Document

advertisement

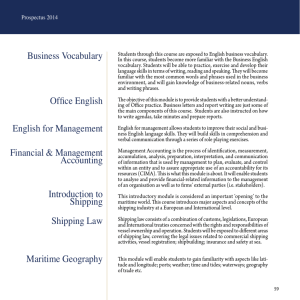

Sales and Distribution (SD) Overview SD FI Sales & Distribution Financial Accounting MM PP SM CO Materials Mgmt. Controlling Service Management AM R/3 Production Planning Fixed Assets Mgmt. EC Integrated Solution Quality Client / Server Management PM Plant Maintenance Open Systems Enterprise Controlling QM PS WF Project System Workflow HR IS Human Resources Industry Solutions SD • Mechanisms to execute the business processes used in the selling, shipping and billing of products and services • Tightly coupled data flow to the other SAP modules — Integration • Flexible and robust functionality that is tailored through configuration SD Components Master Data Sales Support Foreign Trade Sales Info System Sales Shipping Billing Transportation SD Overview — Master Data • Detailed information about customers, materials and business partners • Flexible data structures that support the business environment • Specialized master data to support sales order processing SD Overview — Sales Support • Provides the functionality to support the staff involved in business development and customer service processes • Primary functions – Sales Prospects – Contact Persons – Competitors and Competitive Products – Sales Activities – Direct Marketing SD Overview — Sales • Primary base for • • • • customer order management Highly customizable Sophisticated pricing Integrated ATP Integrated credit management • Sampling of functions – Inquiries & Quotes – Sales Orders – Returns – Contracts & Scheduling Agreements – Consignment – Rush Orders & Cash Sales – Back Orders & Subsequent Deliveries – Credit & Debit Memo Requests SD Overview — Shipping • Main functions – Picking, Packing & Inventory management – Generate Shipping Documents • Transportation Management – Routes – Transportation Scheduling • Delivery Scheduling, Returns Deliveries & Stock Transfer SD Overview — Billing • Invoice Generation — automatic or • • • • manual Comprehensive set of billing functions Linked documents — e.g. invoice & credit memo Real-time integration with finance (FI) Fully integrated and comprehensive pricing SD Overview — S I S • Flexible tool that allows one to collect, consolidate, and utilize data from sales and distribution processing • A component of the Logistic Information System (LIS) Transportation Foreign Trade Sales & Distribution - Process Flow - Supply Chain Process Customer Order Final Payment Picking Accounts Receivable Goods Issue Billing SAP Process Steps Sales Quotation Shipping Delivery Note Billing Billing FI A/R Post Incoming Payment Sales Order Picking Post Goods Issue Sales — Inquiry & Quotation • • • • • • Support pre-sales processes Are time sensitive Automatic availability check Automatic pricing No impact to FI Can be used as reference documents Sales — Sales Order • Core of customer order management • No impact to G/L • Can reference existing documents • Copies key information from master data • Automated standard functions ... – – – – – – – availability check MRP updating pricing credit check delivery scheduling export control shipping & route determination Shipping — Delivery Note • Initiates the shipping process • Control document for shipping processes — maintains status of each processing step • Re-confirms: availability, credit, foreign trade, delivery scheduling • Facilitates transportation planning Shipping — Picking & Packing • Picking: Physical activity of moving goods from the warehouse for further processing (packing, loading) • Packing: Determines packing materials and packing details • Advanced processing includes, e.g. batch mgmt., serial number control Shipping — Post Goods Issue • Completes the shipping process • Typically performed when customer takes ownership • Updates inventory • Updates G/L accounts – Cost of goods sold – Inventory Billing • Generate customer invoice • Updates FI – Customer account – G/L accounts: revenue, discount, etc. • Applies relevant pricing • Updates customer credit Sales & Distribution - Organizational Structures - Sales Organization Client 860 Pastime Corporation Company Code CC00 Domestic Sales Sales Organization So00 Europe Sales Organization EURO Asia Pacific Sales Organization APAC Wholesale Distribution Channel WH Direct Distribution Channel DI Wholesale Distribution Channel WH Retail Distribution Channel RE Wholesale Distribution Channel WH Baseball Division BB Baseball Division BB Baseball Division BB Baseball Division BB Softball Division SB Softball Division SB Softball Division SB Cricket Division SB Baseball Division BB Sales Organization • Sells and distributes products, negotiates terms of sales and is responsible for these business transactions • Critical organization element