4 News Articles which relate to operations topic

advertisement

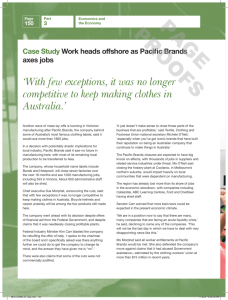

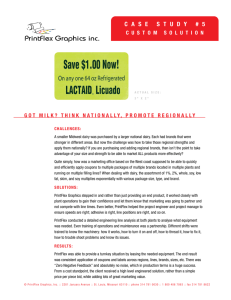

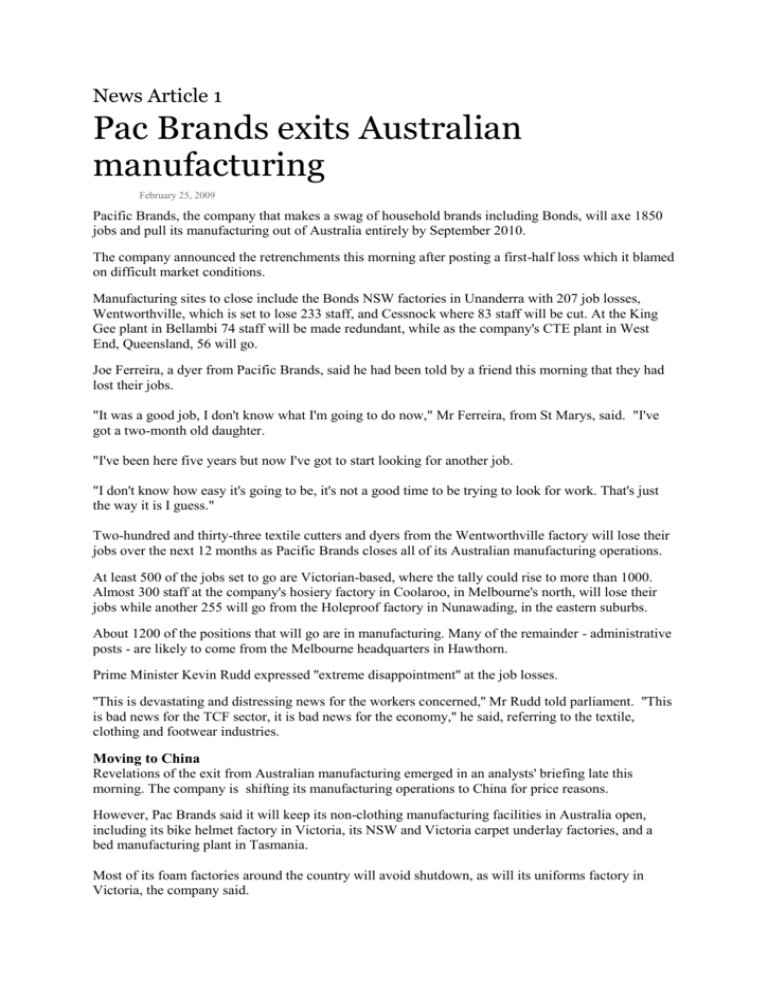

News Article 1 Pac Brands exits Australian manufacturing February 25, 2009 Pacific Brands, the company that makes a swag of household brands including Bonds, will axe 1850 jobs and pull its manufacturing out of Australia entirely by September 2010. The company announced the retrenchments this morning after posting a first-half loss which it blamed on difficult market conditions. Manufacturing sites to close include the Bonds NSW factories in Unanderra with 207 job losses, Wentworthville, which is set to lose 233 staff, and Cessnock where 83 staff will be cut. At the King Gee plant in Bellambi 74 staff will be made redundant, while as the company's CTE plant in West End, Queensland, 56 will go. Joe Ferreira, a dyer from Pacific Brands, said he had been told by a friend this morning that they had lost their jobs. "It was a good job, I don't know what I'm going to do now," Mr Ferreira, from St Marys, said. "I've got a two-month old daughter. "I've been here five years but now I've got to start looking for another job. "I don't know how easy it's going to be, it's not a good time to be trying to look for work. That's just the way it is I guess." Two-hundred and thirty-three textile cutters and dyers from the Wentworthville factory will lose their jobs over the next 12 months as Pacific Brands closes all of its Australian manufacturing operations. At least 500 of the jobs set to go are Victorian-based, where the tally could rise to more than 1000. Almost 300 staff at the company's hosiery factory in Coolaroo, in Melbourne's north, will lose their jobs while another 255 will go from the Holeproof factory in Nunawading, in the eastern suburbs. About 1200 of the positions that will go are in manufacturing. Many of the remainder - administrative posts - are likely to come from the Melbourne headquarters in Hawthorn. Prime Minister Kevin Rudd expressed ''extreme disappointment'' at the job losses. ''This is devastating and distressing news for the workers concerned,'' Mr Rudd told parliament. ''This is bad news for the TCF sector, it is bad news for the economy,'' he said, referring to the textile, clothing and footwear industries. Moving to China Revelations of the exit from Australian manufacturing emerged in an analysts' briefing late this morning. The company is shifting its manufacturing operations to China for price reasons. However, Pac Brands said it will keep its non-clothing manufacturing facilities in Australia open, including its bike helmet factory in Victoria, its NSW and Victoria carpet underlay factories, and a bed manufacturing plant in Tasmania. Most of its foam factories around the country will avoid shutdown, as will its uniforms factory in Victoria, the company said. The company's net loss for the six months to December 31 was $150 million, compared to a profit of $57 million in the previous corresponding period. Pac Brands manufactures household brand names including Holeproof, Dunlop, Stussy, Mossimo, Berlei and Hard Yakka - and its public faces include former tennis ace Pat Rafter and supermodel Sarah Murdoch. Exit from brands PacBrands also plans to shut down a number of smaller brand names in the face of ongoing difficult economic conditions. The heavily-indebted company said it had made the decision because there was "no long-term sustainable advantage from local manufacturing'', and that "efforts to make (its facilities) cost efficient (were) no longer relevant''. That came as new data revealed skilled job vacancies slumped a further 11% in February. The Department of Education, Employment and Workplace Relations skilled vacancies index in February was 46.4 points, 52.4% lower than in February 2008. Most of the jobs lost will be relocated to cheap labour economies, most likely in Asia. The company will close down the majority of its clothing manufacturing facilities across the world - including a factory in China - and will instead rely on sourcing products from other suppliers. Investors initially supported the changes, but dumped the stock in afternoon trading. Pacific Brands shares shed 13 cents, or 37%, to close at 22 cents. Union criticises redundancies But the Textile, Clothing and Footwear Union's Michele O'Neil says the