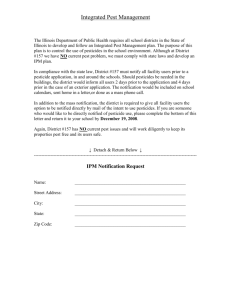

ACRONYMS - Documents & Reports

advertisement