to the definition of business markets • A business transaction is linked to one Sales Organization Distribution Channel • Identifies how products and services reach the customer • Can be assigned to one or more Sales Organizations Division • Often times used to define product line distribution • Organization level to which customer specific information and requirements are maintained — e.g. pricing, partial delivery • Assigned to one or more Sales Organizations Sales Area • Organizational element comprised of: – Sales Organization – Distribution Channel – Division • Will be used to link together the organizational aspects of sales to customers • Used for statistical analysis Sales Area Domestic Sales Sales Organization SO00 Direct Distribution Channel DI Baseball Division BB Softball Division SB Wholesale Distribution Channel WH Baseball Division BB Softball Division SB Retail Distribution Channel RE Baseball Division BB Softball Division SB Sales Area Domestic Sales Sales Organization SO00 Direct Distribution Channel DI Baseball Division BB Softball Division SB Wholesale Distribution Channel WH Baseball Division BB Softball Division SB Retail Distribution Channel RE Baseball Division BB Softball Division SB Sales Office • Typically defines a territory or market area • Linked to one or more Sales Areas • Optional organization structure Internal Sales Organization Domestic Sales Area Western Sales Office Eastern Sales Office Sales Group • Sales Group – Sub-division of a sales office, territory or market Sales Person • Sales Person – Defined in HR — Personnel Admin. – Specifically defines an individual rather than a position (sales rep.) in sales processing Internal Sales Organization Domestic Sales Area Western Sales Office Southwest Sales Group Sales Person Sales Person Eastern Sales Office Northwest Sales Group Southeast Sales Group Northeast Sales Group Sales Person Sales Person Sales Person Shipping Point & Loading Point • Shipping Point – Location that performs all delivery related activities – Assigned a factory calendar – A delivery can be processed from only one shipping point • Loading Point – A subdivision of the shipping point used for more specialized handling Shipping Organization Sioux Falls PLANT PT00 Freight Dock Shipping Pt SP00 Dock #1 Loading Pt D1 Dock #2 Loading Pt D2 Express Shipping Pt QUIK Export Shipping Pt EXPT Dock #3 Loading Pt EX Dock #2 Loading Pt XP Sales & Distribution - Master Data - SD Master Data - Core Elements Master Data Pricing Material Master — Sales: sales org. 1 -General Data Basic Unit of Measure Division Material Group Sales Unit Delivering Plant Cash discount -Tax data Country Basic Data 1 - 2 Classification Sales: sales org. 1 - 2 Sales: general/plant Purchasing Foreign Trade: Import Data Sales: text Purchase order: text MRP 1 - 4 Forecasting Storage 1 - 2 Warehouse Management 1 - 2 Tax category Tax classification -Quantity stipulations Min. order quantity Min. delivery quantity Delivery unit Quality Management Accounting 1 - 2 Costing 1 - 2 Material Master — General Data Base Unit of Measure The Base Unit of Measure is the unit of measure in which stocks are managed within your company. Division You may enter the Division which your product is in for sales (defaults if entered in the Basic data screen). Material Group A (freely definable) key that’s used to group several materials or services for analysis/reporting as well as search by match code. Sales Unit This is the unit of measure in which the material is sold, if different from the base unit of measure. Delivering Plant Plant, from which the material is available for sale. This is a default value only. Cash discount Indicator used for materials, which allow for a cash discount. Material Master — Tax data & Quantity stipulations Tax data Country Country Tax category Taxes, applicable to this material (e.g. Federal, State taxes in US, VAT in GB) Tax classification taxable, exempt Quantity stipulations Min. order quantity Min. quantity a customer can order (in base unit of measure). Min. delivery quantity Min. delivery quantity to a customer. Delivery unit Only multiples of this number will be delivered to the customer. Material Master — Sales: sales org. Basic Data 1 - 2 Classification Sales: sales org. 1 - 2 -Grouping terms Sales: general/plant Purchasing Matl statistics group Material pricing grp Volume rebate group Acct assignment grp Commission group Item Category group Foreign Trade: Import Data Sales: text Purchase order: text MRP 1 - 4 Forecasting Storage 1 - 2 Warehouse Management 1 - 2 Quality Management Accounting 1 - 2 Costing 1 - 2 Material Master — Grouping terms Matl statistics group Helps to determine which data the system updates in the Logistics Information System (LIS). Material pricing grp A way to group materials with similar pricing conditions. Volume rebate groupA material can be assigned to a volume rebate group (e.g. Low Rebate, High Rebate) if the material qualifies for rebate. Acct assignment grp A grouping of materials with the same accounting requirements (used to determine revenue and sales deduction accounts) Commission group Several materials can be assigned to the same commission group, if the commission sharing between representatives is the same for these materials (e.g. Rep.A: 6%, Rep.B: 10%, Rep C: 12%). Item Category groupA grouping of materials, that helps the system determine the Item Category. Item Category determines how a specific item is processed by system. E.g. a text item is not relevant for pricing. Material Master — Sales: general/plant Basic Data 1 - 2 Classification General data Base unit Gross weight Net weight Avail. Check Sales: sales org. 1 - 2 Sales: general/plant Purchasing Foreign Trade: Import Data Sales text Purchase order: text Shipping data (times in days) Trans. Grp LoadingGrp Packaging material data Matl grp ship. matls MRP 1 - 4 Forecasting Storage 1 - 2 Warehouse Management 1 - 2 Quality Management Accounting 1 - 2 General plant parameters Negative stock Costing 1 - 2 Material Master — General data & Shipping data (times in days) General data Base unit The Base Unit of Measure is the unit of measure in which stocks are managed within your company. Gross weight In Base Units of Measure. Net weight In Base Units of Measure. Avail. Check Tells the system when to do an availability check, as well as which MRP elements (such as purchase orders, reservations) to include in the check. Shipping data (times in days) Trans. Grp Transportation groups are groups of materials that have the same transportation requirements. For example, all goods that need refrigeration. Loading Grp Loading groups define materials that have the same loading requirements, such as forklift truck, or crane. Material Master — Packaging material data & General plant parameters Packaging material data Matl grp ship. matls, or Material group shipping materials Freely definable group name, which is used to indicate groups of materials with similar shipping materials, such as liquids or bulk, for example. General plant parameters Negative stock Check mark indicator, which specifies whether negative stock is allowed at that plant. Material Master — Sales texts Basic Data 1 - 2 Classification Sales: sales org. 1 - 2 Sales: general/plant - Sales texts Text specific to the material and in an appropriate Purchasing Foreign Trade: Import Data Sales text Purchase order: text MRP 1 - 4 Forecasting language. Storage 1 - 2 Warehouse Management 1 - 2 Quality Management Accounting 1 - 2 Costing 1 - 2 Account Groups • Account group determines which fields are to be used in defining customer master data Field Status Field status controls the use of each field within the customer master determining whether a field is required, optional, suppressed or display only Field status controls are also relevant to a specific activity — create, change, or display Sales & Distribution - Customer Master - Customer Master General Data Sales & Distribution Data Company Code Data Customer Master • Centralized data for both SD & FI • Segmented into three sections – General data - address & communication – Company code data (FI) - banking and payment information related to FI – Sales data (SD) - pricing, delivery, output • The sales data is specific to one sales area and is therefore dependent on the sales organization Customer Master by Sales Area Customer • Sales Organization • Distribution Channel • Division Customer Master — Address & Communication General Data — Address Customer Name Search Term Street address, City, Postal code, Country Language General Data — Communication Telephone, Fax, Data numbers Customer Master — Control Data General data — Control data Account control : Vendor, Authorization Trading partner, Group key Tax information : Tax codes, Fiscal address Country code, City code VAT N, Tax jurisdiction code Equalization tax, Sole proprietor Tax on sls/pur. Reference data / area : Industry: International Locator No. Transport Zone Express station Train station Location code Customer Master — Marketing General Data — Marketing Classification : Nielsen ID Customer classification Industry Industry codes Operating figures : Annual sales Number of employees Fiscal year variant Sales prospecting : Legal status Customer Master — Payment Transactions General Data — Payment Transactions Bank details Country Bank Key Account holder Bank Account Control Key Collection Customer Master — Unloading Point General Data — Unloading points Unloading point Customer