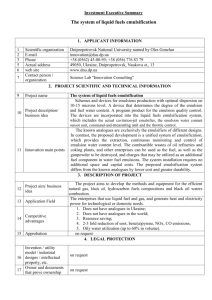

Chapter 6 emulsification and

advertisement

Chapter 6 emulsification and emulsification by surfactants 2006.4.19. §1. Introduction 1. Emulsion – immiscible liquid phase, multiphase dispersion, thermodynamics unstable system (from a few minutes to a few years)– e.g. milk , soybean milk, bearnaise, finishing oil etc. 2. Formation (1) Emulsification – one fluid dispersed in a second dispersephase – 分散相, inner phase , discontinuous phase dispersion medium – 分散介质,outer phase ,continuous phase Three types: o/w, w/o, and w/o/w or o/w/o two immiscible, pure liquids cannot form emulsion. (2) Emulsifying agents – the third component – surfactants 3. Properties (1) Size and aspect of particles Macroemulsions: d>400nm, creamy white Miniemulsions: 400nm>d>100nm, blue-white Microemulsions: 100nm>d>50nm, translucence Nanoemulsions: 50nm<d, transparence (2) Viscosity – Einstein’s eq. = 0 (1 + 2.5) 0 – viscosity of outer phase - volume fraction of inner phase (3) Electric conductivity – outer phase o/w 》w/o , ionics 》nonioncs 4. Differentiation of emulsion types (1) Dilution method (2) Dyeing method (3) Electric conductivity (4) Filter paper method (5) Light reflectance (6) Fluorescence method §2. Theoretics and types of emulsions Conversion in different types of emulsion o/w w/o 1. Phase volume ratio if particles(inner phase) are rigid ball with same size, then volume fraction of inner phase 74.02% water > 74%, then w/o o/w water < 26%, then o/w w/o monodisperse & rigid ball – polydisperse & elastic ball(w/o of oil=99%) 2. Wedge theory – geometry theory Match model 3. Solubility rule – hydrophilicity of surfactants (1) Hydrophilic surfactants – o/w (2) Lyophilic surfactants – w/o 4. Effects of wall (1) Hydrophilic wall (high energy surface) – o/w (2) Lyophilic wall (low energy surface) – w/o 5. Kinetic theory of emulsion type Davies(1957)developed a quantitative theory of emulsion type relating the type of emulsion formed to kinetics of coalescence(聚集) of the two types of droplets present: oil droplets & water droplets Rate of coalescence of the particles: dv/dt = Ae-E/kT A – collision factor; E – energy barrier to coalescence hydrophilic surfactants: Eoli, dv/dt of oil droplets, dv/dt of water droplets, to form o/w emulsions lyophilic surfactants: Ewater, dv/dt of water droplets, dv/dt of oil droplets, to form w/o emulsions 6. Powder for emulsification (1) Condition of emulsification V/L Young’s eq. SV = SL + LV cos Spreading S = SV - SL - LV = LV (cos-1) 0 O/w Young’s eq. SO = SW + OW cosW or SW = SO + OW cosO W+ O=180º SV OW vapor oil liquid SV SL O SO w water SW Spreading SW = SO - SW - OW = OW (cosW-1) 0 or SO = SW - SO - OW = OW (cosO-1) 0 If so ow + sw then W 0, the powder is in water phase If sw ow + so then o 0, the powder is in oil phase Else the powder is adsorbed at O/W interface 0º < W < 180º or 0º < O < 180º (2) According O/w Young’s eq. SO = SW + OW cosW or cosW = (SO - SW)/ OW if SO > SW, W < 90º, hydrophilic , mostly in water phase o/w if SO < SW, W > 90º, lyophilic , mostly in oil phase w/o if SO = SW, W = 90º, balance, o/w or w/o , but unstable §3. Factors of effect on stability of emulsion 1.Reduces of interfacial tension between two liquids e.g. 10ml n-octane(正辛烷) is dispersed in water to 0.1 m emulsion, then its surface area is 300m2, L/L= 50.8mJ/m2, then total surface energy=15.24J if the surfactants are added into the disperse system, then L/L 1 mJ/m2, then total surface energy 0.3J. Dynamic stability 2. Physical nature of the interfacial film (a) Mechanical stability – with strong lateral intermolecular forces and high film elasticity (b) Liquid–crystal formation – with a high-viscosity region and a steric barrier to stabilize of emulsion 3. Existence of