applications OPSM: Product mix problem-how much of each product should be produced given resource constraints to maximize profits Finance: Construct a portfolio of securities that maximizes return while keeping "risk" below a predetermined level Marketing: Develop an advertising strategy to maximize exposure of potential customers while staying within a predetermined budget Components of Linear Programming A specified objective or a single goal, such as the maximization of profit, minimization of machine idle time etc. Decision variables represent choices available to the decision maker in terms of amounts of either inputs or outputs Constraints are limitations which restrict the alternatives available to decision makers Conditions for Applicability of Linear Programming Resources must be limited There must be an objective function There must be linearity in the constraints and in the objective function Resources and products must be homogeneous Decision variables must be divisible and nonnegative Components of Linear Programming There are three types of constraints: – (=<) An upper limit on the amount of some scarce resource – (>=) A lower bound that must be achieved in the final solution – (=) An exact specification of what a decision variable should be equal to in the final solution Parameters are fixed and given values which determine the relationships between the decision variables of the problem LP for Optimal Product Mix Selection xcc: xor: Dozens of chocolate chip cookies sold. Dozens of oatmeal raisin cookies sold. Max 2.5 xcc + 3.1 xor subject to 8 xcc + 5 xor < 10 xcc + 15 xor < 4 xcc + 4 xor < xcc < xor < 1200 1200 1200 Technology Constraints 100 50 Market Constraints Solving the LP using Excel Solver Optimal product-mix Number to make 100 13.33333 Unit Profits 2.5 3.1 Constraints You Total profit 291.3333333 Value RHS (constraint) 8 5 866.6667 1200 10 15 1200 1200 Room Mate 4 4 453.3333 1200 Market cc 1 0 100 100 Market or 0 1 13.33333 50 Oven Optimal Profit Constraint not binding in optimal solution Reading the variable information The optimal solution for Kristen’s is to produce, 100 dozen chocolate chip and 13.33 dozen oatmeal raisin resulting in an optimal profit of $291.33. (This is the maximum possible profit attainable with the current resources) Follow me using the file on the network drive Go to STORAGE E:\COURSES\UGRADS\OPSM301\SHARE Copy KristensLPexample.xls to your desktop Open the spreadsheet and click on first worksheet How Solver Views the Model Target cell - the cell in the spreadsheet that represents the objective function Changing cells - the cells in the spreadsheet representing the decision variables Constraint cells - the cells in the spreadsheet representing the LHS formulas on the constraints Goals For Spreadsheet Design Communication - A spreadsheet's primary business purpose is that of communicating information to managers. Reliability - The output a spreadsheet generates should be correct and consistent. Auditability - A manager should be able to retrace the steps followed to generate the different outputs from the model in order to understand the model and verify results. Modifiability - A well-designed spreadsheet should be easy to change or enhance in order to meet dynamic user requirements. Lets consider a slightly different version Unit profits from Aqua-Spas is $325 Available hours of labor is 1500 Make the appropriate changes in your spreadsheet and resolve. An Example LP Problem Blue Ridge Hot Tubs produces two types of hot tubs: Aqua-Spas & Hydro-Luxes. Find profit maximizing product-mix. Aqua-Spa Hydro-Lux Pumps 1 1 Labor 9 hours 6 hours Tubing 12 feet 16 feet Unit Profit $350 $300 There are 200 pumps, 1566 hours of labor, and 2880 feet of tubing available. 5 Steps In Formulating LP Models: 1. Understand the problem 2. Identify the decision variables: X1=number of Aqua-Spas to produce X2=number of Hydro-Luxes to produce 3. State the objective function as a linear combination of the decision variables: MAX: Profit = 350X1 + 300X2 5 Steps In Formulating LP Models (continued) 4. State the constraints as linear combinations of the decision variables. 1X1 + 1X2 <= 200 } pumps 9X1 + 6X2 <= 1566 } labor 12X1 + 16X2 <= 2880 } tubing 5. Identify any upper or lower bounds on the decision variables. X1 >= 0 X2 >= 0 Summary of the LP Model for Blue Ridge Hot Tubs MAX: 350X1 + 300X2 S.T.: 1X1 + 1X2 <= 200 9X1 + 6X2 <= 1566 12X1 + 16X2 <= 2880 X1 >= 0 X2 >= 0 Solving LP Problems: An Intuitive Approach Idea: Each Aqua-Spa (X1) generates the highest unit profit ($350), so let’s make as many of them as possible! How many would that be? – Let X2 = 0 • 1st constraint: • 2nd constraint: • 3rd constraint: 1X1 <= 200 9X1 <=1566 or X1 <=174 12X1 <= 2880 or X1 <= 240 If X2=0, the maximum value of X1 is 174 and the total profit is $350*174 + $300*0 = $60,900 This solution is feasible, but is it optimal? No! The Steps in Implementing an LP Model in a Spreadsheet 1. Organize the data for the model on the spreadsheet. 2. Reserve separate cells in the spreadsheet to represent each decision variable in the model. 3. Create a formula in a cell in the spreadsheet that corresponds to the objective function. 4. For each constraint, create a formula in a separate cell in the spreadsheet that corresponds to the left-hand side (LHS) of the constraint. Let’s Implement a Model for the Blue Ridge Hot Tubs Example... MAX: 350X1 + 300X2 S.T.: 1X1 + 1X2 <= 200 9X1 + 6X2 <= 1566 12X1 + 16X2 <= 2880 X1, X2 >= 0 } profit } pumps } labor } tubing } nonnegativity Preparing Excel You need the Solver add-in First check whether you have this add-in – Click on the DATA tab – Check if you have Solver under Analysis (far right) If not – Click on the Office Button (far left top) – Click on Excel Options (bottom of dialogue box) – Select Add-Ins from menu on the left – Add Solver add-in from the right menu In-class exercise Prepare a spreadsheet for the Blue Ridge Hot Tubs product mix problem we just formulated Solve the LP using solver Save the file with your name_lastname in E:\COURSES\UGRADS\OPSM301\HOMEWORK Consider the following changes – Unit profits from Aqua-Spas is $325 – Available hours of labor is 1500 – Make the appropriate changes in your spreadsheet and resolve. Implementing the Model