Specific Heat Trials

Comparison of an Unknown Pure Metal Sample and Known Tungsten Sample

Keegan Laporte and Trevor P Balfour

Macomb Math Science Technology Center

Honors Chemistry – 10B

Mrs. Dewey, Mrs. Hilliard, Mr. Supal

May 20, 2013

Table of Contents

Introduction ........................................................................................................... 1

Background .......................................................................................................... 2

Review of Literature

Specific Heat .............................................................................................. 5

Thermal Expansion .................................................................................... 7

Problem Statement ............................................................................................... 9

Experimental Design

Specific Heat ............................................................................................ 10

Thermal Expansion .................................................................................. 13

Data and Observations ....................................................................................... 16

Data Analysis and Interpretation ......................................................................... 25

Specific Heat ............................................................................................ 27

Thermal Expansion .................................................................................. 32

Conclusion .......................................................................................................... 37

Acknowledgments .............................................................................................. 40

Appendix

Appendix A – ........................................................................................... 41

Appendix B – ........................................................................................... 42

Appendix C

– ........................................................................................... 43

Appendix D

– ........................................................................................... 44

Appendix E – ........................................................................................... 45

Appendix F – ........................................................................................... 47

Appendix G – ........................................................................................... 48

Work Cited .......................................................................................................... 49

Laporte-Balfour 1

Introduction

The research described in this paper was used to determine the identity of an unknown metal compared to the intensive properties of a known rod sample of tungsten. The properties that are used to determine the identity of the unknown metal sample are specific heat and the coefficient of linear thermal expansion. These properties are intensive, this means that they are dependent on the molecule and molecular structure of the material, and are not affected by the quantity and size of the sample.

The objectives of this research are to determine if the unknown metal sample is the same as the known tungsten sample by measuring both samples’ intensive properties and comparing them.

Using polyvinyl chloride or PVC piping homemade calorimeters made and used for measuring the specific heat of each metal and the percent error was compared to the known specific heat value of tungsten. This percent error was used to estimate the effectiveness of the experimental design. The coefficient of linear thermal expansion was found using a thermal expansion apparatus that measured the change in length. The percent error of the results was gathered to assess the errors in the experiment.

A two sample t test was performed on the data of both experiments to measure the difference in the means of their subsequent trials of tungsten and unknown samples. The t score value is a calculation in standard deviations away from the sample mean of the tungsten sample. The measurements determined

Laporte-Balfour 2 by this calculation showed that the two metals had different means at an alpha level of .10. This evidence led the researchers to believe that the metals were made up of different substances.

The final results of the researcher used the t test and percent error of the experiments to determine that the metals were actually made up of the same metal tungsten.

Background

Tungsten (Swedish for “Heavy Stone) was discovered in 1783 by Juan

José and Fausto D’Elhuyar. Its chemical symbol ‘W’ comes from its earlier

Germanic name, Wolfram, which was found in a metal ore called wolframite. The most common use of tungsten is for it to be alloyed with steel to form tough metals that are stable at high temperatures. Tungsten also has the highest melting point and the highest tensile strength of any other metal ("Chemistry

Explained").

To mine tungsten, ore is crushed and milled to break up the tungsten crystal from the scheelite, or wolframite ore and the rock is then sorted and separated from the gangue materials found in the ore using electromagnetic techniques. Purification of tungsten is done by cleaning and treating with different alkalis to form tungsten trioxide. This is then separated by heating the tungsten with hydrogen gas to create pure tungsten in a powdered form.

Laporte-Balfour 3

WO

3

+ 3H

2

W + 3H

2

O

The formula above shows the process of heating tungsten trioxide in the presence of hydrogen gas, H

2

. This releases pure tungsten as well as water vapor into the air.

The introduction of tungsten and its alloys into the design of incandescent light bulbs and the improvement of steel has made tungsten very valuable in metal work. Today tungsten carbide, WC, is one of the most durable materials made and is commonly used to strengthen cutting tools and is combined with steel to improve durability.

Tungsten has many unique properties that are used in metal works and manufacture. An example is tungsten’s high density of about 19.25 g/cm 3 ; this is almost 20 times the density of water. The most useful of these properties however are

Tungsten’s exceptionally high melting point and its conductivity which allows tungsten to be the main metal in “TIG”, or tungsten inert gas welding. A common technique used by metal workers that uses tungsten as an electrode. Tungsten also has an especially low thermal expansion coefficient, or alpha level of 4.3 °C -1 . This means that when heated at the same rate a tungsten rod will expand significantly less than a steel rod of the same size because it has an alpha level of 13.0 °C -1 , more than three times that of tungsten. The specific heat of tungsten is relatively high at about 24.27 J/g close to the same specific heat of other valuable metals such as titanium measured at 25.06 J/g.

Laporte-Balfour 4

The melting point of tungsten is 3410 degrees Celsius and has the highest melting point of any metal. Tungsten has five naturally occurring isotopes and 33 artificially synthesized isotopes virtually stable isotopes, making it an extremely stable element and with an atomic mass of 183 amu, it is also one of the densest elemental metals.

All of tungsten’s electron shells are filled, with the exception of the final subshell, which only contains four out of a possible ten electrons. Even though the “d” subshell only has four electrons, it is especially stable because according to Hunds Rule, for a given term, in an atom with outermost subshell half-filled or less, lies lowest in energy. It contains two valence electrons because of this.

Tungsten also has an atomic mass of 183.85 amu with an atomic number of 74; meaning that it contains 74 protons and 109 neutrons.

[Xe] 4f 14 5𝑑 4 6𝑠 2

The above condensed electron configuration displays arrangement of the subshells of tungsten’s electrons. As can be seen the “d” subshell has not been filled completely. Even though it is not filled Hund’s rule allows tungsten to be a relatively stable metal in its elemental form.

