dimethyl carbonate - Kowa American Corporation

advertisement

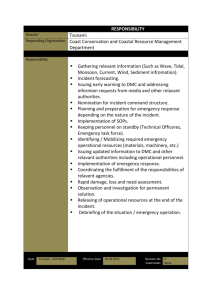

DIMETHYL CARBONATE (DMC) The Newest VOC Exempt Solvent Kowa American Corp October 2011 Previous VOC Exempt Coating Solvents • Realistically there were only a handful of VOC exempt solvents that are not HAPS (or ODS) and under $ 2.00/lb that formulators can use for coating, cleaning & adhesive solvents: • Acetone • Methyl acetate (MeAc) • tert-Butyl Acetate (tBAc) • p-Chlorobenzotrifluoride (PCBTF) Dimethyl Carbonate (DMC) • VOC exemption petition filed July 2004 by Kowa American Corp. • DMC has perhaps lowest MIR value of any liquid chemical in commercial use based on studies conducted by Dr. William Carter (study funded by Exxon Mobil Chemical) • Ultra-low MIR is allowing for fast approvals by the various states due to its very favorable ozone reduction potential DMC & PC recently exempted by the EPA • Dimethyl Carbonate (DMC) & Propylene Carbonate exempted by EPA on Jan 13, 2009 • Each state must also exempt DMC & PC for stationary source VOC rules. • Almost all states beside California will have exempted DMC by mid 2012 (45 states have now exempted DMC (Oct. 2011)). • California must have each of their Air Districts separately exempt DMC for coatings, Inks and adhesives, which is proceeding forward. DMC for Architectural, Aerosol & Automotive Refinish Coatings • DMC is VOC exempt in all states today except for Mass. & parts of California for: Architectural Coatings (subpart D), Automotive Refinish Coatings (Subpart B) and Consumer Items (subpart C) based on Federal VOC rules (40 CFR part 59) • DMC (with its ultra low MIR value) can be used in aerosol coatings in Calif. (soon to be approved for all of USA for aerosol coatings). DMC VOC Exempt States Washington March 2011 Montana Oregon May 2010 Vermont New Hampshire Wisconsin August 2010 South Dakota June 2010 Nebraska June 2010 Utah March 2010 California Each AMD must exempt New Mexico Kansas Sept. 2010 Oklahoma July 2010 Indiana Texas April 1, 2010 New Jersey Ohio West Virginia Virginia Delaware Maryland Kentucky Tennessee August 2010 North Carolina Arkansas Alabama March 2010 Alaska Dec. 2010 Massachusetts Rhode Island Sept. 2010 Connecticut Pennsylvania Iowa Missouri Dec. 2010 New York Dec 2010 Michigan Illinois Colorado Arizona Maine Minnesota Idaho March 2010 Wyoming Oct. 2010 Nevada North Dakota South Carolina Nov. 2010 Georgia Louisiana Florida Hawaii Green states are VOC Exempt DMC Exemption Status in Calif. • San Diego, Santa Barbara, Monterey Bay, Mohave, Butte ,Ventura, Colusa, Antelope Valley & Feather River AMD’s have exempted DMC as a VOC with no restrictions on use. • There are no VOC rules in most northern and mountain AMD’s (DMC functionally exempt) • Shasta, Glenn, El Dorado, Tehema & San Luis Obispo AMD’s may require a variance for some stationary sources, most architectural uses do not have VOC rules. • Santa Barbara users must file for a permit DMC Exemption Status in Calif. • Bay Area AQMD (San Francisco area) is drafting a rule exempting DMC for late 2011 public comment, early 2012 exemption • SCAQMD (L.A. area) has proposed DMC as VOC exempt in coating of metal parts according their rule 1107, individual permits would be required, early 2012 target date, other uses to be examined after this approval. • San Joaquin Valley, Imperial and Sacramento AMD’s expect to exempt by end of 2011 Del Norte Siskiyou Shasta Trinity Green = DMC VOC Exempt or Functionally Exempt/ no VOC rules (no restrictions on use of DMC) Modoc Lassen Tehama Butte Glenn Light Green = permit or an individual variance may be needed Plumas Sierra Nevada Colusa Lake El Dorado Yolo Alpine Napa Amador Sonoma Solano Marin San Contra Joaquin Tuolumne Costa San Francisco Light Blue = In rulemaking or preparing rule