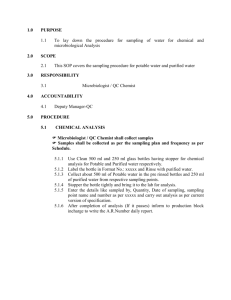

Physical Chemical Editted - EIN Uganda Clearinghouse

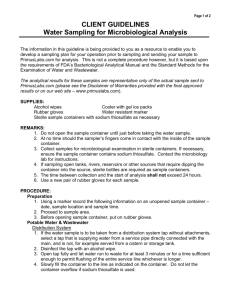

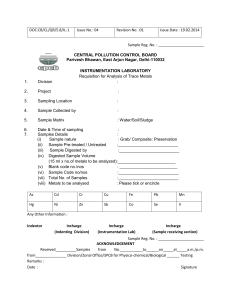

advertisement