TOTAL QUALITY MANAGEMENT: TQM Origins

advertisement

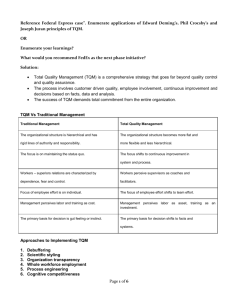

TOTAL QUALITY MANAGEMENT: TQM Origins, Evolution & key elements What is Quality? Quality is “fitness for use” (Joseph Juran) Quality is “conformance to requirements” (Philip B. Crosby) Quality of a product or services is its ability to satisfy the needs and expectations of the customer Evolution of Quality Management Inspection Salvage, sorting, grading, blending, corrective actions, identify sources of non-conformance Quality Control Develop quality manual, process performance data, self-inspection, product testing, basic quality planning, use of basic statistics, paperwork control. Quality Assurance Quality systems development, advanced quality planning, comprehensive quality manuals, use of quality costs, involvement of non-production operations, failure mode and effects analysis, SPC. TQM Policy deployment, involve supplier & customers, involve all operations, process management, performance measurement, teamwork, employee involvement. W. E. Deming and the 6 Era’s of Quality 1920’s : New statistical thinking and methods in manufacturing 1930/40’s : Use of statistical thinking outside manufacturing 1950/60’s : Systems of improvement 1970/80’s : The fourteen points Late 80’s : The “New Climate” 1990’s : System of Profound Knowledge Deming’s view of a production as a system Receipt & test of materials Suppliers, materials & equipment Production, assembly, inspection Design & redesign Distribution Test of processes, machines, methods, cost Consumer Research Consumers Deming’s Chain Reaction Improve Quality Provide jobs and more jobs Stay in business Cost decreases because of less rework, fewer mistakes, fewer delays, snags, better use of machine time and materials Productivity improves Capture the market with better quality and lower price The Deming Cycle or PDCA Cycle PLAN Plan a change to the process. Predict the effect this change will have and plan how the effects will be measured ACT DO Adopt the change as a permanent modification to the process, or abandon it. Implement the change on a small scale and measure the effects CHECK Study the results to learn what effect the change had, if any. W. Edwards Deming’s 14 Points 1) Create constancy of purpose towards improvement of product and services. 2) Adopt the new philosophy. We can no longer live with commonly accepted levels of delays, mistakes, defective workmanship. 3) Cease dependence on mass inspection. Require, instead, statistical evidence that quality is built in. 4) End the practice of awarding business on the basis of price tag. W. Edwards Deming’s 14 Points 5) Find problems. It is management’s job to work continually on the system. 6) Institute modern methods of training on the job. 7) Institute modern methods of supervision of production workers. The responsibility of foremen must be changed from numbers to quality. 8) Drive out fear that everyone may work effectively for the company. W. Edwards Deming’s 14 Points 9) Break down barriers between departments. 10) Eliminate numerical goals, posters and slogans for the workforce asking for new levels of productivity without providing methods. 11) Eliminate work standards that prescribe numerical quotas. 12) Remove barriers that stand between the hourly worker and his right to pride of workmanship. W. Edwards Deming’s 14 Points 13) Institute a vigorous programme of education and retraining. 14) Create a structure in top management that will push everyday on the above 13 points. Deming’s System of Profound Knowledge Appreciation for system Theory about knowledge Knowledge about variation Knowledge of psychology Philip Crosby’s Four Absolutes What is Quality? Definition : Conformance to requirements What system is needed to cause quality? System of quality is prevention What performance standard should be used? Performance Standard : Zero Defects What measurement system is required? Measurement : Price of nonconformance (PON) Crosby’s Successful Company Characteristics of the Eternally Successful Organisation People do things right routinely Growth is profitable and steady Customer needs are anticipated Change is planned and managed People are proud to work there Philip B. Crosby’s 14 Points 1) Make it clear that management is committed to quality. 2) Form quality improvement teams with representatives from each department. 3) Determine where current and potential quality problems lie. 4) Evaluate the cost of quality and explain its use as a management tool. Philip B. Crosby’s 14 Points 5) Raise the quality awareness and personal concern of all employees. 6) Take actions to correct problems identified through previous steps. 7) Establish a committee for the zero defects programme. 8) Train supervisors to actively carry out their part of the quality improvement programme. Philip B. Crosby’s 14 Points 9) Hold a ‘zero defects day’ to let all employees realise that there has been a change. 10) Encourage all individuals to establish improvement goals for themselves and their groups. 11) Encourage employees to communicate to management the obstacles they face in attaining their improvement goals. 12) Recognise and appreciate those who participate. Philip B. Crosby’s 14 Points 13) Establish quality councils to communicate on a regular basis. 