Laporte-Balfour 5

Review of Literature

Specific Heat:

In an experiment called “Experiment 2, the specific heat of Aluminum” the procedure for determining the specific heat of aluminum describes the use of a double Styrofoam cup as a calorimeter in measuring the temperature of water and the final temperature of the water and heated aluminum cube. Another experiment that determined specific heat of water was done by Brian and Daryl in their second experiment where they used a calorimeter and placed hot water into the calorimeter of cold water. They then measured the temperature of the mixed water after 30 seconds of stirring (“carsoncity.k12.mi.us”).

The formula below is used to calculate the temperature of the metal rod and the water individually while they are in the calorimeter.

Q =

SM∆T

This formula shows the heat at a constant pressure, ‘Q’ equals the specific heat ‘S’, times the mass of the rod or water ‘M’, times the change in temperature

(“Hilliard”).

SM∆T= SM∆T

The formula above is used to determine the specific heat rod when the reaction is at equilibrium and the temperature of the heated metal rod and its surrounding (water) reach the same temperature. The ‘M’ is the variable for the mass, the ‘S’ is for the specific heat, and the ‘∆T’ or delta T is for the change in

Laporte-Balfour 6 te mperature. The left part of the formula represents the rod and the water’s mass, specific heat and change in temperature is on the right. Since the heats of the two parts are equal to each other the specific heat can be properly measured in kJ/kg C (“Heat, Work and Energy”).

The experiments are good references of what our research will be investigating, and they mimic the techniques that will be used during our experiment. In ”Experiment 2 The Specific Heat of Aluminum." The experimenters used the procedure of combining the metal and water and measuring the combined temperatures. This will be used in this experiment to determine the specific heat of the tungsten rod and the unknown metal; also,

Brian and Daryl describe their using a calorimeter for their experimental design, a procedure that our researchers will be adopting to ensure minimal heat loss during the experiment.

Specific heat will be a key component in determining the identity of the unknown metal. The important aspect of specific heat is that it is a measurement of how much thermal energy a gram of a substance can absorb before it increases one degree Celsius. this ability for specific heat to be used as identification method is due to the fact that it is an intensive property, or a property that is constant not dependent on how much there is. More specifically, two quantities of a substance can be determined using an intensive property no matter how much of either substance there is because of the molecular structure of the material, this differs from extensive properties such as mass and volume which measure based the quantity of the material (

“hyperphysics.html”).

Laporte-Balfour 7

Linear Thermal Expansion:

The linear coefficient of thermal expansion is the measurement of change in a material’s length when it is heated. This expansion can be explained by the kinetic molecular theory which has to do with how the molecules move when thermal energy is added to the system. When a material is heated the molecules’ vibration increases in relation to the amount of thermal energy added to the system causing the material to expand proportionately to the coefficient of the material. This is because the coefficient is an intensive property, and is the same no matter the quantity of the substance only what it is made of. Measuring the coefficient of linear thermal expansion is a necessary and important factor in a large number of architectural and manufacturing backgrounds such as bridge building, metalworking and bone replacement (“Thermal Expansion of Solids and

Liquids”). Depending on the material being measured, different designs offer different options to determine the linear thermal expansion. The best methods for measuring pure metals are explained here.

In an experiment conducted to measure pure solid tungsten, the experimenters investigated the linear thermal expansion of the metal at a variety of temperatures from -

100°C to 500°C using a liquid bath chamber and a gas bath chamber ( “Thermal Expansion of Tungsten”; “Measurements on the

Thermal Expansion of Fused Silica”). The method of measurement with the liquid bath chamber had the metal being tested clamped into the center of the chamber and heated using electrodes at either end. The liquid bath chamber is filled with oil so to keep the air

’s oxygen from combining with the heated metal tungsten at

Laporte-Balfour 8 higher temperatures, and the gas bath chamber used for higher temperatures used an inert gas to keep the metal from oxidizing at extreme temperatures. A micrometer caliper was attached the metal to ensure precise measurement before and after heating.

Another design of measuring the linear coefficient was laid out in an experiment designed by Dublin City University for their college students. This experiment used a steam generator to heat up liquid water to constant temperature and be pour into a copper tube to be raised to a constant temperature. When the heat measured by a thermistor is equal throughout the copper tube, the length of the tube is measured and the linear coefficient of the metals thermal expansion is calculated.

The methods to calculate the linear coefficient of thermal expansion of a metal measures the metal’s change in length. 𝑎 =

(𝐿 𝑖

∆𝐿

∗ ∆𝑇)

The equation above can be used to determine the coefficient of linear thermal expansion of an object. ‘ ∆𝐿 ’ represents “delta length” or the change in length of the metal before and after it has been heated. ‘ 𝐿 𝑖

’ is the initial length of the metal rod measured at room temperature, and ‘ ∆𝑇 ‘is the change in the temperature of the rod from before to after the experiment. The coefficient, ‘a’ is measured in inverse degrees Celsius

(“Raymond, Jimmy”; “Thermal Expansion”).

Laporte-Balfour 9

Problem Statement

Problem:

To determine if an unknown metal is tungsten by determining its properties of specific heat and the linear thermal expansion.

Hypothesis:

When an unknown metal is tested based on its intensive properties of linear thermal expansion and specific heat, it is to be inferred that the unknown metal will be correctly identified as tungsten based on experimental data with a percent error of 15%.

Data:

The length of the rod will be measured in millimeters. The thermal expansion coefficient of the rod will be measured in °𝐶 −1

, or inverse degrees

Celsius. The temperature of the rod and the water in the calorimeter will be measured in °C. The specific heat of the rods will be calculated by using the formula below. See appendix A for specific heat sample calculation.

SM ∆ T= SM ∆ T

Shown in the formula above the “s” is for the specific heat capacity, “m” is for the mass in grams, and “ ∆ t” is for the change in temperature as the metal cools.

Laporte-Balfour 10 𝑎 =

(𝐿 𝑖

∆𝐿

∗ ∆𝑇)

Shown above is the formula going to be used to calculate the coefficient of thermal expansion. The coefficient “a” equals the change in length divided by the product of the initial length times the change in temperature. See appendix B for sample calculation.

