XU Wenying, Vice President of China Rubber Industry Association

advertisement

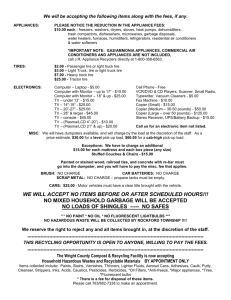

Development and Prospect of China's Tire Industry Secretary-General of China Rubber Industry Association, Xu WenYing China Shanghai May 28, 2015 Status of China’s tire industry - the overall situation China currently has more than 500 large and medium tire business, among which 300 enterprises producing car tire passed 3C certification In 2014, tire production quantity in China is 0.562billion pieces, with an year on year increase of 6.2%. From 2001 to 2005, the average annual growth rate of tire production was 12.1%; from 2006 to 2010, it was 9.2% and from 2010 to 2015, 4.6%. Since 2005, China has been the largest country in the world for tire production. There are 29 tire companies in mainland China ranked top 75 of the world’s tire enterprises. Status of tire industry in China - the world’s largest producer 2001 2014 Increase% China 0.141billion pieces 0.562billion pcs 299% America 0.246billion pcs 0.162billion pcs -34% Japan 0.162billion pcs 0.16billion pcs -1% Surpassed America in 2005 Surpassed America +Japan in 2008 Status of tire industry in China - the world’s largest producer 1,The exports amount of China’s car tire in 2007 is 6.41 billion US$, which was larger than Japan’s amount of 6.094 billion US$ and made China become the world’s largest tire producer. 2,The car tire export volume of China in 2014 was 14.5 billion with an increase of 125% compared with the amount in 2007. 3, In recent 5 years, the annual exports amount accounts for around 40% of the national output and a half of the total world’s tire trade volume, which makes China become the world’s major tire supplier. Status of China’s tire industry in 2014 In 2014, the overall situation of China's tire industry features increasing production with decreasing sales revenue, growing export volume with falling export value, high inventories, low margins, insufficient capacity utilization, and slowing pace in capacity. In 2014, the national tire production is 562 million pcs with a y-o-y (same as below) increase of 6.2; among which, the radial tire production is 511 million with an increase of 7.3%, making up 90% of total production; bias tire is 51 million pcs, down by 3.7%. Among radial tire, steel tire production is 112 million pcs, which was increased by 4.6%; and the semi-steel tire is 399 million, up by 8.1%. The status of main tire member in January-March of 2015 20 15.38 4.98 3.34 0 -20 -0.76 现价工业产值 -14.02 销售收入 -7.09 综合外胎产量 -15.32 出口交货值 利润 -17.17 -40 2014年一季度增幅% 9.25 2015年一季度增幅% -37.06 Imports of New pneumatic rubber tire in JanuaryMarch of 2015 401110 Quantity (kg) Amount (US$) Price (US$/kg) Year on year % of Quantity Year on year % of Amount Jan 5,144,471 39,547,354 7.69 -19.1 -19.8 Feb 4,862,134 36,553,727 7.52 7.9 5 Mar 7,013,864 50,990,997 7.27 -18.3 -19.7 From January to March, 401110 imports fell 12.5% compared with last year, and the price of 7.47US $ / kg Quantity (kg) Amount (US$) Price (US$/kg) Year on year % of Quanti ty Jan 536,765 3,298,641 6.15 -47.4 -60.1 Feb 533,525 3,177,627 5.96 -28.5 -16.4 Mar 687,360 4,357,387 6.34 -42.6 -41.9 401120 Year on year % of Amoun t From January to March, 401120 imports fell 40.7% compared with last year, and the price 6.16 of US$/kg Exports of New pneumatic rubber tire in JanuaryMarch of 2015 401110 Quantity (kg) Amount (US$) Price (US$/kg) Year on year % of Quantity Year on year % of Amount 1 137,433,237 421,850,423 3.07 -13.1 -21.6 2 109,104,496 324,771,680 2.98 14.4 -1.3 3 113,877,043 335,592,468 2.95 -24.3 -33.1 From January to March, 401110 exports fell 10.8% compared with last year, and the price of 3US$/kg 401120 Quantity (kg) Amount (US$) Price (US$/kg) Year on year % of Quantity Year on year % of Amount 1 241,329,537 598,329,904 2.48 -1.9 -15.3 2 189,756,763 467,735,703 2.46 29.1 8.8 3 202,543,857 498,215,248 2.46 -19.8 -30.4 From January to March, 401120 exports fell 1.8% compared with last year, and the price of 2.47 US$/kg Status of the tire industry in China-the achievements Firstly, the rapid expansion of industrial scale Secondly, the rapid adjustment of product structure Thirdly, the simultaneous development of both markets Fourthly, thanks to new advances in manufacturing technology , manufacturing of tire production equipment is basically localized and has reached a certain technology level, and a number of multinational companies have started to choose equipment made in China. Fifthly, the increasingly diversified capital structure The co-existence