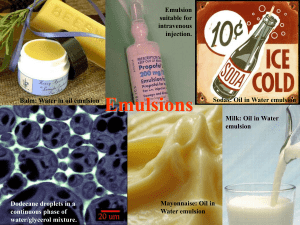

EMULSION

advertisement

Combine two immiscible liquid phases one of which is dispersed as globules (the dispersed phase) in the other liquid phase (the continuous phase) stabilized by presence of emulsifying agent. 1. They can mask the bitter taste and odor of drugs, e.g. castor oil, cod-liver oil etc. 2. They can be used to prolong the release of the drug thereby providing sustained release action. 3. Essential nutrients like carbohydrates, fats and vitamins can all be emulsified and can be administered to bed ridden patients as sterile intravenous emulsions. 4. Emulsions provide protection to drugs which are susceptible to oxidation or hydrolysis. 6. Emulsions are used widely to formulate externally used products like lotions, creams, liniments etc. Based on type: 1- Oil in water emulsions (O/W) 2- Water in oil emulsions (w/O) 3- Multiple emulsions (O/W/O) or (W/O/W) Based on size of dispherse phase: 1. macroemulsion 2. microemulsion (nanoemulsion) 1. It should be able to reduce the interfacial tension between the two immiscible liquids. 2. It should be physically and chemically stable , inert and compatible with the other ingredients of the formulation. 3. It should be non irritant and non toxic in the conc., used. 4. It should be able to produce and maintain the required viscosity of the preparation. 5. It should be able to form a coherent film around the globules of the dispersed phase and should prevent the coalescence of the droplet of the dispersed phase. 1-Natural emulsifying agents (vegetable source) acacia - tragacanth- pectin- starch, derivative of cellulose (semisintetic) (animal source) gelatin- cholesterol – lecitin, wool fat Advantages: Non toxic and relatively inexpensive Disadvantages: They show considerable batch to batch variation readily support M.O. growth 2- Finely divided solid: Mg(OH)2, bentonite, aluminium magnesium stearate, attapulgite, colloidal anhydrous silica and hectorite forming a coherent film which physical prevents coalescence of the dispersed globules. if the particles are: preferntially wetted by the aqueous phase o/w emulsion preferntially wetted by the oil phase w/o emulsion 3- Synthetic emulsifying agents as: A- Anionic emulsifying agents Alkali soap: e.g. sodium, potassium and ammonium salts of fatty acids Form o/w emulsions in acidic condition precipitated incompatible with polyvalent cations Soap of di/trivalent metal - e.g. Cal oleate - Promote w/o emulsions Amine soaps: N(CH2CH2OH)3 - neutral pH - incompatible with acids and high concentration of electrolytes - Produce o/w emulsion Sulfated and sulfonated compound - E.g.Sodium lauryl sulphate - stable over high pH range - o/w emulsions B- Cationic surfactants Quaternary ammonium compounds: E.g. Cetyl trimethylammonium bromide (Cetrimide) and benzalkonium chloride Disadvantages: Toxicity and irritancy Incompatible with anionic surfactants, polyvalent anions unstable at high pH C- Nonionic surfactants Low toxicity and irritancy so suitable for oral and Parenteral administeration High degree of compatibility Less sensitive to change pH or to addition of electrolytes E.g. Tweens (polyethylene fatty acid ester) Span ( sorbitan fatty acid ester) glyceryl monostearate, propylene glycol monostearate, macrogol esters such as polyoxyl stearates and polyoxyl-castor oil derivatives D- Amphoteric surfactants charge depending on the pH of the system low pH cationic high pH anionic i.e. lecithin: used to stabilize i.v., fat emulsion HLB: the ratio between the hydrophilic portion of the molecule to the lipophilic portion of the molecule. The higher the HLB of an agent the more hydrophilic it is. Griffin equation: HLB = 20 (1 – S / A) S: saponification number of the ester A: the acid number of the fatty acid Davis equation: HLB = hydrophilic group number + lipophilic group number + 7 1. Physical nature of the interfacial surfactant film For Mechanical stability, surfactant films are characterized by strong lateral intermolecular forces and high elasticity (Analogous to stable foam bubbles) 2. Electrical or steric barrier Significant only in O/W emulsions. In case of non-ionic emulsifying agents, charge may arise due to (i) adsorption of ions from the aqueous phase or (ii) contact charging (phase with higher dielectric constant is charged positively) No correlation between droplet charge and emulsion stability in W/O emulsions 3. Viscosity of the continuous phase 4. Size distribution of droplets 5. Phase volume ratio As volume of dispersed phase stability of emulsion (eventually phase inversion can occur) 6. Temperature Temperature , usually emulsion stability Temp affects – Interfacial tension, solubility of surfactant, viscosity of liquid, phases of interfacial film 1. Dilution test 2. Conductivity Test 3. Dye-Solubility Test 4. Fluorescence test : 4. Fluorescence test oils give fluorescence under UV light, while water doesn’t. Therefore, O/W emulsion shows spotty pattern while W/O emulsion fluoresces. 1. Continental or dry gum method Emulsifier is triturated with the oil in perfectly dry porcelain mortar water is added at once triturate immediately, rapidly and continuously (until get a clicking sound and thick white cream is formed, this is primary emulsion) the remaining quantity of water is slowly added to form the final emulsion 2. English or Wet Gum Method triturate gum with water in a mortar to form a mucilage oil is added slowly in portions the mixture is triturated after adding all of the oil, thoroughly mixed for several minute to form the primary emulsion Once the primary emulsion has been formed remaining quantity of water is added to make the final emulsion 3. Bottle or Forbes Bottle Method It is extemporaneous preparation for volatile oils or oil with low viscosity. gum + oil (dry bottle) Shake water (volume equal to oil) is added in portions with vigorous shaking to form primary emulsion remaining quantity of water is added to make the final emulsion a) Flocculation and creaming Creaming related to stokes equations Explain its!! The solution is….. b) coalescence and breaking/cracking c) Phase inversion d) Miscellaneous physical and chemical change It may be brought about by: 1- the addition of an electrolyte e.g. addition of CaCl2 into o/w emulsion formed by sodium stearate can be inverted to w/o. 2- by changing the phase volume ratio 3- by temperature changes. Phase inversion can be minimized by: 1- using the proper emulsifying agent in adequate concentration 2- keeping the concentration of dispersed phase between 30 to 60 % 3- storing the emulsion in a cool place Cracking of emulsion can be due to: 1- addition of an incompatible emulsifying agent , e.g. monovalent soap + divalent soap e.g. anionic + cationic emulsifying agent 2- chemical or microbial decomposition of emulsifying agent e.g. alkali soaps decomposed by acids e.g. monovalent soaps salted out by electrolytes such as NaCl e.g. nonionic emulsifying agents are incompatible with phenols e.g. alcohol precipitates gums and gelatin 3- exposure to increased or reduced temperature 4- Addition of common solvent e.g. addition of a solvent in which the two phases are soluble (alcohol) Contamination due to microorganisms can result in problems such as: 1- color and odor change 2- gas production 3- hydrolysis 4- pH change 5- breaking of emulsion 1. Determination of count 2. Determination of 3. Determination of 4. Determination of properties particle size and particle viscosity phase separation: electrophoretic