or partial rule Tan = no formal rulemaking yet Mono Alameda San Mateo Santa Santa Clara Merced Cruz San Benito Fresno Inyo Tulare Monterey Kings San Luis Obispo Kern San Bernardino Santa Barbara Los Ventura Angeles Orange Riverside San Diego Imperial California CARB Consumer items • CARB regulates “consumer product” applications (coatings are covered by each AQMD separately) • Paint thinners is in their “multi-purpose solvent” classification (some local Calif. AMD’s debate that CARB can regulate paint thinners over them) • CARB needs typical formulations for non-coating consumer applications using DMC, including the solvent the DMC will replace for CARB to do a health hazard assessment. CARB Contact: Carla Takemoto 916-324-8028, ctakemoto@arb.ca.gov MIR Reactivity Values (2009) MIR gram basis MIR mole basis DMC 0.055 4.95 Ethane 0.26 7.8 Acetone 0.35 20.3 Methyl Acetate 0.067 5.2 Prop Carbonate 0.27 27.56 Benzotrifluoride 0.28 40.91 DMC General Properties • DMC is a colorless, fast evaporating solvent • Has substantial polar nature, and moderate hbonding strength effective in replacing esters, glycol ethers and ketones in formulations • Has low toxicity, an unobjectionable methanol type odor and low skin irritation • Freezes at 2 – 4 ºC (36 –38 ºF) • Flammable Liquid, Flash point 17 ºC (63 ºF) DMC Structure O CH 3 O C O CH 3 DMC Evaporation Rate Fast to moderate evaporation rate (3.22 – 3.4, BuAC = 1.0), similar to tBAC (2.8), toluene (2.0) and isopropyl acetate (3.0) Can be used to as slightly slower evaporating replacement for MEK (3.8), Ethyl Acetate (4.1- 4.2), or as faster evaporating replacement for IPA (1.7), MPK (2.3), Ethanol (1.8) and MIBK (1.6) DMC - Flammability • DMC has a flashpoint of 63ºF (17ºC) • Flammability will limit use in consumer coatings, cleaning or indoor applications • Flammability risk still much lower than acetone (-4º F), ethyl acetate (26ºF) or MEK (26ºF), which DMC can readily replace • Partially water soluble (up to 13 % in water), which allows water to be more effective in fighting DMC based fires. Flashpoint, E. rate, Boiling point Evaporation Flashpoint Rate ºF BuAc =1.0 Boiling point ºC DMC 3.22 63 90 PCBTF .9 109* 139 Acetone 5.6 -4 56.5 <.005 269.6 240 Prop Carb tBAc 2.8 40 98 BTF 2.8 54 102 DMC Solubility Properties • Hildebrand solubility parameter 20.3 Mpa • Hansen solubility parameters: Dispersion 15.5 polar 3.9 h-bond 9.7 molar vol. 84.2 • Similar solubility parameters to some common glycol ethers: cellosolve acetate, ethylene glycol butyl ether acetate, propylene glycol monobutyl ether and propylene glycol monoethyl ether acetate DMC Solubility Properties DMC has been described as useful in acrylics, urethanes, epoxies and alkyd systems. DMC is miscible with almost all organic solvents DMC would easily replace oxygenated solvents like esters, ketones & glycol ethers DMC can replace alcohols, aromatics and aliphatics with appropriate co-solvents and/or reformulation work DMC in Waterborne Systems • DMC being an ester, can hydrolyze in acidic and basic conditions to methanol and carbon dioxide. • DMC may be stable in neutral conditions with suitable buffers, although formulators need proper care to prevent CO2 build up • DMC’s primary usage area should be in all solvent borne systems, where residual water does not normally cause hydrolysis issues DMC Expected Uses • DMC has shown promise in Auto refinish, with its favorable solubility, odor, evaporation rate and economic profiles • Industrial coatings for coating parts and architectural components at factories have shown similar appeal. • Also used in traffic paints, steel drum linings, floor coatings, concrete sealers • Can also be an effective paint thinner & multipurpose solvent, as is or as co-solvent DMC’s Odor Profile • One of DMC’s most favorable properties