Self-Optimizing Control of the HDA Process

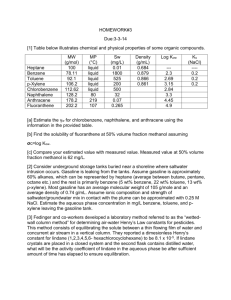

advertisement

Self-Optimizing Control of the HDA Process • Outline of the presentation – – – – Process description. Self-optimizing control procedure. Self-optimizing control of the HDA process. Concluding remarks. Process Description • Benzene production from thermal-dealkalination of toluene (hightemperature, non-catalytic process). • Main reaction: Toluene + H2 → Benzene + CH4 • Side reaction: 2·Benzene ↔ Diphenyl + H2 • Excess of hydrogen is needed to repress the side reaction and coke formation. • References for HDA process: – McKetta (1977) – first reference on the process; – Douglas (1988) – design of the process; – Wolff (1994) – discuss the operability of the process. • No reference about the optimization of the process for control purposes. Process Description Purge (H2 + CH4) Compressor H2 + CH4 Toluene Mixer FEHE Furnace PFR Quench Separator Toluene Benzene Toluene Column Diphenyl Cooler CH4 Benzene Column Stabilizer Self-Optimizing Control Procedure • Objective: Optimize operation – Find the optimum. – Implement the optimum (in practice). • Self-optimizing control: – Set point control which optimize the operation with acceptable loss. Loss = J – Jopt • Pure steady state considerations. • Stepwise procedure for evaluating the loss: – – – – – – – Degree of freedom analysis; Cost function and constraints; Identification of the most important disturbances (uncertainty); Optimization; Identification of candidate controlled variables; Evaluation of loss; Further analysis and selection. Self-Optimizing Control of the HDA Process Steady-state degrees of freedom 10 9 4 1 2 7 3 17 6 5 16 14 12 15 13 11 8 Self-Optimizing Control of the HDA Process Cost Function and Constraints • • The following profit is maximized (Douglas’s EP): (-J) = pbenDben – ptolFtol – pgasFgas – pfuelQfuel – pcwQcw – ppowerWpower - psteamQsteam + Σ(pv,iFv,i), i = 1,…,nc. Where: – Qcw = Qcw,cooler + Qcw,stab + Qcw,ben + Qcw,tol; – Qsteam = Qsteam,stab + Qsteam,ben + Qsteam,tol; – Fv,i = Fpurge + Dstab,i + Btol,i, i = 1,…,nc. • Constraints during operation: – – – – – – – – – • Production rate: Hydrogen excess in reactor inlet: Bound on toluene feed rate: Reactor pressure: Reactor outlet temperature: Quench outlet temperature: Product purity: Separator inlet temperature: + some distillation recovery constraints Manipulated variables are bounded. Dben ≥ 265 lbmol/h. FH2 / (Fben + Ftol + Fdiph) ≥ 5. Ftol ≤ 300 lbmol/h. Preactor ≤ 500 psia. Treactor ≤ 1300 °F. Tquencher ≤ 1150 °F. xDben ≥ 0.9997. 95 °F ≤ Tflash ≤ 105 °F. Self-Optimizing Control of the HDA Process Identification of the Most Important Disturbances Disturbance Nominal Lower Upper 1 - Gas feed temperature 100 80 112 2 - Toluene feed temperature 100 80 120 3 - Gas feed composition 0.95 0.90 1.00 4 - Benzene price 9.04 8.34 9.74 5 - Toluene recycle temperature 212 202 230 6 - Relative volatility boil-up stabilizer 36 32.4 39.6 7 - Relative volatility boil-up benzene column 2.67 2.41 2.94 8 - Relative volatility boil-up toluene column 10 9 11 9 - Upper bound on toluene feed flow rate 300 285 315 as fe e G To as d lu fe tem To en ed p lu e fe tem era N en e tu om e d t per re in f e a a G eed mp tu - lo l r as te er e - we f G ee m atu up r as d pe r p fe co rat e - er ed m ur lo co po e - we To m sit up r lu B po ion p e en s To ene iti - l r z lu r o o B e en ec en ne n we e yc ze pr - u r r p l R ec e t ne ice pe el yc em p ri - lo r . V le R p el Re o e ce w . V l. l. tem ra - er b tu u R el ol. Vo oil per re pp -u a . V bo l . - er ol il- bo p s tur low i R . el bo up l-u tab e - er . b p i u i R Vo l-u en st lize pp a el l. e p . V bo b zen bil r - r B ol il- enz e c ize low ou . b u p en olu r - u er o n B d il- to e c m p ou o u lu o n p nd n t p t en lum - l er ow o o e on lu lu n c e e o e to ne ne lu - up r m lu en fee col n - per e d f um lo fe lo n w ed w - er flo rat up w e - pe ra lo r te w - u er pp er G Profit (M$/year) Self-Optimizing Control of the HDA Process Optimization 6,5 6 5,5 5 4,5 4 3,5 3 2,5 2 Self-Optimizing Control of the HDA Process Optimization • • Active constraint control: – (1) Benzene product purity (lower bound); – (2) Recovery (benzene in feed/benzene in top) in stabilizer (lower bound); – (3) Loss (toluene in feed/toluene in bottom) in benzene column (upper bound); – (4) Loss (toluene in feed/toluene in top) in toluene column (upper bound); – (5) Toluene feed flow rate (upper bound); – (6) Separator inlet temperature (lower bound); – (7) Inlet hydrogen to aromatic ratio (lower bound); – (8) By-pass feed effluent heat exchanger (lower bound). 9 remaining unconstrained degrees of freedom. 8 5 7 1 6 4 3 2 Self-Optimizing Control of the HDA Process Identification of Candidate Controlled Variables • Candidate controlled variables: – – – – – – Pressure differences; Temperatures; Compositions; Heat duties; Flow rates; Combinations thereof. • 137 candidate controlled variables can be selected. • 17 degrees of freedom. • Number of different sets of controlled variables: 137 137! 21 = =2.1×10 17 17!120! • 8 active constraints (active constraint control). • What to do with the remaining 9 degrees of freedom? – Self-optimizing control implementation!!! Analysis of linear steady-state model from 9 u’s to 137 candidate outputs • Scale variables properly! • G: matrix with 9 inputs and 137 outputs – (Glarge)=5 • Select one output at the time: – Select output corresponding to largest singular value (essentially largest row sum) – “Control” this output by pairing it with an input (which does not matter for this analysis), and obtain new matrix with one input (and output) less – Final result: (G9x9)=2.5 which is OK (“close” to 5) – Method is not optimal but works well Self-Optimizing Control of the HDA Process Further Analysis and Selection • Minimum singular value analysis of G gives that we should control (i.e. keep constant) – (9) Hydrogen in reactor outlet flow; – (10) Methane in reactor outlet flow; – (11) Reboiler duty in benzene column; – (12) Condenser duty in toluene column; – (13) Compressor power; – (14) Separator feed valve opening; – (15) Separator vapor outlet valve opening; – (16) Separator liquid outlet valve opening; – (17) Purge valve opening. 13 17 8 9 5 10 15 7 1 16 6 12 14 3 4 11 2 Self-Optimizing Control of the HDA Process Concluding Remarks • Demonstration of a self-optimizing procedure. • The economy in the HDA process is rather insensitive to disturbance in the process variables. • A set of controlled variables is found from an SVD screening of the scaled linearized model.