Specific Heat:

Materials:

Ti-Nspire CX Graphing Calculator

Wool Glove

(2) Unknown Metal Rod

(2) Tungsten Rod

Logger Pro Thermometer Probe .1°C

50 mL Beaker

Excel Spreadsheet

Temperature probe

100mL Graduated Cylinder

Experimental Design

Calorimeter (4)

Logger Pro

50 mL of Water

Hotplate

Digital Thermometer .1°C

Scout Pro Electronic Scale .1g

Loaf Pan

Tongs

Laporte-Balfour 11

Wool Glove

Loaf Pan

Digital

Thermometer

Tongs

Unknown

Rods A and B

Graduated

Cylinder

Figure 1. Materials Used for Specific Heat Trials.

Calorimeters

Logger Pro

Thermometer

Probe

Ti-Nspire

Hot Plate

Figure 1 shows all materials used in the specific heat trials.

Procedure:

Specific Heat Trials:

1. Randomize 15 trials for the known and unknown metal using the Ti-Nspire calculator, see appendix C for detailed instructions on how to randomize.

2. Preheat water to 100 °C by setting a beaker filled with 50 mL of water onto a hot plate.

3. Plug in thermometer probe to the logger pro and calibrate gathering info

(see appendix D for how to calibrate the logger pro)

4. Add 100°C water into the calorimeter (see appendix E for calorimeter construction).

5. Insert temperature probe (attached to logger pro) down the hole on the top of the calorimeter before inserting the metal.

Laporte-Balfour 12

6. Submerge the metal rod A/B into the calorimeter after the temperature probe has collected data for two minutes. DO NOT remove the temperature probe before inserting metal.

7. Allow the heated metal rod to remain submerged for five minutes or until it has reached equilibrium with the water.

8. Unscrew the cap of the calorimeter and remove rod A or B from the calorimeter.

9. Repeat steps 4-8 for 14 more trials for known rods A and B and 15 more for unknown metal rods A and B.

Figure 2. Specific Heat PVC Calorimeter

Shown in figure 2 the calorimeters were used to act as an isolated system for the heated rod to reach equilibrium with the heated metal rod. The pipe insulator as well as the PVC itself was designed to keep the heat of the metal rod from escaping to properly measure the specific heat of the metal.

Digital

Thermometer

Loaf Pan

Metal Tongs

Hotplate

Unknown

Metal Rods

Laporte-Balfour 13

Linear Thermal Expansion:

Materials:

Ti-Nspire CX Graphing Calculator

Caliper (Proper Name Needed)

(2) Unknown Metal Rod

(2) Thermal Expansion Jig Apparatus

Logger Pro Thermometer Probe .1°C

Spray Bottle (100 ml)

Excel Spreadsheet

100 mL Graduated Cylinder

Jig

Caliper

100 mL

Graduated

Cylinder

Ti-Nspire

Wool Glove

Figure 3. Materials for Linear Thermal Expansion Trials

Stainless Steel Tongs

Logger Pro

Temperature Probe

(2) Tungsten Rod

Digital Thermometer .1°C

Hotplate

(2) Loaf Pan (19 X 8.5 X 6)

Figure 3 shows all of the materials used for the linear thermal expansion trials. Not shown is a spray bottle that was filled with water to cool down the metal rod more quickly while being measured.

Laporte-Balfour 14

Procedure:

Thermal Expansion Trials:

Safety: Observe all lab safety procedures, use tongs when removing heated metal rods from water.

1. Randomize rods A and B for the known and unknown metals. See appendix C for instructions randomizing using the Ti-Nspire CX Graphing

Calculator. Make sure the rods each have an either 7 or 8 trials

2. Measure the length of rod A and B. Record length in an Excel spreadsheet.

3. Pour 400 mL of water into a loaf pan and heat to 100°C using the hotplate.

Cover up the loaf pan containing water with another loaf pan so the water will come to a boil faster. Water will have to constantly be added at 20 mL increments throughout the trials.

4. Periodically check the temperature using the digital thermometer.

5. Once the temperature stabilizes at 100°C, heat the metal rod by laying it in the loaf pan of boiling water and allow it to heat up for three minutes.

6. Remove the metal rod from the boiling water by using the tongs and quickly place into the jig.

7. Mark the initial tick mark on the dial with a washable marker as fast as possible.

8. Spray the metal rod with the spray bottle in order to hasten the cooling process.

Laporte-Balfour 15

9. After three minutes, log the final tick mark and calculate the change in length.

10. Remove the metal rod from the jig and lightly touch it with the digital thermometer to measure the final temperature.

11. Record the change in length and the final temperature in an Excel spreadsheet.

12. Repeat steps 2-10 for 14 more trials for known rod A and B and 15 for unknown metal rods A and B.

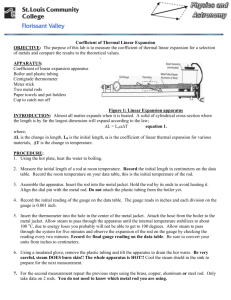

Figure 4. Tungsten Rod A in Thermal Expansion Jig Apparatus

Figure 4 shows tungsten A rod inside of the jig Apparatus. The researchers measured each rod sample for its change in length when it was removed from the loaf pan of boiling water.

Laporte-Balfour 16

Data and Observations

Data:

Table 1

Specific Heat Data Table of Tungsten Rod Samples

Trial

9

10

11

12

13

14

15

Average

4

5

6

7

8

1

2

3

B

A

B

A

B

A

B

A

B

A

B

A

B

A

A

Rod

Initial Temp.