of state-owned, foreign-funded, private and other forms of businesses have promoted the industry development in various extents Status of the tire industry in China-the achievements The volume of tire production, exports and the number of enterprises in China all ranks first in the world, and it has relatively completed tire industrial system. Except the natural rubber primarily depending on imports, the raw materials of the tire industry including synthetic rubber, carbon black and zinc oxide and other additives can be provided by numerous factories in China. And for the steel frame materials such as steel wire, the internal mixer, rolling machines, the molding machines and vulcanizing machines and other rubber machines, the capability of our domestic manufacturers is quite impressive as well. Tire industrial system Rubber material Carbon black and other additives steel wire and other frame material s Rubber machine s Status of the tire industry in China-Gap with international advanced level From the global perspective, China’s tire industry can be regarded as large while not strong, the market image of overall brand is low-end with low degree of internationalization, no world-class brands, low technology content, severe product homogeneity as well as low-level redundant construction, industrial concentration not high, low resource utilization, and excessive consumption of social resources. P r i c e i n d e x Three giants Affiliated brands of these three giants , Continental , Pirelli and other brands Korean enterprises Chinese enterprises Reputation among customers Status of the tire industry in China- Actual Problems 1. Insufficient capacity utilization 2. Low average industry profit margin, only about -4%, far lower than the 15% profit margin of the well-known brands. 3. Lack of R & D investment, insufficient innovation 4. Relatively serious product homogeneity 5. Sales channels lack of innovation 6. Natural rubber heavily dependent on imports while tires depending on exports 7. Primarily replacement tires and small proportion of original tires Status of China’s tire industry-reasons for the current problems Firstly, gap in terms of products Secondly, gap in terms of brand level. Thirdly, gap in terms of development mode Fourthly, gap in terms of industrial quality system Fifthly, gap in terms of innovation capability Sixthly, gap in terms of industrial concentration. Seventhly, gap in terms of circular economy model. Eighthly, gap in terms of technical regulations and standards. Ninthly, gap in terms of business philosophy. The main challenge of tire industry in China 1,the conflict of product’s structural surplus is tremendous, and redundant construction at low levels has not been fundamentally prevented. According to the incomplete statistics, China has newly added the production capacity of 15 million steel tires and 100 million semi-steel tire in 2013, and 15 million steel tires as well as 150 million semi-steel tire in 2014; the product homogeneity and business convergence becomes more severe with scarcity of high-end products, surplus of low-end products, technology products with low added value, disorderly industry competition as well as significant drop of sales revenue, which dramatically influence the sustainable development of enterprises. The primary challenges of tire industry in China 2, Low tire industry concentration, and lacking of international competitiveness. Taking the world’s top 75 enterprises in tire industry in 2014 as the example, the sales revenue of these companies is of &179.5 billion total, and four enterprises’ sales revenue is more than $10 billion, that is Bridgestone, Michelin, Goodyear, Continental respectively. And the sales revenue of these four companies is about $81.7 billion, accounting for 46% of the total 75 companies ‘ sales revenue. And the top 10 Chinese tire companies are listed as follows, Zhongce, Triangle, Linglong, Double coin, Hengfeng, Xing Yuen, AEOLUS,Jinyu, Shengtai and Guilun; and their total sales revenue is $18.8 billion, accounting for 10% of the total 75 companies’ sales revenue, which is only $1.2 billion more than Goodyear’s,the company ranking the third,$17.6 billion and far lower than Bridgestone’s and Michelin’s, $ 27.4billion and $25.5 billion, ranking the first and second respectively. 。 The primary challenges of tire industry in China 3,Weak innovation capability of the enterprises, lacking of brand value. Taking tires with the same specification as example, the Michelin tire’s price, due to its brand influence in the market, normally is 20% higher than the average tire price in the market. 