factory calendar Default Unloading Point Goods receiving hours Customer Master — Foreign Trade General Data — Foreign trade Country key for export control of customer Table of Denial Orders list (TDO) Special Designated Nationals list (SDN) Diversion High Risk Profile list (DHRP) Usage and Classification Customer Master — Contact Persons General Data — Contact persons Name Telephone number Department First name Form of address (e.g. Mr., Ms.) Function Customer Master — Accounting Information Company Code Data Accounting Information Accounting info Reconciliation Account Sort key Head office Interest calculation Interest indicator Interest calculation frequency Last key date Reference data Buying group Customer Master — Payment Transactions Company Code Data Payment Transactions Payment data: Payment terms Tolerance group Automatic Payment Transactions: Payment methods Alternative payer Lockbox Customer Master — Correspondence Company Code Data Correspondence Dunning data : Dunning procedure Dunning recipient Correspondence : Account number at customer Customer user Payment notices to : Customer Sales Accounting Legal Customer Master — Insurance Company Code Data Insurance Export credit insurance : Policy number Institution number Amount insured Valid until Lead months Deductible Customer Master — Sales Sales Data — Sales area Sales order : Sales district Sales office Sales group Order probability Item proposal Account at customer Pricing / Statistics: Price group Customer pricing procedure Price list type Customer statistical group Customer Master — Shipping S & D Data — Shipping Shipping : Delivery priority Shipping conditions Delivering plant Order combination Batch split allowed Partial Delivery: Complete delivery Partial delivery of item Maximum part deliveries Customer Master — Billing S&D Data — Billing Billing section : Manual invoice maint. Rebate Pricing Billing schedule Invoice list schedule Delivery and payment terms : Incoterms Payment terms Accounting : Account assignment group Taxes: Tax requirements for the customer Customer Master — Partner Functions S&D Data — Partner functions The different partners are assigned • • • • • SP BP PY SH … Sold-to-party Bill-to-party Payer Ship-to-party additional Partner function(s) Assigning Additional Partners — Siesta Baseball League - Vera Cruz, NM — Sold-to : 10018 Sold-to Bill-to : 10018 Payer : 10018 Bill-to Payer Ship-to Ship-to : 10018 — Siesta Baseball League - Vera Cruz, NM — Sold-to : 10018 Sold-to Bill-to : 10018 Payer : 10018 Payer Ship-to Ship-to : 10018 Bill-to Ship-to : 10249 - Bakersfield, CA Ship-to Sales & Distribution - Business Partners - Business Partners • Defines all of the parties involved in a business transaction and differentiates between their roles — customer, carrier, employees, customer contact, etc. • Through customizing the system automatically assigns partners to the customer master and to transactions Sold-to Ship-to Bill-to Payer Business Partners • The system creates these four business partners by default. All four are required. • All four may be the same or may be different. • Since these are automatically assigned partners you may need to add additional partners to carry out your business transactions. Sold-to Ship-to Bill-to Payer Business partners — Sold-to • Customer that orders the goods • Can perform all primary partner functions — sold-to, ship-to, payer, bill-to • Primary type of business partner • Cannot be linked to other sold-to partners Sold-to Ship-to Bill-to Payer Business partners — Ship-to • Party that receives the goods • Can be created as an independent partner and linked to one or more sold-to partners Sold-to Ship-to Bill-to Payer Business partners — Bill-to • Party that receives the invoice • Can be created as an independent partner and linked to one or more sold-to partners Sold-to Ship-to Bill-to Payer Business partners — Payer • Party that sends the payment • Can be created as an independent partner and linked to one or more sold-to partners Sold-to Ship-to Bill-to Payer Business Partners — Example Sold-to Sold-to Ship-to Bill-to Ship-to Ship-to Payer Ship-to Ship-to Ship-to Sales & Distribution - Pricing - Pricing • • • • “World-class” functionality Highly customizable & extendible One of the most complex features of SAP Used to determine the net price for a material or an order Pricing Process • Standard pricing calculates the gross price, then applies discounts, surcharges and applicable taxes to arrive at the final price final price = gross price - discounts + surcharges + taxes • Cost-plus pricing determines the base cost and applies the appropriate discounts, surcharges and taxes final price = cost - discounts + surcharges + taxes Pricing Components • Pricing is