(°C)

Water Metal

23.1 100.0

22.6 100.0

23.0 100.0

18.5 100.0

21.8 100.0

23.2 100.0

21.2 100.0

21.5 100.0

21.3 100.0

20.8 100.0

19.4 100.0

19.4 100.0

20.8 100.0

21.4 100.0

21.5 100.0

21.3 100.0

Equilibrium temp. (°C)

26.4

Change in

Temp. (°C)

Mass

(g)

Water Metal Metal Water

3.3 73.6 75.99 30

26.6

26.0

4.0

3.0

73.4 76.00

74.0 75.99

30

30

23.1

26.0

27.0

25.0

25.1

4.6

4.2

3.8

3.8

3.6

76.9

74.0

73.0

75.0

74.9

76.00

75.99

76.00

76.02

76.02

30

30

30

30

30

25.3

24.4

23.4

23.4

24.4

24.7

25.3

25.1

4.0

3.6

4.0

4.0

3.6

3.3

74.7

75.6

76.6

76.6

75.6

75.3

76.01

76.00

76.01

76.01

76.03

76.01

3.8 74.7 76.01

3.8 74.93 76.01

30

30

30

30

30

30

30

30

Specific

Heat

(J/g°C)

0.074

0.090

0.067

0.099

0.094

0.086

0.084

0.079

0.088

0.079

0.086

0.086

0.079

0.072

0.084

0.083

Shown in Table 1, the data collected from the specific heat trials recorded into the spreadsheet show the measurements taken from the two known rods of tungsten. These values were used to calculate to specific heat of each trial.

Laporte-Balfour 17

Table 2

Specific Heat of Unknown Rod Samples

Trial Rod

Initial Temp.

(°C)

Water Metal

9

10

11

6

7

8

12

13

1

2

3

4

5

14

15

Average

B

A

A

B

A

B

A

B

B

A

A

B

A

B

A

20.0

24.1

20.6

23.0

22.7

23.9

23.6

23.1

25.0

23.2

23.2

23.9

21.4

25.4

25.0

23.2

99.2

99.9

99.9

99.5

99.5

99.3

99.3

99.0

98.0

98.0

99.3

99.3

99.2

99.0

99.5

99.2

Equilibrium temp. (°C)

Change in

Temp. (°C)

Mass

(g)

Water Metal Metal Water

Specific heat

(J/g°C)

4.5

4.5

4.6

4.7

4.3

4.2

4.5

4.6

2.1

5.9

4.4

3.7

4.8

3.9

4.2

4.3

24.5

28.6

25.2

27.7

27.0

28.1

28.1

27.7

27.1

29.1

27.6

27.6

26.2

29.3

29.2

27.5

70.9 79.12

68.9 78.06

71.7 79.14

71.7 78.09

73.0 79.17

74.7 78.08

71.3 79.18

74.7 78.08

71.8 79.14

72.5 78.11

71.2 79.15

71.2 78.08

71.3 79.28

69.7 78.08

70.3 79.13

71.7 78.66

30

30

30

30

30

30

30

30

30

30

30

30

30

30

30

30

0.047

0.138

0.097

0.083

0.104

0.097

0.100

0.099

0.104

0.095

0.094

0.102

0.102

0.090

0.095

0.096

Table 2 shows the data of the measurements of the two unknown rods taken during the experiment. This data was used to calculate the specific heat of the each rod.

Table 3

Linear Thermal Expansion of Tungsten Rod Samples

Trials Rod

1

2

3

4

5

A

B

A

B

A

Length

(mm)

0.040

0.025

0.040

0.020

0.040

Length

(mm)

124.25

124.24

124.24

124.22

124.30

Initial

Temp.

(°C)

Final Temp.

(°C)

Alpha

Coefficient

(mm* 𝟏𝟎 −𝟔 )

98.2

99.8

99.0

100

99.1

23.9

23.6

26.6

26.4

24.6

4.333

2.641

4.457

2.198

4.329

Laporte-Balfour 18

Trials Rod Length

(mm)

Length

(mm)

Initial

Temp.

(°C)

Final Temp.

(°C)

Alpha

Coefficient

(mm* 𝟏𝟎 −𝟔

)

9

10

11

6

7

8

12

13

14

15

Average

B

A

A

B

A

B

A

B

B

A

0.030

0.030

0.025

0.035

0.035

0.040

0.030

0.025

0.020

0.040

0.032

124.24

124.31

124.27

124.23

124.25

124.28

124.31

124.30

124.25

124.23

124.26

100.1

100.2

99.0

99.1

100.0

99.9

100.0

99.8

98.2

98.2

99.37

23.9

25.3

26.0

24.1

25.6

27.2

29.0

23.4

24.3

25.4

25.3

3.169

3.222

2.756

3.756

3.786

4.427

3.399

2.633

2.178

4.423

3.445

Table 3 shows the recorded data from the thermal expansion experiment done on the two tungsten rod samples. This data was used to calculate the alpha coefficient of the linear expansion of the metal rods.

Table 4

Linear Thermal Expansion of Unknown Rod Samples

Trials Rod

Initial

Change in

Length

Length (mm)

(mm)

Initial

Temp.

(°C)

Final Temp.

(°C)

Alpha Coefficient

(mm* 𝟏𝟎 −𝟔

)

5

6

7

8

9

1

2

3

4

A

B

A

B

A

A

B

A

B

0.010

0.010 127.67

0.010 129.20

0.010 127.60

0.015 129.28

0.020 127.62

0.040 129.23

0.010 127.62

0.020

129.32

129.36

98.1

97.6

98.7

99.0

99.7

99.1

97.8

100

98.8

22.4

25.8

22.2

24.3

27.0

25.2

26.7

26.8

24.9

1.021

1.091

1.011

1.049

1.60

2.121

4.353

1.070

2.092

Laporte-Balfour 19

Trials Rod

Initial

Change in

Length (mm)

Length

(mm)

Initial

Temp.

(°C)

Final Temp.

(°C)

Alpha Coefficient

(mm* 𝟏𝟎 −𝟔

)

10

11

12

13

14

15 A

Average

B

A

B

A

B

0.020 127.70

0.020 129.29

0.020 127.69

0.020 129.26

0.010 127.73

0.030 129.27

0.020 128.52

99.0

99.9

100.0

100.0

98.5

100.0

99.1

27.1

27.2

26.0

26.6

26.6

25.6

25.6

2.188

2.138

2.127

2.118

1.089

3.119

1.876

Table 4 shows the data recorded from the thermal expansion experiment used to calculate the alpha coefficient of linear thermal expansion of the two unknown metal rods.