4, There is more and more trade friction, which affects the export and production of the enterprises. 5, Standard adjustment of the composite rubber and increase of the import tariffs of the natural rubber severely affects the development of Chinese tire industry. The opportunities of Chinese tire industry 1,The automobile industry offers tremendous demand power for the development of the tire industry Year Total 2015 ownership (10000 pcs) Car ownership (10000 pcs ) Commercial vehicles’ ownership (10000 pcs) Average ownership of every 1000 people (10000 pcs) 15356 11340 4016 118 2016 17418 13003 4415 134 2017 19509 14715 4794 150 2018 21633 16479 5154 166 2019 23794 18303 5491 183 2020 25996 20192 5804 200 In accordance with the data of 812 for average ownership of every 1000 people in America, 634 in Germany,and 589 in Japan, China's auto industry and the tire industry at least preserves 10-15 years of golden development under the conservative estimate. The opportunities of Chinese tire industry 2,The introduction of ‘Proposals on tire industry’ will curb the blind development of the tire industry On September 17, 2014, the MIIT released the ‘Proposals on tire industry’ and further highlighted the rigid quotas including green, environmental protection, energy conservation, energy requirements to encourage the enterprises to upgrade and optimize on aspects including product performance, production processes, reduce energy and resource consumption and eliminate backward production capacity. The effective implement of these policies will play an active role in guiding and promoting to eliminate backward production capacity, regulate the market and upgrade the industry. The opportunities of Chinese tire industry 3,’ Green Tire Technology Specification’ and other industry self-regulatory rules will enhance the technological level of China's tire industry The ‘Green Tire Technology Specification’ developed by China Rubber Industry Association had been officially implemented in the industry on March 1, 2014, which is China’s first green tire industry self-regulation standard. Its release laid solid foundation for China’s next move on tire labeling. Developing green tires and promoting the industrialization process of the green tire is the most important direction of realizing the adjustment of product structure and corporate restructuring and upgrading. China Rubber Industry Association had also set up the "green tire industry work promotion commission“ as well as a "green tire technology service center" to implement the service on promoting the green tire industry technology and technical standards of green tire labeling system as well as grading procedures and other works. These efforts will accelerate the technological progress and upgrading of Chinese tire products. The opportunities of Chinese tire industry 4, The construction of tire test site has made substantial progress, which provides a test basis for the development of the tire industry Tire testing site is not only an important testing means on application of new technologies and new product development, but also one of the important symbol reflecting national production level and tire development level. Without tire test site, the outdoor test means is not complete, thus many underlying data on tire applications are not available; on the one hand it is difficult to enter the automobile accessory market, on the other hand, it is very negative for export (especially the EU) as well. At present, with the smooth construction of Central Asia and Yancheng automobile tire test site (tires), it is expected to be used before the end of 2015, which will provide test basis for the new product research and development. 5、The implementation of “one belt and one road" and "Made in China 2025" and other policies. 2015 Tire Industry Forecast In 2015, the national tire production is 0.587 billion pcs with an increase of 4.2%; and among which, the radial tire production is 0.534 billion with an increase of 4.6%, and the rate of the radial tires is 91%; bias tire is 51 million pcs, which will be increased by 3.9%. For the radial tire, steel tire production is 116 million pcs, with an increase of 3.6%; and the semi-steel tire is 418 million, with an increase of 4.8%. Future demand forecast on Chinese radial tire Year Car radial tire(10000 pcs) Truck radial tire(10000 pcs) Total(10,000 pcs) 2016 41879 12312 54191 2017 43814 12811 56625 2018 45838 13476 59314 2019 47956 14098 62054 2020 50172 14749 64921 Thanks!