based on a matrix of predefined and custom elements • Delivered element groups (a.k.a. conditions) – Prices – Discounts & Surcharges – Freight – Taxes Pricing Procedure • In short, the mechanism used to arrive at the final price • Considers all of the applicable pricing conditions, e.g. material price, customer discount • Is assigned by: sales area, sold-to party and sales document type (e.g. sales order) Pricing Procedure • The pricing procedure uses what SAP calls “the condition technique”. • The pricing condition technique starts with the: – – – – – Pricing Procedure which looks at Conditions which use Access Sequences which accesses Condition tables which point to A price, discount or other condition ($) R/3 Pricing Process SALES DOC. ITEM DETERMINE PRICING PROCEDURE FOR ITEM DETERMINE ACCESS SEQUENCE FOR EVERY CONDITION TYPE IN PRICING PROCEDURE ACCESS THE CONDITION RECORDS AND DETERMINE PRICE PRICE THE ITEM SALES AREA & DOCUMENT TYPE & SOLD-TO CONDITION TYPE AND ACCESS SEQUENCE ARE LINKED IN TABLE CUSTOMER/MAT’L OR PRICE LIST/MAT’L OR MATERIAL --$9.25 N/A UNIFORM SALES DOC. SOLD PRICING AREA TYPE TO PROCEDURE KEY CONDITION TYPE ACCESS SEQUENCE PR00 KI00 TX00 FR00 US01 A 1 USSTD PR00 KI00 US01 B 1 USALT UK01 A 1 UKSTD TX00 FR00 UK02 A 1 UKSTD PRICING CONDITION CONDITION PROCEDURE TYPE USSTD PRICE ELEMENT CONTROL PARAMETERS UPPER/LOWER LIMITS USALT STOPS LOOKING AFTER FINDING FIRST VALUE LOOK FOR CONDITION ACCESS OR RECORDS IN THIS ORDER SEQUENCE DER OF CONDITION TABLES PR00 01 CUSTOMER/MATERIAL 02 PRICE LIST TYPE/MAT’L 03 MATERIAL 01 CUSTOMER/MATERIAL PR00 PRICE KI00 DISCOUNT TX00 TAXES 02 PRICE LIST TYPE/MAT’L FR00 FREIGHT 03 MATERIAL PR00 PRICE KI00 ETC. KI01 DISCOUNT ETC. Price Agreements • Simple price agreements – – – – product customer customer & material customer group & material • Detailed price agreements – pricing scales – rebates – customer expected price Specialized Master Data • Customer Material Info. Record • Item Proposal • Listing & Exclusion • Product Substitution Customer/Material Info. Record • Defines a customer alias for a material & description, for example: Material # : Glove Customer # : Pastime Glove • Can further define attributes of the material, shipping and partial delivery information specific to the product and customer • Referenced in the sales order using the Ordering Party overview Item Proposal • Used to define frequently ordered combinations or special assortments of products and quantities • Either products or products with quantities can be selected during order entry • An item proposal can be defined for a customer via the customer master record Material Listing & Exclusion • Used to control what products are available for a customer or group • Material Listing — defines products that can be sold to a customer • Material Exclusion — defines products that cannot be sold to a customer Product Substitution Material Determination • Enables automatic or manual substitution of materials during sales order processing • Examples: – substitute a standard product with a promotional material – substitute based on a customer preference – substitute based on selection list (manual) Customizing For Transactions Shipping Functions • Shipping Point Determination – The shipping point is determined for each line item based on the shipping point determination – shipping point = shipping condition + loading group + delivering plant Customizing For Transactions Shipping Functions • Route Definition – Route to be traveled and the transit time – Generic routes can be used to simply define transit time • Route Determination Proposed route = shipping point + destination country + transportation zone + shipping condition Sales & Distribution - Transactions - Business Document Types Returns Inquiry Quotation Sales Order Contract Consignment Scheduling Agreement Cash Sale Returnable Packaging Rush Order Debit Memo Credit Memo Order Processing Functionality • • • • • • • • Delivery scheduling Availability check Transfer of requirements to MRP Pricing Credit check Shipping point & route determination Foreign trade & license processing Document flow Delivery Scheduling • Automatic scheduling of essential shipping activities ... Calculated using defined activity times ... Resulting in scheduled activity dates • Determined using backward and forward scheduling rules Delivery Scheduling • Structure of sales documents Header Line item # 1 Schedule line # 1 Schedule line # 2 Line Item # 2 Schedule line # 1 Delivery Scheduling — Terminology • Transportation lead time — time required to schedule transportation • Pick/Pack time — time required for picking and packing • Load time — time required to load • Transit time — time required to transport goods from shipping point to ship-to Backward Scheduling 25 Order Date 25th Material Availability 26th Transp. Sched. Loading 27th Goods Issue 28th Transp. Sched. Time (1 day) Pick & Pack Time (2 days) Requested Delv. Date 29th 31st Loading Time Transit Time (1 day) (2 days) Forward Scheduling 27 Material Availability 26th Order Date 27th Transp. Sched. 