Top Anchor Client Case Information

advertisement

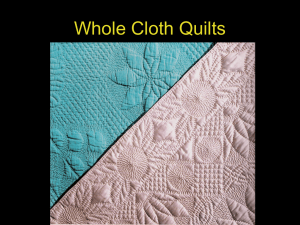

American Marketing Association Pittsburgh Collegiate Chapter 2016 Case Competition Introduction: Quilts A quilt is a cloth ‘sandwich’ with a top layer (quilt top), a filler (or batting) in the middle, and a ’backing’ on the bottom. The top layer is made with patches of fabric sewn together in blocks or other designs. The layers are combined or “quilted” involving stitching through all layers of the fabric. The history of quilts began long before European settlers arrived in the New World. People in nearly every part of the world had used padded fabrics for clothing, bedding, and even armor. With the arrival of the English and Dutch settlers in North America, quilting took on a new life and flourished. The quilt, as we know it in America, was originally a strictly utilitarian article, born of the necessity of providing warm covers for beds. Quilts were also used as hangings for doors and windows that were not sealed well enough to keep out the cold. Many Colonial women had to become creative in their use of materials on hand to keep their families warm during the cold seasons. Those early settlers could not afford to simply discard things when they wore out; necessity required they carefully use their resources. Therefore, when blankets became worn, they were patched, combined with other blankets, or used as filler between other blankets. These were not carefully constructed heirlooms, rather they were functional items for the sole purpose of keeping people warm. Only in later years, when fabrics were being manufactured in America and were more affordable, freeing women from the work of making their own yarns and fabrics, did the more artistic type of quilting become more widespread. In the mid 1800s the introduction of the sewing machine somewhat altered the dependence on hand-sewing. The invention of a separate quilting attachment for the sewing machine by Henry Davis of Chicago did not seem to be widely used; hand quilting remained the favored method for nearly a century. Through the 1950s and 1960s, there was less general interest in quilting than at any other time in American history. To many, the quilt was associated with lean times and “making do” – many viewed quiltmaking as dated and old-fashioned. It was primarily older quilters, those who had always quilted, who kept the art of quiltmaking alive during this time and passed the art down to their daughters and granddaughters. Then in the 1970s and 1980s a renewed interest in quiltmaking took hold. The backto-the-land movement, prompted by the anti-materialism of the late 1960s, generated a desire among many young people to learn hand skills that had been neglected in the postwar rush toward an automated society. Newly developed tools, new methods and new fabrics made the art new again. A milestone in American history, the Bicentennial celebration of 1976, was also a turning point in the history of quilts in America. The quilt became popular as a means of expressing national pride and achievement, and a powerful reminder of our past. Now, in yet another century, quiltmaking in the early 2000s is still practiced as it always was, though now more for relaxation than out of necessity. Some quilters follow the craft as a leisure-time activity or because it represents a tradition they find emotionally significant. Some have turned quilting into a successful business, while others have found in quiltmaking an artistic medium they can manipulate to their ends, and have ultimately created new styles and techniques. (Adapted from Quilting in America available at http://www.quilting-in-america.com/History-ofQuilts.html ) Quilters have several options for finishing quilts by machine. While some quilt on a standard domestic sewing machine using a variety of methods and tools, others invest in some type of dedicated quilting machine such as a ‘sit down’ machine or a much larger and more expensive longarm sewing machine. Others send their quilts to professional quilters to complete the quilting process. These individuals love the work of designing and piecing their quilt tops but don’t have the ability, time or talent to do the decorative quilting they want on their finished quilt. Gammill, Innova, APQS and HandiQuilter are among many companies that are the leading longarm quilting machine manufacturers with more companies entering the market all the time. Makers of some domestic machines are also starting to make their own sit down or longarm machines, such as Babylock, Bernina, Juki and Janome. Overview of TopAnchor Quilting Tools Ms. Bland has a BS in Graphics/Fine Arts from Fairmont State University. She was self-employed for many years producing trade shows primarily in the Seattle area but also in Phoenix, Albuquerque, Tucson and other southwest cities. She also worked mainly in construction management in the Pacific Northwest for many years. Upon retirement, she decided to set up a quilting business in her home and began checking out the various longarm quilting machines available. She had learned to quilt when quite young but back