Table 6

Observations of Linear Thermal Expansion of Unknown Rod Samples

Trial

Linear Thermal Expansion of the Unknown Metal

Date Rod Jig Observations

1 4/17/2013 A 5

Two trials were conducted at once for all of the trials. The dial was not marked fast enough so the exact point that the metal rod began on is not known for sure.

2 4/17/2013 B 10

The researchers mistakenly forgot to record the initial temperature of the water. So it was not known if the metal rod was heated to the proper temperature

3 4/17/2013 A 5 no errors

4 4/17/2013 B 10

The rod on the jig was not sprayed. Trial took much longer than expected

Laporte-Balfour 20

Trial

Linear Thermal Expansion of the Unknown Metal

Date Rod Jig Observations

5 4/17/2013 A 5 no errors

6 4/17/2013 B 10 no errors

7 4/17/2013 A 5

Lid was not on top of the pan.

Metal most likely didn't reach optimal temperature because the water was giving off a lot of heat.

8 4/17/2013 A 10

Researchers had problems gripping the metal with the tongs so the metal was exposed to air a bit longer than desirable

9 4/17/2013 B 5 no errors

10 4/17/2013 A 10 no errors

11 4/17/2013 B 5

Boiling water was spilled from the pan while researchers were moving the metal around in it

12 4/17/2013 B 10

Jig was extremely moist before the rod was placed on it.

Because of this, the rod cooled and contracted faster than anticipated

13 4/17/2013 A 5 no errors

14 4/22/2013 B 10

The gloves were quite wet.

Metal rod cooled much faster upon removal

15 4/22/2013 A 5

The gloves were quite wet.

Metal rod cooled much faster upon removal

Table 6 shows the observation taken during the thermal expansion experiment for the unknown metal. The amount of time that it took to move the

Laporte-Balfour 21 metal rod from the boiling water to the jig was a critical moment. All of the linear thermal expansion trials are not exact because the rod began to contract as soon as it was removed from the water and it was difficult to place the metal correctly on the first try. Roles were the same though out. Researcher 1 collected data while Researcher 2 kept track of the time and transported the metal.

Table 7

Observations of Linear Thermal Expansion of Tungsten Rod Samples

Linear Thermal Expansion of the Known Metal

Trial Date Rod Jig Observations

1 4/22/2013 A 5

The dial that the researchers chose was in inches and they decided to discard this trial for convenience

2 4/22/2013 B 10 No Errors

3 4/22/2013 A 5

Boiling time was inaccurate. The rod was under boiled

4

5

4/22/2013

4/22/2013

B

A

10

5

Boiling time was inaccurate. The rod was under boiled

Rod slipped upon removal and fell back into the pan. May have begun to contract prematurely

6 4/22/2013 B 10 No Errors

7 4/22/2013 A 5 No Errors

8 4/22/2013 B 10

Researchers forget to take the Initial length measurement. They had to remove rods to measure them.

Laporte-Balfour 22

Linear Thermal Expansion of the Known Metal

Trial Date Rod Jig Observations

9 4/22/2013 A 5

Researchers forget to take the Initial length measurement. They had to remove rods to measure them.

10 4/22/2013 B 10 No Errors

11 4/22/2013 A 5 No Errors

12 4/22/2013 B 10

Researcher did not have the spray bottle at their disposal

13 4/22/2013 A 5

Researcher did not have the spray bottle at their disposal

14 4/22/2013 B 10 No Errors

15 4/22/2013 A 5 No Errors

Table 7 shows the observations from the linear thermal expansion experiment of the two Tungsten rods. Similar flaws occurred in the known trials as they did in the unknown trials.

Table 8

Observations of Specific Heat Trials of Unknown Rod Samples

Trial Date

1 4/19/2013

2 4/19/2013

Specific Heat of the Unknown Metal

Rod

Calorimeter

Number

Observations

B

B

2

4

Water measurement inside of the calorimeter was made as precise as possible with the resources that we had on hand.

A slight amount of water spilled out of the graduated cylinder during its transfer into the calorimeter. The trial was executed anyways because time was vital.

Laporte-Balfour 23

Trial Date

3 4/19/2013

4 4/19/2013

5 4/19/2013

6 4/19/2013

7 4/19/2013

8 4/19/2013

9 4/19/2013

10 4/19/2013

11 4/19/2013

Specific Heat of the Unknown Metal

Rod

Calorimeter

Number

Observations

A

B

A

B

A

1

2

3

4

1

Water measurement inside of the calorimeter was made as precise as possible with the resources that we had on hand.

No errors to report except for the time it took for the rod to be transferred from the boiling water into the calorimeter

Trial ran smoothly. Time to put the metal rod into the calorimeter was at an absolute minimum

Trial ran smoothly. Time to put the metal rod into the calorimeter was at an absolute minimum

Rod A was dropped while removing it from the boiling water. For the sake of time, the trial had to be conducted regardless.

A

B

A

3

2

1

Two trials are conducted simultaneously and the researchers adopt this for the rest of the trials.

Water was not at the ideal temperature. It was about 96 but the temperature did not appear to be rising any further so the trial was executed.

Tests were virtually unflawed. Error may have occurred when the rod was not transferred into the calorimeter fast enough.

B 4

Tests were virtually unflawed. Error may have occurred when the rod was not transferred into the calorimeter fast enough.

12 4/19/2013

13 4/19/2013

14 4/19/2013

15 4/19/2013

B

A

A

B

2

3

1

3

No Errors

No Errors

Tests were virtually unflawed.

Tests were virtually unflawed.

Possible saving error on the Logger

Pro.