27th Goods Issue 29th Loading 28th Transp. Sched. Time Loading Time Transit Time (1 day) (2 days) (1 day) Pick & Pack Time (2 days) Requested Delv. Date 31st 1 New Delv. Date Availability Check • Determines the material availability date • Considers inward and outward movement of inventory — customizable • Influences partial deliveries by – proposing a quantity that can be delivered on the requested date (complete delivery) – determines the earliest date for full delivery – determines the number and dates for partial deliveries to fulfill the order Availability Check • In determining the material availability date the system can include specific stocks if selected, such as: – Safety stock – Stock in transfer – Quality inspection stock – Blocked stock – Restricted use stock Transfer of Requirements to MRP • Ordered quantities are passed to MRP (MM) • Controlled by the schedule line category • Blocking of documents can affect requirements passing — delivery block Credit Check • Efficient means to implement credit management • Integrated with FI — via credit control area • Automatically alerts when a credit check fails • Comprehensive credit management reporting Shipping Point & Route Determination • A shipping point is determined for each line item — shipping point determination • A delivery can only be processed from one shipping point • Routes - route to be traveled & transit time are determined using customized rules • Routes can be used to simply define transit time Foreign Trade & License Processing • Predefined trade areas — NAFTA, EU • Automated reporting for trade areas • Automated controls – license management – embargo lists – control by customer, country, product, point in time Shipping Shipping Overview • Comprehensive functionality to support picking, packing and loading functions • Work list and deadline monitoring • Functions with backorder processing • Tightly coupled to the MM and FI modules • Facility for transportation management Shipping Overview Order Order Order Order Delivery Delivery Delivery Order Combination Order Delivery Delivery Partial Delivery Complete Delivery Shipping Overview • Delivery creation activities – checks order and materials to determine if a delivery is possible — delivery block, incompleteness – confirms availability – confirms export/foreign trade requirements – determines total weight & volume Shipping Overview • Delivery creation activities – generates packing proposal – considers partial deliveries – updates route assignment – assigns picking location – determines batches – updates sales order — status, delivery qty Deliveries & Delivery Notes • The Delivery Note – Initiates the delivery process – Control mechanism for the process – Changes to delivery are allowable - products, quantities Picking Delivery Note Packing Status Loading Post Goods Issue Delivery Due List • • • • Produces a work-list of deliveries Encompasses deliveries and transfers Can be scheduled to run in batch Automatically combines deliveries Picking • • • • Quantities based on delivery Assigned date when picking should begin Automated storage location assignment Supports serial number tracking and batch management • Integrated with Warehouse Management (WM) Packing • Identifies which packaging is to be used for specified products • Identifies and updates accounts associated with returnable packaging • Tracks the packed product by container • Insures weight/volume restrictions are enforced Goods Issue • Event that indicates the change in ownership of the products • Reduces inventory • Automatically updates the G/L accounts • Ends the shipping process and prevents changes to the shipping documents Goods Issue Inventory General ledger 750 Cost of goods sold 750 Billing Overview • Automated invoicing based on sales orders and/or deliveries • Functionality for processing credit/debit memos and rebates • Integration with FI & CO-PA • Updates customer’s credit data • Can create pro forma invoices Automatic Account Assignment • Defines the G/L accounts that billing entries are posted to — revenue, deduction, freight charges Application Condition Chart of Type Accounts V From Sales Doc. Sales Org. Cust Acct. Grp. Account G/L Key Account KOFI CHRT SOxx 01 ERL 610000 From Table From Sales Doc. From Sales Doc. From Customer Master From Pricing Proc From Table Billing Methods Separate invoice per delivery Order Delivery Invoice Delivery Invoice Delivery Collective Invoice Order Order Invoice Split Order Delivery Invoice Delivery Delivery Invoice Invoice Billing Documents • Explicitly specify documents • Billing due list — builds a worklist of invoices that should be generated • Automatic posting to FI Billing Documents General ledger Revenue 2000 Customer 2000 A/R recon. 