then, the quilt sandwich was mounted on a frame and hand quilted. One of the better known and easiest hand stitching patterns is the Baptist Fan, which naturally follows the sweep of the arm from right to left (or left to right for left-handers). After stitching from top to bottom in an arc, the thread is knotted and cut, then the stitching begins again at the far right and down again. See Figure 1 for an example of a Baptist Fan. Figure One: Baptist Fan Pattern Reasoning that there had to be a way to stitch the Baptist Fan pattern with a longarm machine, she began searching for a method to do just that. One big obstacle was that with a longarm, it’s desirable to stitch as far as possible without cutting the threads but the hand stitching method required cutting the thread after every sweep. This was overcome by stitching down in one arc, then stitching the next arc back up again from left to right, a movement that was possible with a longarm. With this movement in mind, the next thing was to design a device that would guide the machine in stitching concentric arcs. With some computer graphic design work and a rudimentary shape with notches on both sides took shape. Next came what turned out to be the hardest and most time consuming part of all – how to fasten the template to the quilt in a way that would allow it to rotate with the longarm. After more than a year and many trials and failures, she designed a very simple device with crossed pins that fastens to the top of the quilt and holds the template stable while allowing it to rotate. Upon advice from her new manufacturer, she applied for a patent and put the first template – the Baptist Fan template – on the market. Ms. Bland developed a “rotating template” system. A rotating template has a geometric shape that guides the ruler foot of a sewing or quilting machine. After one portion of the design is sewn, the tool is rotated around a stationary post and the stitching is continued along the guide path until the stitching returns to the starting point. Use of this rotating template system makes quilting various designs much easier without the need to premark the quilt top, walk behind the machine to make adjustments or operate the machine, and other activities that make it necessary for the quilter to move away from the stitching area during the quilting process. Since the introduction of that first template in December 2012, several more designs (Feather Wreath, Dahlia, Five-point Stars, Eight-point Stars, Infinite Star, HexStar templates) have been introduced. The Celtic Knot template is the newest and will go on sale in late September. (It is this template that should be the focus of the competition.) There are many ways for a quilter to manually transfer patterns onto a top for the quilter to follow. The options include stencil and chalk or marking pens, shaped rulers, pantographs (printed patterns following using a stylus fastened to the machine), rulers & templates, groovy boards, and large mechanical devices like the Circle Lord. Expensive computer robotic quilting systems are also available and are used by many professionals. The cost of rotating templates invented by Ms. Bland are necessarily more expensive than stencils and simple longarm rulers or templates, but cost much less than mechanical and computerized devices used to create quilting patterns. Rotating machine quilting templates by TopAnchor Quilting are made and assembled in USA with top quality materials and workmanship. They are precisely laser-cut from top grade acrylic and are screen printed with special permanent screened inks that will stay clear and bright without coming off. The “Baptist Fan” was the first template developed by Ms. Bland (the template featured in Figure 2 for a Baptist Fan). After nearly two years in research and development, a patent for rotating templates and the Baptist Fan template was finally introduced to the longarm quilting market in 2012. Figure Two: Baptist Fan Quilting Template in Use Since the initial introduction, TopAnchor has introduced six additional templates: Feather Wreath, Five and Eight Point Star (2013), Hex Star (2014), Infinite Star and Dahlia (2015) plus some additional accessories. TopAnchor Distribution and Promotion: At the start, the templates were sold via a store front in Amazon (http://www.amazon.com/TopAnchor/b/ref=bl_dp_s_web_10064669011?ie=UTF8&no de=10064669011&field-lbr_brands_browse-bin=TopAnchor ) In March, 2014 TopAnchor launched a website (www.topanchorquilting.com ) where customers can order products, view demonstration videos, access blogs, events and other services. Since its launch, the website has had 42,000 page views and 31,000 unique visitors. TopAnchor’s Facebook page has 6300 followers, and her youTube video channel has 400 subscribers and 46,000 views. TopAnchor has had some limited distribution with retailers however this has occurred opportunistically with few repeat orders. Ms. Bland speculates that the templates must “sell themselves” in a retail environment and this has been hard to achieve mainly because most stores don’t have personnel trained in the use of the tool and