Laporte-Balfour 24

Table 8 shows the observations of the specific heat trials of the unknown rod samples. All of these trials were run by Researcher 2 and recorded by

Researcher 1. For all of the trials, the main concern was the amount of time that it took to transfer the metal rod into the calorimeters. Errors were frequent because the researchers were overwhelmed. The roles were constant throughout. Researcher 1 gathered and analyzed data while researcher 2 transported the metals, measured the temperature of the water, and operated the logger pro.

Table 8

Observations of Specific Heat Trials of Tungsten Rod Samples

Trial

1

2

3

4

5

6

7

8

9

Date

Specific Heat of the Known Metal (Tungsten)

Rod

Calorimeter

Number

Observations

4/18/2013

4/18/2013

4/18/2013

4/18/2013

4/18/2013

A

B

A

B

A

1

2

3

1

3

No errors to report

No errors to report

No errors to report

No errors to report

Researcher 1 dropped this metal back into the pan on accident

4/18/2013

4/22/2013

4/22/2013

4/22/2013

10 4/18/2013

11 4/18/2013

B

A

A

B

A

B

4

1

2

4

3

1

Data collection was inconsistent because when Researcher 2 attempted to screw the cap back onto the calorimeter, the temperature probe fell out.

No errors to report

No errors to report

The rest of the known metal specific heat trials were completed.

Rods were severely over boiled by over a minute due to poor timing

It was discovered that the insulation on Calorimeter 1 was possibly flawed because it did not hug the perimeter of the PVC pipe.

Laporte-Balfour 25

Trial Date

Specific Heat of the Known Metal (Tungsten)

Rod

Calorimeter

Number

Observations

12 4/18/2013 B 3 No errors to report

13 4/18/2013

14 4/18/2013

15 4/18/2013

A

B

A

2

4

2

Rods were severely over boiled by over a minute due to poor timing

No errors to report

No errors to report

Table 8 shows the observations for the specific heat trials of the Tungsten rod samples. For all of the trials, the main concern was the amount of time that it took to transfer the metal rod into the calorimeter. The time of the rods in the boiling water was inconsistent.

Data Analysis and Interpretation

To determine the accuracy of the results of the specific heat and thermal expansion trials, the percent error of each trial was found. This is used to determine the validity of the experiment itself before the data can be tested.

Table 9

Percent Error of Specific Heat Trials

Trial

3

4

5

1

2

Known

Specific heat

(J/g* °C)

0.074

0.090

0.067

0.099

0.094

Known

Value of

Tungsten

0.134

0.134

0.134

0.134

0.134

Percent

Error

45%

33%

50%

26%

30%

Trial

3

4

5

1

2

Unknown

Specific heat

(J/g* °C)

Known

Value of

Tungsten

Percent

Error

0.047

0.138

0.097

0.083

0.104

0.134

0.134

0.134

0.134

0.134

65%

3%

27%

38%

22%

Laporte-Balfour 26

Known Unknown

Trial

Specific heat

(J/g* °C)

Known

Value of

Tungsten

Percent

Error

Trial

Specific heat

(J/g* °C)

Known

Value of

Tungsten

Percent

Error

6

7

8

9

10

11

12

13

14

15

Average:

0.086

0.084

0.079

0.088

0.079

0.086

0.086

0.079

0.072

0.084

0.083

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

36%

38%

41%

34%

41%

6

7

8

9

10

36%

36%

41%

11

12

13

46%

37%

14

15

38% Average:

0.097

0.100

0.099

0.104

0.095

0.094

0.102

0.102

0.090

0.095

0.096

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

0.134

Table 9 shows the percent error of the specific heat trials. The percent

30%

24%

24%

33%

29%

28%

28%

25%

26%

23%

29% errors of these trials are especially high from the known value of tungsten, and the ranges of these percent values, 26% to 50% for known and 3% to 65% unknown metal are very widespread. This is predicted to be caused by a large amount of errors during the experiment. See appendix F for sample calculation of percent error.

Table 10

Percent Error of Thermal Expansion Trials

Known

3

4

1

2

Trials

Alpha

Coefficient

(°C-1)

4.33

2.641

4.447

2.188

Known value of tungsten

(°C -1 )

Percent

Error

4.3

4.3

4.3

4.3

1%

39%

3%

49%

Trials

3

4

1

2

Unknown

Alpha

Coefficient

(°C -1

)

Known

Value of

Tungsten

(°C -1

)

Percent

Error

1.022

1.091

1.012

1.049

4.3

4.3

4.3

4.3

76%

75%

76%

76%

Laporte-Balfour 27

Trials

Known

Alpha

Coefficient

(°C-1)

Known value of tungsten

(°C -1 )

Percent

Error

Trials

Unknown

Alpha

Coefficient

(°C -1 )

Known

Value of

Tungsten

(°C -1 )

Percent

Error

8

9

10

5

6

7

11

12

13

14

15

Averages:

4.320

3.169

3.222

2.756

3.756

3.786

4.427

3.399

2.633

2.178

4.423

3.445

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

0%

26%

25%

36%

13%

12%

3%

21%

8

9

10

5

6

7

11

12

39%

49%

3%

13

14

15

21% Averages:

1.596

2.121

4.353

1.070

2.092

2.178

2.128

2.117

2.108

1.089

3.119

1.876

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

4.3

Table 10 shows the percent error of the thermal expansion trials. The

63%

51%

1%

75%

51%

49%

51%

51%

51%

75%

27%

57% percent errors of these trials were especially high due to a high number of errors in the experiment. See appendix F for sample calculation.

Specific Heat:

The data collected in two independent random samples by the specific heat experiments to determine if the two rods samples are made of the same metal will be analyzed using a two sample t test. This test is best used for the data of the two samples because the test compares two sample means without knowing the population mean or standard deviation.

Laporte-Balfour 28

The assumptions to perform this test must be met for the results to be considered valid. The first assumption of the t test is that the samples must be two independent simple random samples, or a SRS. This means that the trials were randomized before the experiment began and the data could not have been affected by a pattern. The data for the two specific heat experiments were randomized before each trial using the randomization function of the TI-Nspire calculator used in the experiment.