an electrical or steric barrier to coalescence on the dispersed droplets (a) Electrical barrier –-potential of ionics: -potential , stability (b) Steric barrier 4. Viscosity of the outer phase - diffusion coefficient of droplets: D=kT/6a - viscosity of the outer phase a – the radius of the droplets , D, stability 5. Size distribution of droplets larger particle have less interfacial surface per unit volume than smaller droplets, so they are thermodynamically more stable than smaller ones. emulsion with uniform size distribution is more stable. §4. Emulsifying agent and HLB value HLB method which was advanced by Griffin in 1949, is the most frequently used method in the selection of emulsifying agents. 1.HLB value – Hydrophilic-Lipophilic Balance HLB = Hydrophilic portion/Lipophilic portion = 0 ~ 40 Paraffin ~ 0, sodium dodecyl sulfate ~ 40 HLB value < 10 lipophilic HLB value >10 hydrophilic HLB value for typical nonionic surfactants structures 2. HLB value 1~3 3~6 7~9 8 ~ 18 13 ~15 15 ~18 & application anti-foaming agent w/o emulsifying agents wetting agents o/w emulsifying agents detergents solubilizing agents 3. Estimate of HLB value (1)Nonionics: HLB = mass fraction of hydrophilic group20 (a) Fatty acid of many polyhydric alcohols(多元醇) HLB = 20(1-S/A) S – saponification number(皂化值) of the ester; A – acid number(酸值) of the fatty acid in the ester. e.g. C17H35COOCH2CH(OH)CH2OH S=161, A=198, then HLB = 3.7 (b) Nonionics of POE & polyol HLB = (E + P)/5 E – the weight percentage of oxyethylene content P – the weight percentage of polyol content e.g. C16H33(OC2H4)10OH E = (44 10+17)/(44 10+17+225) = 67.0%;P = 0 HLB = (E+P)/5 = 67.0/5 = 0.67 20 = 13.4 (c) Logarithm: HLB=7+11.7ln(MW/MO) MW or MO- molecular weight of hydro- or lipo-philic group: MW=441, MO=225, then HLB=14.9 (2) Ionic surfactants – group numbers could be calculated based upon group contribution accord-ing to the formula: HLB = 7 + (group numbers) e.g.C12H25SO4Na HLB=7+38.70.47512=40 e.g. C16H33(OC2H4)10OH HLB=7+0.33 10+0.50.475 16=3.20 (3) Mensuration (a) behavior in water no dispersibility poor dispersion milky dispersion after vigorous agitation stable milky dispersion (upper end almost translucent) from translucent to clear clear solution HLB Range 1–4 3–6 6–8 8 – 10 10 – 13 13 + (b) Cloud point – POE nonionics 1% aq. TP , HLB, TP>100ºC, HLB>15, TP HLB (4) HLB of a mixyure HLBmix= fiHLBi =fAHLBA+(1-fA)HLBB fi – the weight fraction of surfactant i in mixture 4. Emulsifying agents (1) Synthetical surfactants (a) Anionics – HLB > 8 , o/w type (b) Nonionics – HLB < 18, o/w or w/o type (c) Cationics - a few (2) Natural surfactants – lecithin(卵磷脂), cholesterin(胆甾醇) etc (3) Polymeric emulsifying agents (4) Powder emulsifying agents 5. Application - selection of surfactants using HLB value as emulsifying agents (1) Optimal HLB value for emulsification (A)Using the data handbook (a) HLB value for emulsification of some oils (b) Mixture of oils HLBmix= Fj HLBj= FAHLBA+(1-FA)HLBB Fj ,HLBj – weight fraction and HLB of j oil. (B) Mensuration and check e.g. using the Span-series (HLBSpen-60=4.3) and Tween-series (HLBTween-80=15), the optimal HLB value for emulsification (2) Optimal emulsifying agents – two principles (a) The structure of hydrophobic groups of emulsifying agents is close to the oils (b) The synergistic effect 6. Phase Inversion Temperature (相转变温度PIT) (1) Disadvantage of HLB method (a) Surfactants with same HLB value could possess different emulsifying ability (b) It makes no allowance for the change in HLB value with change in the conditions for emulsification (temperature, nature of oil & water phase). E.g. POE T, HLB (2) PIT – the temperature when the POE is used to emulsifying agents from o/w emulsion inversion to w/o (3) Mensuration of