Measuring Process Variability

advertisement

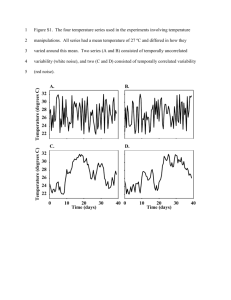

Variability Definition: Variability is anything that causes the system to depart from regular, predictable behavior. Sources of Variability: • • • • • • machine failures setups material shortages yield loss rework operator unavailability © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 May be consequence of manufacturing practices • workpace variation • differential skill levels • material handling • demand fluctuations • engineering change orders • product variety www.factoryphysics.com May be consequence of business strategy 1 Measuring Process Variability te mean process time of a job σ e standard deviation of process time ce e te coefficien t of variation , CV Note: we often use the “squared coefficient of variation” (SCV), ce2 © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 2 Measuring Process Variability – Example Trial 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 te se ce Class © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 Machine 1 22 25 23 26 24 28 21 30 24 28 27 25 24 23 22 25.1 2.5 0.1 LV Machine 2 5 6 5 35 7 45 6 6 5 4 7 50 6 6 5 13.2 15.9 1.2 MV www.factoryphysics.com Machine 3 5 6 5 35 7 45 6 6 5 4 7 500 6 6 5 43.2 127.0 2.9 HV 3 Flow Variability Process Variability is bad enough… • Inflates FT • Inflates WIP • Forces lower utilization of capacity But, variability also propagates… • Causes uneven arrivals downstream • Inflates FT and WIP at other stations • Forces lower utilization of capacity throughout the line © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 4 Illustrating Flow Variability Low variability arrivals t High variability arrivals t © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 5 Propagation of Variability – Low Utilization Station LV HV LV HV HV HV LV LV LV HV LV HV Conclusion: flow variability out of a low utilization station is determined primarily by flow variability into that station. © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 6 Propagation of Variability – High Utilization Station LV HV HV HV HV HV LV LV LV HV LV LV Conclusion: flow variability out of a high utilization station is determined primarily by process variability at that station. © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 7 Propagation of Variability ce2(i) ca2(i) cd2(i) = ca2(i+1) i i+1 Single Machine Station: c u c (1 u )c 2 d 2 2 e 2 2 a where u is the station utilization given by u = rate Multi-Machine Station: departure var depends on arrival var and process var u2 2 c 1 (1 u )(c 1) (ce 1) m rt where m is the number of (identical) machines and u a e m 2 d © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 2 2 a www.factoryphysics.com 8 Kendall's Classification A/B/C B A: arrival process B: service process C: number of machines A Queue M: exponential (Markovian) distribution C Server G: completely general distribution D: constant (deterministic) distribution. © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 9 The G/G/1 Queue Formula: FTq V U t ca2 ce2 u te 2 1 u Observations: • • • • Useful model of single machine workstations Separate terms for variability, utilization, process time. FTq (and other measures) increase with ca2 and ce2 Flow variability, process variability, or both can combine to inflate queue time. • Variability causes congestion! © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 10 Seeking Out Variability General Strategies: • • • • • look for long queues (Little's law) look for blocking focus on high utilization resources consider both flow and process variability ask “why” five times Specific Targets: • • • • • equipment failures setups rework operator pacing anything that prevents regular arrivals and process times © Wallace J. Hopp, Mark L. Spearman, 1996, 2000 www.factoryphysics.com 11