Figure 5. Probability Plot of Tungsten Sample Specific Heat Data

Figure 5 shows the probability plot for the tungsten specific heat trials.

This plot shows the normality of the trials compared to the line. This plot shows that the data is close to normal for the t test to be considered reliable.

Figure 6. Probability Plot of Unknown Sample Specific Heat Data

Laporte-Balfour 29

Figure 6 shows the probability plot of the specific heat trials of the unknown rod sample. The graph shows a non-normal behavior in the data of the unknown trials. A box plot of the data showing the two outer data points showed them as outliers. These data points were removed from the test to improve the accuracy of the t test.

Figure 7. Box Plot of Rod Samples

Figure 7 shows a box plot of both rod samples, two outliers are found in the unknown rod’s data. These outliers were caused by errors made in the lab in those trials.

Figure 8. Probability Plot of Unknown Specific Heat Data Without Outliers

Laporte-Balfour 30

Figure 8 shows an improved probability plot of the specific heat data. This data appears to have a normal distribution. This altered data set will be used in the t test to conclude the comparison of means.

Two Sample t Test:

The null hypothesis of the t test is that the sample means are the same, and the alternate hypothesis is that the mean of tungsten rod trials, 𝑥̅

1

, are different than the unknown rod trials, 𝑥̅

2

.

H

0

: 𝑥̅

1

= 𝑥̅

2

H a

: 𝑥̅

1

≠ 𝑥̅

2 𝛼 = .10

The two sample t test used the following formula to estimate the difference between the two sample means. 𝑡 =

(𝑥̅

1

√

(𝑠 𝑛

1

1

) 2

− 𝑥̅

2

)

+

(𝑠

2 𝑛

2

) 2

In this formula, the t score is the tungsten sample mean, 𝑥̅

1

, minus the mean of the unknown metal’s data, 𝑥̅

2

, divided by the square root of the tungsten rod data standard deviation, 𝑠

1

, squared over the number of trials for the tungsten rod sample, plus the unknown rod data standard deviation, 𝑠

2

, squared divided by the number of trials for the unknown sample. See appendix G for sample calculation.

Laporte-Balfour 31

Figure 9. Specific Heat Two Sample t Test

Using the Ti-Nspire calculator software, Figure 9 shows the results of the two sample t Test of the two specific heat samples. The results show all the variables needed for the calculation of the t score, -5.124, as well as the P value

0.000027 of the test.

Figure 10. Density Plot of Two Sample t Test of Specific Heat

Figure 10 shows the density plot of the t test of the specific heat trials. The non-shaded area of the plot shows the probability of the means to be the same.

The shaded area represents the difference in the means of the known and unknown rod samples. Both sides of the bell curve are shaded because it is not known which of the means is greater than the other, only the measured difference.

Laporte-Balfour 32

Conclusion:

The researchers reject the null hypothesis because the p value of .000027 is below the alpha level .10. This is valid evidence that the unknown rod sample is not the same metal as the sample Tungsten rod. If the 𝐻 𝑜

is true, there is only a .0027% chance of these results this extreme would be replicated by chance alone.

Thermal Expansion:

The data collected by the linear thermal expansion experiments will be analyzed using a two sample t-test. A two sample t-test was required because the population standard deviation and the population means are not known.

There are a few assumptions that must be met first. The first assumption is that the sample population of the trials was a simple random sample. The samples were randomized by using the Ti-Nspire graphing calculator. The second assumption is that the two populations are independent. The two populations must be independent because two different metals were being tested at two different times. The third assumption is that the populations are normally distributed. For both the known and the unknown metals, the populations may possibly be normally distributed but there are not enough trials to be conclusive without running a test or normality. The fourth and final assumption is that the standard deviation and the mean of the sample population are not known. The

Laporte-Balfour 33 test may still be run if all the assumptions are not met but the accuracy of the outcomes may be inconclusive.

Figure 11. Probability Plot for Alpha Coefficient of the Known Metal

Figure 11 shows that the data for the alpha coefficient of the known metal is close to normal. The small deviations in the plot could have been caused by different technical errors during the experiment which resulted in the data being more varied.

Figure 12. Normal probability plot for the alpha coefficient of the unknown metal

Figure 12 shows the probability plot for the unknown rod trials. The data is less normal than it is for the known metal. This as well is expected to be the result of experimental design flaws throughout the trials.

Laporte-Balfour 34

Two Sample t Test:

The null hypothesis says that the means of the two samples are equal, and the alternative hypothesis says that they do not equal:

𝐻 𝑜

: μ1 = μ2

𝐻 𝑎

: μ1 ≠ μ2

A two sample t test is used to compare the means of two different populations. The equation below is required in order to determine the t value. 𝑡 = 𝑥̅

1

− 𝑥̅

2

√ 𝑠 𝑛

2

1

1

+ 𝑠 2

2 𝑛

2 𝑥̅

1

Represents the sampling mean for the known metal while 𝑥̅

2

represents the sampling mean for the unknown metal. 𝑠

1

Represents the standard deviation for the known metal, and 𝑠

2

represents the standard deviation for the unknown population. 𝑛

1

represents the number of trials of the known metal and 𝑛

2 represents the number of trials of the unknown metal. See appendix G for a sample calculation.

Laporte-Balfour 35

Figure 13. Two Sample t Test of Thermal Expansion data

Figure 13 shows the t value as being 4.85058 and the p value as being

.000043. This means that these results are extremely unlikely of being duplicated by chance alone.

Figure 14. Graphed P Value of Two Sample t Test of Thermal Expansion

Experiment

Figure 14 visually displays the t value and P value for the two sample t test. The shaded area cannot be seen due to the high t value.

Laporte-Balfour 36

Figure 15. Box plot of Thermal Expansion Trials

Figure 15 displays the means of both the known and the unknown metals.

It is obvious that the mean of the known metal is much higher than the mean of the unknown metal and that the unknown metal contains an outlier. The box plot for the known metal is so big because the points are spread out enough to drastically affect the mean.