PIT – emulsion : 3-5% emulsifying agents and o:w volume ratio =1 (4) Emulsion stability (a) o/w type : PIT – TS =20-60ºC TS – storage temperature (储藏温度)of emulsion (b) w/o type : TS – PIT = 10-40ºC (c) Preparing temperature of emulsificatopn by the PIT Preparation at a temperature 2-4ºC below the PIT to obtain a very fine average particles size Cooled down to storage temperature( for o/w) to increases it stability (5) Factors affecting PIT (a) PIT HLB selection of emulsion PIT according to their HLB value (b) Hydrophility of POE , PIT (c) Distribution of POE , PIT, o/w stability (d) Addition of electrolyte in water phase, PIT (e) In oil phase addition of nonpolar organics e.g. paraffin PIT addition of polar organics e.g. long chain, PIT short chain, PIT Mixture of oils PITmix= i PITi = A PITA + (1- A) PITB i – volume fraction of i oil; PITi – PIT of i oil in this emulsifying system 7. Preparation method of emulsion (1) (a) (b) (c) (d) Addition of emulsifying agents in water phase in oil phase nascent soap(初生皂法) mixed films (respectively addition of hydrophilic surfactants in water and hydrophobic surfactants in oil phase) (e) alternately addition of oil and water (2) Oil-Water mixing (a) The addition of water to oil - to obtain a very fine average particles size and stable o/w emulsion (b) The addition of oil to water (3) Methods of emulsification (a) Direct emulsification – 70 - 75ºC (b) Phase inversion emulsification (4) Equipment of emulsification (a) Simple agitating - impulse type (推进式), turbo type(涡轮式) (b) Homogenizer – high pressure 6.89-34.47 Mpa (c) Colloid mill (胶体磨) – rotor(转子) and stator(定 子), rotate speed = 1000-20000 rpm ,high shearing force (高切力) §5. instability of emulsion and demulsification 1. (1) (2) (3) (4) Inversion of emulsion – o/w w/o Phase volume ratio Polyvalent ions Temperature T>PIT Addition of electrolytes o/w w/o e.g. Inversion of o/w to w/o by an interface film of sodium cetyl sulfate (十六烷基硫酸钠) and cholesterol (胆固醇)upon addition of polyvalent cations 2. The creaming(分层), flocculation(絮凝),and coalescence(聚结) – the reversible prelude of emulsion breaking (a) Creaming – difference in gravitational (b) Flocculation - attractive force between droplets (c) Coalescence – irreversible - breaking, phase separation 3. Emulsion breaking(破乳) – to break the interface films (1) Methods (a) Physical method Heating Electrical precipitation Ultrasonic (b) Chemical method De-emulsifying agent Inorganic acid Polyvalent ion to inversion (2) Mechanism (a) Displacing – emulsifying agents are displaced by de-emulsifying agent (b) Wetting – powder emulsifying agents (c) Flocculating – cross-linking agents (d) Collision - deemulsification (e) Make the interface film to distortion(变形) and tendering(变脆) (3) Factor affecting de-emulsification (a) pH value – e.g. carboxylate surfactant is unstable at low pH. (b) Electrolyte Concentration – I , , stability. Valenta value – polyvalent ion , stability (c) Temperature - T, solubility of surfactants, intensity of film (d) Phase volume ratio – volume fraction > 74.02% (h) Stirring – Reynolds number (雷诺数) - 3500 §6. Micro-emulsion Generally : surfactants & cosurfactants and etc In 1986,the cosurfactant-free microemulsion have been prepared • The differentia with macro-emulsion 2. Mechanism of formation (1) Negative interfacial tension theory – Schulman and co-workers: 0 spontaneous process it may be a transient phenomenon(暂时), and at equilibrium must be zero or slightly positive. is macroscopy property and made no sense in micro-emulsion oil (2) 双重膜(duplex film?) mo surfactants + co-surfactants Mixed film mw + auxiliary agent(助剂) water If mw mo, then the films is bended to water phase, w/o If mw < mo, then the films is bended to oil phase, o/w (3) Swollen micelles