1- Ch_1_Introduction

advertisement

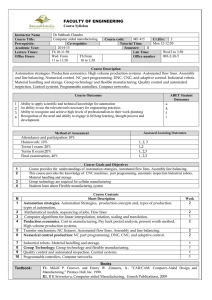

The University of Jordan Mechatronics Engineering Department Automation Chapter 1 Introduction Dr. Osama Al-Habahbah The economic realities of the modern world that affect manufacturing enterprises are: Globalization. International outsourcing . Local outsourcing . Contract manufacturing . Trend towards the service sector in developed economies. Quality expectations. Operational efficiency. Globalization More countries are becoming industrialized, such as China and India, due to their high population and low labor cost . International outsourcing More parts and products are outsourced to companies outside the USA . Local outsourcing Within the same country . Due to specialty of the suppliers, cheaper rate in smaller companies, lack of in-house manufacturing capability Contract manufacturing The customer designs product while the supplier makes the product . Trend towards the service sector in developed economies Erosion of direct manufacturing . Quality expectations Perfect quality is expected Operational efficiency Used to offset the high labor cost Some modern manufacturing technologies that help to compete : • Automation • Material handling technologies • Manufacturing system • Flexible manufacturing • Quality programs • Computer Integrated Manufacturing (CIM) • Lean production Reduces labor cost, decreases production cycle time, and improves quality. Include transportation, storage, tracking . Production line, manufacturing cells. Helps to compete in the low-volume/hig-mix product categories . Such as statistical quality control and six sigma. Includes (CAD) : Computer Aided Design,(CAM): Computer Aided Manufacturing, and integrating computer networks . Accomplish more with less resources increases productivity It is a collection of people, equipment, and procedures to perform the manufacturing operation they are two categories Factory Equipment Layout The set of procedures used by the company to manage production ,such as product design. Facilities Manual work system Using unpowered hand too; Worker machine Automated Using power equipment Automated facility branches out-to: Semi-automated machines and fully automated machines Business function Functions of Manufacturing support system Communicating with customer Product design Either provided by customer or in house if it’s proprietary Manufacturing planning Scheduling, Capacity, planning and process planning Manufacturing planning control Shop floor control Product progress Inventory control Balancing too little and too much inventory Quality control Product quality meets standard Examples include :Automated machine tool that process parts , Automated assembly , Industrial robots , Automatic material handling storage , Automatic quality control (inspection). Minimal change High initial investment , high production rate, inflexibility Fixed automation High initial investment , high production rate, inflexibility Types of automated manufacturing systems flexible programmable High investment , low production rate, flexibility Computer Integrated Manufacturing (CIM) : Such as CAD / CAM Increase labor productivity . Reduce labor cost . Mitigate the effect of labor shortages Reduce manufacturing lead time Accomplish processes that can’t be done manual . To avoid the high cost of not automating (competition) Eliminate routine tasks Improve safety Improve quality It is still needed . It can be preferred to automation in some cases : 1- Task is technologically or economically too difficult to automate . < E.g: hand-eye coordination >. 2- Short product life cycle <Automation takes time>. 3- Customized product . 4- Ups and downs in demand . 5- To reduce risk of products failure < In the market>. 6- Lack of capital to invest in automation. Equipment maintenance Engineering project work Programming and computer operation Plant management. Stand for 1- Specialization of operations: Use of special-purpose equipment for greatest efficiency. 2- Combined operations: Perform more than one operation at a given machine. 3- Simultaneous operations:To reduce processing time. 4- Integration of operations: Linking work-stations together → increasing output 5- Increased flexibility: Maximum utilization of equipment → Use the same equipment for a variety of products. 6- Improved material handling and storage: reduce work in process and shorter manufacturing lead times. 7- On-line inspection: (of quality) reduce scrap and improves quality. 8- Process control and optimization: process time decrease ,quality increase. 9- Plant operations control (of the factory) 10-Computer-integrated manufacturing CIM: ( Design → Operations → Business ) Computer Network Moving from manual to automated. Phase 1 Manual production. Phase 2 Automated production → single-station system. Phase 3 Automated integrated production → multi-station system. Short product introduction time. Gradual automation. Lower risk at the start.