closures aren't justified. She has made an urgent call for high-level meetings in a bid to save jobs. "We don’t accept that this decision is justified,” Ms O'Neil said. "This company has received million of dollars of government assistance over many years. And some of these businesses are profitable." "We’re calling on the Federal Government and the company to urgently meet with the union to see if some of these jobs can be saved." The company's board said it would not pay its shareholders a dividend in order that as much cash as possible could be preserved. A decision on the final dividend for the 2009 financial year will be made according to business conditions at the time. Uncertain future Pacific Brands chief executive Sue Morphet described the first half result as "solid" and in line with the company's guidance. The current economic climate remains challenging and uncertain, with consumer confidence at low levels, she said. "The potential for the continuation of deterioration in the market means we are not in a position to confidently predict the second half performance," she said. Revenue for the first half fell 5.2% to $1.04 billion, with earnings before interest, tax and amortisation (EBITA) up 0.3% to $113 million. The company's EBITA margin climbed 0.4% to 10.8% on a 0.8% rise in its gross margin to 44.7%. Pacific Brands has extended the maturity date of its earliest maturing debt facilities, currently worth $550 million, until August 2010. The third tranche of debt, worth $250 million, matures on March 28, 2012. Ms Morphet said Pacific Brands will implement a new strategy, dubbed Pacific Brands 2010, to restructure the business, fold smaller brands to cut costs and complexity and shut down some clothing manufacturing in Australia. "Unfortunately these changes will necessitate 1850 jobs losses in Australia over an 18-month period including 1200 in clothing manufacturing,'' she said. "The reduction in complexity will deliver the future strength, growth, profitability and sustainability of the business - for our shareholders and employees.'' The company says the new strategy will deliver $150 million a year in cost savings by full year 2011 after an overhaul of sourcing, including closing the majority of its Australian clothing manufacturing operations. As well, Pacific Brands will offload non-core businesses, sell properties, relocate some head office functions and consolidate office space. One-off expenses of around $110 million would be incurred in the second half of 2009 with another $15 million in full year 2010 and 2011, the company said in a statement. The company will use increased operating cashflow to pay down debt. This may be complemented by asset sales, and would determine the most appropriate debt facilities for the newly structured business, Ms Morphet said. Questions: 1) Describe the influences on operations that have lead Sue Morphet to make the decision to move the company’s operations overseas to China. ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ 2) Explain ONE operations strategy being used by Sue Morphet and how this should lead to increased profitability for her company. ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ ______________________________________________________________ News Article 2 NSW changes rules on mobile phone car use October 31, 2012 7:29AM LAWS tightening regulations about using mobile phones in cars will begin on Thursday, prompting NSW police to issue a warning to motorists. From Thursday, people will only be able to use a phone while driving if it is secured in a cradle fixed to the vehicle or can be operated without touching any part of the phone by using technology like Bluetooth, police said. "The new laws make it clear that a driver cannot hold a phone in his or her hand other than to pass it to a passenger," police said in a statement. "Furthermore, under the new laws, drivers cannot rest mobile phones on their legs or hold it between their shoulder and ear." It's still OK to use the phone to make or receive calls, play music and use GPS, so long as it's kept in a cradle. But that's only if you hold a full licence. Under the new laws, learner and P1 drivers are banned from using any function on the phone. NSW highway patrol Assistant Commissioner John Hartley said the new rules would clear up confusion and improve road safety and warned drivers to be careful about using phones behind the wheel. "The penalty for illegally using a mobile phone while driving is three demerit points and a $298 fine," he said in a statement. "This is upgraded to four demerit points and a $397 fine if the offence occurs in a school zone." New rules about roundabouts, overtaking and giving way to pedestrians will also be introduced on Thursday, he said. Information about the new laws can be found on the RTA's website. Questions 1) Describe the influence on operations that will impact the operations manager at companies who manufacture mobile phone cradles. ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ 2) Explain the influence on the transformation process that is most relevant to the operations at companies who manufacture mobile phone cradles. ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ 3) Outline three elements of quality management that would need to be adopted to ensure that the increased production of mobile phone cradles meets the quality standards expected by consumers. ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ __________________________________________________________________ News Article 3 Toyota to recall 300,000 cars in Australia, 7.4 million worldwide Save this story to read later by: Neil Dowling From: News Limited Network ALMOST 300,000 Toyotas are heading back to the dealership after Toyota Australia today issued its biggest ever recall. As part of worldwide recall of some 7.4 million vehicles, Toyota is recalling Corolla, Klugers, RAV4, Yaris, Aurion and Camry cars built between 2006 and 2010. The latter two are made in Australia. The recall is to replace the electric window master switch, located on the driver's armrest. Toyota warned that attempts to fix the fault could result in the switch overheating and melting. There have been six reported cases in Australia from a total of 297,931 vehicles specified by Toyota Australia. It says the problem is that the switch doesn't operate smoothly and has a ''sticky feel''. “This is due to the non-uniform application of lubricating grease resulting in wear to the internal sliding contact points,'' says the recall notice. “In some instances, the switch may become inoperative.'' Toyota spokeswoman Beck Angel cautioned against using commercial lubricants as a fix. “This recall is a precautionary measure,'' she says. ''The switch will be checked mechanically and electrically for correct operation and specialised electrical grease will then be applied to ensure it operates smoothly when pressed.'' Some vehicles will require the window's electrical circuit board to be replaced. “The inspection and any required repairs will take approximately one hour to complete and will be at no cost to the owner,'' Ms Angel says. “Depending on the dealer's work schedule however, the car may need to be available for a longer period of time. Should Toyota owners experience sticking operation of the power window master switch, we recommend that the switch is no longer used prior to vehicle inspection and repair.'' Toyota will start a mailout to owners of affected vehicles at their last known address from mid-November asking them to make an appointment with their preferred Toyota dealer. Questions 1) Outline ONE influence on operations that is most relevant to the story above. ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ 2) Define the term warranty and explain the implications for the operations manager of the service department at Toyota Dealerships given this news story. ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ ________________________________________________________________ 3) Define quality assurance and evaluate how successful this process has been at Toyota. ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ News Article 4 Costco vs the Supermarkets in the UK Questions 1) Outline an influence on operations is being shown in the above graph ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ 2) Which approach to the strategic role of operations is being pursued by Costco? ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ __________________________________________________________________ 3) Explain an operations strategy that is being used by Costco to drive prices lower than their competitors. ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________ ___________________________________________________________________