andrew hubbert - CES Engineering Jobs

advertisement

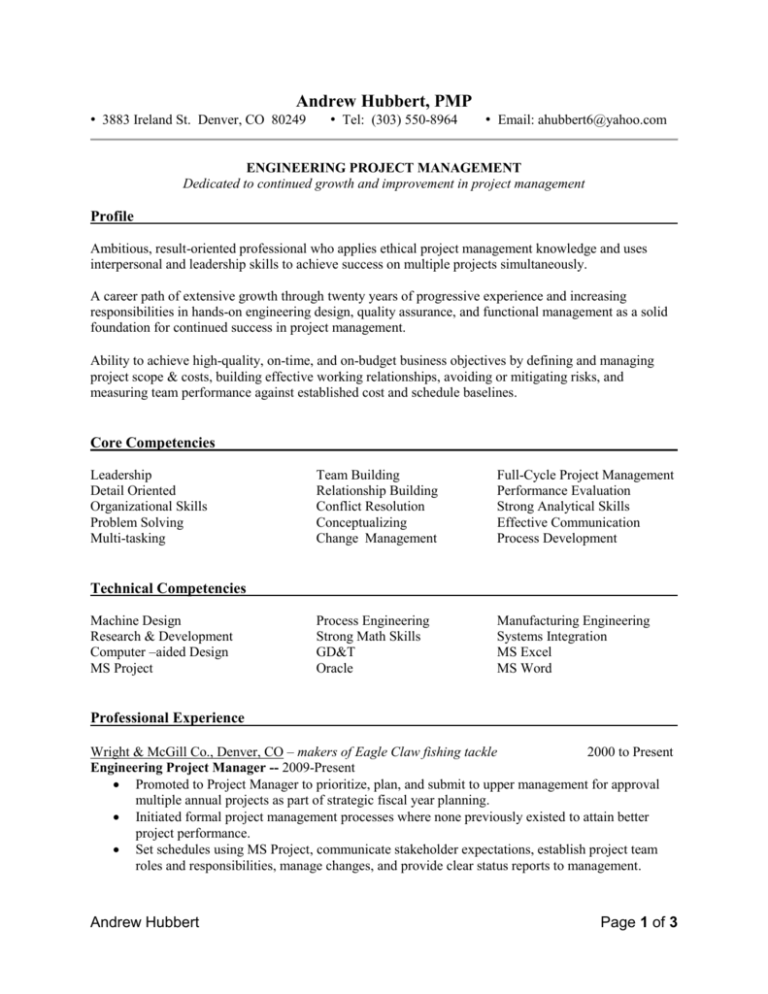

Andrew Hubbert, PMP • 3883 Ireland St. Denver, CO 80249 • Tel: (303) 550-8964 • Email: ahubbert6@yahoo.com ENGINEERING PROJECT MANAGEMENT Dedicated to continued growth and improvement in project management Profile Ambitious, result-oriented professional who applies ethical project management knowledge and uses interpersonal and leadership skills to achieve success on multiple projects simultaneously. A career path of extensive growth through twenty years of progressive experience and increasing responsibilities in hands-on engineering design, quality assurance, and functional management as a solid foundation for continued success in project management. Ability to achieve high-quality, on-time, and on-budget business objectives by defining and managing project scope & costs, building effective working relationships, avoiding or mitigating risks, and measuring team performance against established cost and schedule baselines. Core Competencies Leadership Detail Oriented Organizational Skills Problem Solving Multi-tasking Team Building Relationship Building Conflict Resolution Conceptualizing Change Management Full-Cycle Project Management Performance Evaluation Strong Analytical Skills Effective Communication Process Development Process Engineering Strong Math Skills GD&T Oracle Manufacturing Engineering Systems Integration MS Excel MS Word Technical Competencies Machine Design Research & Development Computer –aided Design MS Project Professional Experience Wright & McGill Co., Denver, CO – makers of Eagle Claw fishing tackle 2000 to Present Engineering Project Manager -- 2009-Present Promoted to Project Manager to prioritize, plan, and submit to upper management for approval multiple annual projects as part of strategic fiscal year planning. Initiated formal project management processes where none previously existed to attain better project performance. Set schedules using MS Project, communicate stakeholder expectations, establish project team roles and responsibilities, manage changes, and provide clear status reports to management. Andrew Hubbert Page 1 of 3 Act as a liaison between sales & marketing and engineering departments to identify project requirements and deliverables. Successfully advance automation technology on a variety of antiquated and chronically problematic high-speed manufacturing processes Quality Control Division Manager Accomplishments: Highlighted the pride of American manufacturing by leading a team that enabled the company to be the only maker in the world of a product new to the industry. Increased productivity 10% and achieved near-zero defects in a difficult brazing manufacturing process by adding a QC vision system. Saved $50,000 by effectively managing a new plating line project accomplished by an in-house team that had no experience in building such processing lines. Assured on-time and on-budget finish of numerous projects totaling in the $1.5 $1.7 million range. Quality Control Supervisor -- 2007-2009 Promoted to QC Supervisor for direct supervision of 11 people including inspectors, testing lab techs, and Engineering specifications techs. Built and maintained programs for vendor qualification and certification. Reviewed resumes and interviewed job candidates, conducted