are therefore unable to present them to customers effectively. Ms. Bland has exhibited at Quilting Shows including the 2014 Machine Quilters Exposition in Manchester, NH , WV Quilters Festival in Bridgeport, and the AQS Quiltweek in Lancaster, PA. While there have been direct sales at shows, the monetary and energy cost of setting up and operating a booth for multiple days is burdensome. In addition, each show takes approximately a week’s absence from the business and someone must be hired to maintain the office, website and fill orders during her absence. In terms of advertising, TopAnchor has advertised on Amy Johnson’s blog (http://www.freemotionquiltingadventures.com/ ) that has generated modest levels of website traffic…upwards to 50 clicks per day.) This blog charges a very reasonable $75 per month to advertise. Johnson has been hired to make videos demonstrating quilting on a home sewing machine. The cost is $100 for each video using a specific template. The TopAnchor Facebook page (https://www.facebook.com/TopAnchorQuiltingTools?fref=ts has 6,300 likes. Currently, there is a growing number of firms who offer competition: Quilters Rule, The Gadget Girls, Quilters Apothecary, HandiQuilters and Westalee. Some other quilters design and produce their own rulers and templates. TopAnchor is on track to generate $60,000 in gross sales for 2015. Gross margins have been 10% (wholesale to shops) to 55% (direct retail sales). The sales history has been: 2012: $800 (was sold for only 2 weeks in Dec 2012) 2013: $25,000 2014: $48,000 Sales come from across the USA and Canada with about 3% of sales from overseas to approximately 20 other countries. Industry Overview 1 Quilting is a vibrant industry with sustained growth over multiple decades. This growth is driven by high value customers known as “dedicated quilters” who account for the majority of the industry’s revenue. Dedicated quilters do not view quilting as a hobby, but as an expression of themselves. This causes them to continue to look for new and innovative tools to improve the quality of their quilts. Quilting magazines and quilting websites are heavily relied upon when learning about new quilting tools, equipment, and supplies. In 2014, U.S. consumers spent $3.76 billion a year on quilting (e.g., sewing machines, sewing machine accessories, fabric, and thread). The industry has seen rapid growth 1 From the Quilting in America™ 2014 Survey presented by F+W, A Content + eCommerce Company over the last 15 years with total quilting revenue tripling from 1997 to 2014. This was growth was sustained by the 16.4 million individuals that actively quilt. Of those 16.4 million quilters, just over 2 million (12.2%) are what is termed dedicated quilters. Dedicated quilters spend at least $500 a year on quilting related purchases (compared to the average quilter whom spends $298 a year) and are responsible for generating over 60% of the quilting industry’s annual revenue. These dedicated quilters are typically women with an average age of 64 years old. They are well educated (79% attended college) and affluent (average household income $101,080). On average, the dedicated quilter spends $3,296 a year on quilting and possesses $12,861 worth of quilting tools and supplies. The dedicated quilter obtains quilting information through multiple sources. On average, they purchase 3.6 quilting books a year and subscribes to 3.7 quilting magazines. Quilting magazines are purchased not only to learn about new tips and techniques, but also as a way to learn about new products. In addition, quilting magazines have the added benefit of introducing quilters to web content with 53% of dedicated quilters learning about some of their favorite quilting websites through quilting magazines. The dedicated quilter possesses at least a basic competence with the internet. This is demonstrated by 87% owning a table or eBook reader and 86% accessing the Internet on a daily basis. This leads to dedicated quilters spending 3 hours a week visiting quilting related sites and 3.5 hours a week watching online broadcasting related to quilting. In addition, to finding inspiration for their projects and learning new techniques, this high level of web involvement leads to the purchase of new fabrics, quilting tools, equipment, and supplies online. The Challenge As TopAnchor begins its fifth year, much of the “preliminaries” have been achieved for this start up including manufacturing sourcing, product development, distribution and promotion. Ms. Bland would like to see sales double in 2016 and is interested in a marketing plan to achieve that goal. In addition, Ms. Bland questions a number of earlier decisions including: -What is the optimal distribution strategy? -Is the price competitive? Too high? Too low? -How can TopAnchor promote itself recognizing this firm is essentially a one person operation and has limited time to manage social media and other forms of advertising. Copyright @ 2016 by Michael F. Walsh. This case is prepared as the basis for a case competition rather than to illustrate either an effective or ineffective handling of an administrative situation.