2000 Billing Plans • Periodic — total amount for a planned billing period • Milestone — distributing the total amount over multiple billing dates - typically used with the project system (PS) • Installment — evenly proportioned amounts and defined payment dates • Resource related — consumed resources such as service or consulting SD Milestone Billing Sales Order Billing Plan Sold-to : QAZ Industries Material : 546-dk1 Generator Billing date 11/20/96 01/20/97 04/20/97 05/20/97 06/20/97 Delivery Date : 06/20/97 Price : $300,000 Description % Value Contract Assembly Operational Acceptance Final invoice 10 40 40 10 -- 30,000 120,000 120,000 30,000 -- Billing Milestone block x x x x x x x Billing status x x Outline Agreements • Contracts • Schedule Agreements Contracts • Defined quantities and validity period for a customer • The contract is fulfilled by orders placed against the contract - release orders • Contracts are automatically updated through release order processing • Pricing can be assigned to a contract Contracts Contract Target Qty: 900 Order Qty: 700 .. . Contract Target Qty: 900 Order Qty: 750 Release Order Order Qty: 200 Release Order Order Qty: 150 Scheduling Agreements • Defines specific product quantities and delivery dates for a customer • Schedule lines and processed through standard delivery processing • Availability check is performed during creation and quantities are passed to MRP • System automatically updates delivered quantities Scheduling Agreements Scheduling Agreement Date 05/15 06/15 07/15 08/15 Qty 100 100 200 300 Delivery 5/10 100 Delivery 6/10 100 Delivery 7/10 200 Delivery 8/10 300 Backorders Backorder Processing Rescheduling Backorders • Backorder processing – determines which orders have unconfirmed quantities by customer or material – sort the orders according to priority – assign available stock to outstanding orders or reassign confirmed quantities to highprofile orders Backorders • Rescheduling – updates the orders with the results of the availability check – can be used to manage the distribution of available inventory when demand is greater than supply • Best if run in batch mode, rescheduling can be very time consuming Customer Returns Return Order Goods Receipt Quality Inspection Credit Memo Customer Returns 1 2 3 Order Return Delivery Invoice Returns Delivery Return to Inventory Credit Memo Customer Returns • Returns document – Billing block can be proposed – Use the Order reason field to identify the reason for the return – Full access to pricing and ability to re-price • Return delivery – Issues a goods receipt to place material into inventory Customer Returns • Credit memo – Billing block must be cleared from Return – Posts to FI – Can be processed in batch (background) – Can be processed collectively (grouped) Output & Text Communication — Output Bar Coded Documents Printed Documents FAX SAP Document Email EDI Workflow Communication — Output • Output — traditional forms or electronic communications produced for internal or external partners • Assigned to business partners & sales documents • Definable media — EDI, fax, print • Highly customizable — Sapscript Communication — Text • Texts are used for internal and external communication • Created for business partners, materials, header or item level of sales documents — order, delivery, billing, picking lists SIS Overview • Flexible information system designed to support business planning, forecasting and reporting • Pre-defined catalog of performance measures and reports • On-demand access to reports and exceptions • Data maintained in a separate database Logistics Information System • • • • • • Inventory Management Purchasing Sales and Distribution Production Plant Maintenance Quality Management Inventory Information System Standard Analysis • • • • • Material Plant Storage Location MRP Controller Material Groupings Purchasing Information System Standard Analysis • • • • • Material Vendor Material Group Purchasing Group Purchasing Documents Sales Information System Standard Analysis • 5 Pre-defined drill-down reports – Customer – Material – Sales Organization – Shipping Point – SD Documents Production Information System Standard Analysis • • • • Product Group Material Work Center Production Resources and Tools Reporting Tools • • • • • • Value display - absolute or percentage Top N - top 10, top 100, etc. Sorted - ascending or descending ABC Classification Graphics - 2D, 3D