performance evaluations, wrote job descriptions, and resolved conflicts. Accomplishments: Streamlined department processes resulting in more efficient inspections, more timely and informative reporting, less scrap from manufacturing, and higher morale amongst team members. Increased customer satisfaction and retention through direct interactions initiated by complaint calls and letters. Reduced amount of bad product received by suppliers by 50%, thereby reducing number of fines levied by significant customers. Received President’s staff award for outstanding contributions. Senior Design Engineer -- 2000-2007 Improved manufacturing processes such as metal forging & heat treat, plating, packaging, filling & capping of liquid products, and extrusion of dough-based products for consumer sporting goods. Identified areas for needed improvements, researched new and different automation technologies, and integrated those technologies into existing systems or processes. Accomplishments: Increased productivity of a chemical etching line by 50%. Raised the production standard in a packaging process by 100%. Researched and implemented new sustainable packaging resulting in a 10% reduction in shipping and material costs. Dakota Technology Co., Aurora, CO – automation division of Iowa Beef Processors 1999 to 2000 Project Engineer Conceptualized, designed, and installed first-of-its-kind automated cleaning system for a start-up company in the food industry. Andrew Hubbert Page 2 of 3 Provided cost and time estimates, facilitated general construction contractor bidding conferences, coordinated work schedules, resolved technical issues, and promoted teamwork during installation in processing plants. Accomplishments: Reduced amount of needed third shift cleaning crew by 15 people Saved 20 hours of preventive maintenance per month Part of a team that was awarded a patent through original design of the mechanical components of the system Mikron Corporation, Aurora, CO – a global leader in machining & automation solutions 1996 to 1999 Mechanical Engineer Conceptual and detailed computer-aided design of automated assembly systems for the automotive, medical, household appliance, and other industries. Creation of dimensioned drawings with appropriate geometric dimensions and tolerances using AutoCAD. Performed research, development, and assembly of prototype mechanisms. Evaluated and improved systems during the test and debug processes. Prim Hall Enterprises, Inc., Plattsburgh, NY – printing & collating equipment makers 1994 to 1996 Design Engineer Assured the integrity of automated post-press bindery equipment on multiple projects simultaneously through disciplined mechanical design. Increased company revenue by pioneering the design of machines new to the industry. Involved in all project phases from conceptual design to installation at customers’ facilities. Patents U.S. Patent #6,360,874 Automated conveyor cleaning system, Nov. 2002 Education Bachelor of Science Mechanical Engineering -- University of Vermont, Burlington, VT Project Management Certificate Program, 54 contact hrs -- CSU Denver 2012 Professional Certifications & Associations Project Management Professional (PMP) 2012 Member of the Project Management Institute Mile High Chapter REFERENCES AVAILABLE UPON REQUEST Andrew Hubbert Page 3 of 3