is a mild and non-offensive odor. • PCBTF and Tert-Butyl Acetate odors are much more pronounced and pungent • Noxious solvent odors are perhaps the most important concern of neighbors to body shops, factories, print shops and other industrial settings • Mild odor is well received by workers handling DMC or used in their work areas DMC Cost & Supply • DMC pricing is just below $ 1.00/lb, making it price competitive with most oxygenated solvents except possibly acetone. • Drums and bulk isotanks readily available from multiple factories in China. DMC is used in very large volumes in China for coatings primarily because of its low cost. • Totes can be filled from isotanks. • Long term a bulk tank in USA is possible DMC – Toxicity • DMC (like all methyl esters) rapidly deesterifies in the body to methanol & CO2 • DMC has low acute oral toxicity (LD50 rat 12,900 mg/Kg, LD50 mouse 6,000 mg/Kg) • DMC was found to be negative in mutagenic tests (in vitro Ames & comet assay) • Readily biodegradable and has low potential to bio-accumulate or be persistent in environment • Not expected to be toxic to fish or bacteria (possibly toxic to algae) DMC & Methanol toxicities • EPA feels teratogenicity is major endpoint health concern of environmental exposure for Methanol (and therefore DMC) • DMC is not mutagenic or genotoxic • Well run study by Exxon/Mobil on DMC’s teratogenic potential confirms it is virtually identical to Methanol’s (NOEL 1,000 ppm) • Kowa recommends an 8 hour industrial PEL of 100 ppm based on DMC’s toxicity profile California OEHHA Assessment • California's Office of Environmental Health Hazard Assessment issued a toxicity assessment of DMC in Dec.2009 that used the toxicity of its primary metabolite methanol and existing DMC studies to issue a toxicological assessment of DMC • Reported there were no concerns that DMC like methanol would be carcinogenic Calif. OEHHA Conclusion • OEHHA report concluded that doses levels of DMC likely to be achieved by environmental exposures to the general public by inhalation appears to have “relatively minor” environmental health concerns • Established interim acute and chronic REL, where the acute REL is identical to MEK’s and the chronic REL similar to Isopropanol’s DMC Azeotropes & Co-solvents • There have been a few cryptic references in literature to DMC forming azeotropes with numerous solvents without further data • Azeotropes using DMC could be the “wild card” in developing coating or cleaning formulations, substantially changing the evaporation rate, solubility and perhaps flammability profiles (to over 100 °F ?) • Using DMC & PC together might replace PCBTF, Xylene, butyl acetate, aromatic 100 Propylene Carbonate • Propylene Carbonate is a very slow evaporating solvent (evaporation rate <.005, BuAc =1). This will restrict its solvent use. • Low viscosity 2.4 cps, high flashpoint 253º F • Practically non-toxic by oral, dermal or Inhalation, slight skin irritant, eye irritant • Available from Kowa from same Chinese source as our Dimethyl Carbonate. Propylene Carbonate • Propylene Carbonate’s very low toxicity profile allows it’s use in cosmetic products, therefore PC safe for all consumer items • Readily biodegradable • Useful as a co solvent, wetting agent or tailing solvent (last solvent to evaporate). • Literature suggest can be used in binary & tertiary solvent systems to replace common solvents like trichlorethane and toluene BENZOTRIFLUORIDE - BTF • Proposed VOC exempt solvent, EPA recently tabled petition due to recently revised MIR values in 2009 • Low MIR of 0.28 (2009) should shortly be allowed for aerosol coatings on federal level, now allowed in Aerosol coatings in Calif. with a MIR value of .26 (2004 table) • Almost a direct replacement for toluene, similar solvency and evaporation rate (2.8)