14) Do it all over again to emphasise that the quality improvement programme never ends. Joseph M. Juran’s Quality Trilogy Quality Planning Establish quality goals Identify customer needs Translate needs into our language Develop a product for these needs Optimise product features for these needs Quality Control Quality Prove the process can Improvement produce under operating conditions Transfer process to operation Seek to optimise the process via tools of diagnosis Juran’s Trilogy Diagram Quality Planning Quality control (during operations) 40 Cost of Poor Quality Quality improve -ment 20 Original zone of quality control 0 TIME 0 Lessons learned New zone of quality control Juran’s Quality Planning Road Map 1) Identify who are the customers 2) Determine the customer’s needs 3) Translate the needs into our language 4) Develop a product to meet those needs 5) Optimise a product so as to meets our needs as well as the customer’s. 6) Develop a process which is able to produce the product 7) Optimise the process 8) Prove the process can make the product under operating conditions Joseph M.Juran and the Cost Of Quality 2 types of costs: Unavoidable Costs: preventing defects (inspection, sampling, sorting, QC) Avoidable Costs: defects and product failures (scrapped materials, labour for re-work, complaint processing, losses from unhappy customers “Gold in the Mine” Joseph M.Juran and the Cost Of Quality Costs Total Costs Unavoidable costs Avoidable costs 100% defective Point of “Enough quality” Joseph M. Juran’s 10 Points 1) Build awareness of the need and opportunity for improvement. 2) Set goals for improvement. 3) Organise to reach the goals (establish a quality council, identify problems, select projects, appoint teams, designate facilitators) 4) Provide training. 5) Carry out projects to solve problems Joseph M. Juran’s 10 Points 6) Report progress. 7) Give recognition. 8) Communicate results. 9) Keep score. 10) Maintain momentum by making annual improvement part of the regular systems and process of the company. What is TQM? Constant drive for continuous improvement and learning. Result Focus Actions not just words (implementation) Management by Fact Passion to deliver customer value / excellence Process Management Concern for employee involvement and development Organisation response ability Partnership perspective (internal / external) LEARNING AND TQM Learning Process Improvement Quality Improvement Customer Satisfaction Shareholder Satisfaction Employee Satisfaction BASIC PRINCIPLES OF TQM Approach Scope Scale Management Led Company Wide Everyone is responsible for Quality Philosophy Prevention not Detection Standard Right First Time Control Cost of Quality Theme On going Improvement FOUR KEY PRINCIPLES •Measure quality so you can affect it •Focus on a moving customer •Involve every employee •Think long term - Act short term THE CASE FOR QUALITY 1 Success of competitors who take quality seriously 2 Rising expectations of customers 3 Quality differentiates companies from the competition 4 Narrowing of supplier bases by quality conscious companies . THE CASE FOR QUALITY 5 Growing evidence that growth in market share comes from sustained quality. 6 Cost advantages 7 High cost of catastrophic failure 8 Inspection poor substitute for right first time SEVEN DEADLY SINS OF TQM •Flight to nowhere •One size fits all •Substituting TQM for leadership •Inside - Out indicators •Mandatory religion •Quality kept as a separate activity •Teaching to the test Booz-Allen & Hamilton IS QUALITY A SOUND INVESTMENT? Year 1988 1988 1989 1990 1990 1990 1991 1992 1992 1992 1993 1994 Company Stock Growth (Oct 94) Motorola 373.0% Westinghouse (CNFD) - 49.6% Xerox (BPS) 75.9% General Motors 1.6% Federal Express 10.6% IBM (IBM Rochester) - 34.9% Selectron 526.9% AT&T (UCS) 32.2% AT&T (TSBU) 32.2% Texas Instruments (DS&E) 106.8% Zyta 8.4% Eastman Chemical 18.5% Total Stock Value Standard & Poor 500 Stock value Source: US Dept. of Commerce Study 1995 £23016 (91.8% growth) £15911 (32.6% growth) THE NEW ISO 9000 2000 QUALITY STANDARD REASONS FOR CHANGE • ISO Technical Committee (TC) argue that: The main reason for the year 2000 revision is to give users the opportunity to add value to activities and to improve their performance continually by focusing on the major processes within the organisation ISO 9000 2000 CHANGES • CUSTOMER FOCUSED ORGANISATION • LEADERSHIP • INVOLVEMENT OF PEOPLE • PROCESS APPROACH • SYSTEM APPROACH TO MANAGEMENT • CONTINUAL IMPROVEMENT • FACTUAL APPROACH TO DECISION MAKING • MUTUALLY BENEFICIAL SUPPLIER RELATIONSHIPS IMPLEMENTATION PRINCIPLES • MANAGEMENT RESPONSIBILITY • RESOURCE MANAGEMENT • PRODUCT REALIZATION • MEASUREMENT, ANALYSIS AND IMPROVEMENT More clearly defined requirements • • • • • • • Continual improvement increased emphasis on the role of top management establishment of measurable objectives at relevant functions and levels Monitoring of information of customer satisfaction and/or dissatisfaction as a measurement of the system performance Increased attention to resource availability; determination of training effectiveness Measurement extending to the system, process, and product Analysis of collected data on the performance of the quality management system Quality is a Journey, not a Destination