Conclusion:

The researchers reject the null hypothesis because the p value of .000031 is below .10. There is convincing evidence that the known metal is not the same as the unknown metal, but further tests may be run to validate these results.

There is a .003% chance of replicating these results this extreme by chance alone given that 𝐻 𝑜

is true. Due to the varied normal distribution of the data and the errors throughout the experiment, the results of the t test will be considered less valid than expected. These results and their validity will be determined more in the identification of the material.

Laporte-Balfour 37

Conclusion

The initial problem statement that was drafted at the inception of the experiment was to identify an unknown metal sample based on its intensive properties of linear thermal expansion and specific heat. From this, it was hypothesized that based on these properties, the hypothesis to determine the identity of the unknown metal within a 15% error would be correct. After much experimentation, the researchers concluded that the hypothesis was incorrect.

The original hypothesis was rejected because the percent errors for both specific heat and linear thermal expansion were too distant from the predicted/acceptable percent error of 15%. The percent error of the specific heat trials was 38%, this and the thermal expansion trials that had a 56% error showed that the data did not support the original hypothesis because of multiple inconsistencies in the experiment, these errors caused by variations such as transfer time and boiling time could have adversely affected the data.

The transfer time as the rod was being moved to either the calorimeters or thermal expansion apparatus allowed the metal time to cool unmeasured, this unknown temperature change could have caused the specific heat measurements to be inaccurate and the extra time would have allowed a varied amount of time for the rod samples to cool and contract before the change in length could be measured for thermal expansion. The time that it took to transfer the metal rod from the boiling water to the jig was crucial and was not consistent for all of the trials. The longer the metal was not inside of the jig, the more time

Laporte-Balfour 38 that it had to cool unmeasured. This error could have led to imprecise and inaccurate data that could have led the data to show a false result.

Another inconsistency was that the boiling time for each trial was not exactly the same as the previous trial. The variations in boiling time could have led to inconsistencies in linear thermal expansion measurements by altering the temperature of the rod when it was removed from the water. A very important assumption that was taken regarding the heating of the metal rod samples was to assume that when the rods were remove they were the same temperature of the water, if in any trial this assumption was not true the data would be less reliable.

Other than the problems previously stated above, experimental design was the primary blame for the inaccurate data measurements. The calorimeters not being perfectly insulated altered the specific heat results while the transfer and boiling time proved to be the major flaw in the linear thermal expansion trials.

If there was anything that the researchers would change about this experiment it would be to be granted more time, and proper measurement systems. If more timed was allocated to the experiment, the proper temperature of the rod could have been reached and maintained through a longer exposure to heat. This would have helped eliminate the error of boiling time and the linear thermal expansion trials would have yielded an alpha coefficient that was closer to support of the original hypothesis. Proper equipment would have allowed for the construction of better calorimeters and more accurate thermal expansion jigs that could have improved the results of the experiment through allowing less heat loss during transfer times. If the calorimeters were better insulated, the results for

Laporte-Balfour 39 the specific heat trials could have been more accurate than the current results. A more detailed and proper experiment of the project would be done by more professional industries that use these identification methods in day to day routine. Industries like mining would use these and other identification methods and intensive properties such as density to determine the purity and identity of the mined material.

Laporte-Balfour 40

Acknowledgements

The researchers would like to acknowledge certain people for their assistance, guidance and support throughout their research, through them the information in this paper was made possible.

First, the authors would like to thank Mrs. Hilliard for supporting and providing materials for their research, guidance in proper measurement techniques and background knowledge of the experiments, and for proofreading sections of their paper for scientific errors.

Secondly, they would also like to thank Mrs. Dewey for technical details regarding the formulation, requirements and validity of using a two sample t test.

They would also like to thank her for her advice in the direction of the project and for carefully proofreading the mathematical portions of the research.

Third, the authors would like to thank Mr. Supal for his assistance in the construction of the calorimeters as well as providing the thermal expansion apparatus for the research, and also for proofreading various sections of the paper.

Finally both authors would like to thank their families for their support mentally, emotional, and on rare occasions financial for all they have done to assist in making this research possible. Acknowledgement should also be given to researchers fellow classmates in their insight and comments throughout the completion of the work.

Laporte-Balfour 41

Appendix A Specific Heat Sample Calculation

𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝑜𝑓 𝑅𝑜𝑑 =

(𝑆𝑝𝑒𝑐𝑖𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝑜𝑓 𝑊𝑎𝑡𝑒𝑟 ∗𝑀𝑎𝑠𝑠 𝑜𝑓 𝑊𝑎𝑡𝑒𝑟∗𝑐ℎ𝑎𝑛𝑔𝑒 𝑖𝑛 𝑤𝑎𝑡𝑒𝑟

′

(𝑚𝑎𝑠𝑠 𝑜𝑓 𝑟𝑜𝑑 𝑠𝑎𝑚𝑝𝑙𝑒∗𝑐ℎ𝑎𝑛𝑔𝑒 𝑖𝑛 𝑟𝑜𝑑 ′ 𝑠 𝑇𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒) 𝑠𝑡𝑒𝑚𝑝𝑒𝑟𝑎𝑡𝑢𝑟𝑒)

The above formula can be simplified into the one below.

𝑆𝑝𝑒𝑐𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝑜𝑓 𝑅𝑜𝑑 ( J/g ∗ °C) =

𝑆

1

(J/g ∗ °C) ∗ 𝑀

1

(𝐺𝑟𝑎𝑚𝑠) ∗ ∆𝑇

1

(°C)

𝑀

2

(𝐺𝑟𝑎𝑚𝑠) ∗ ∆𝑇

2

(°C)

The equation above was used to calculate the specific heat of the metal samples.

𝑆𝑝𝑒𝑐𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝑜𝑓 𝑅𝑜𝑑( J/g ∗ °C) =

4.184( J/g ∗ °C) ∗ 20.00(𝐺) ∗ 5.00

(°C)

80(𝑔) ∗ 60.00

(°C)

𝑆𝑝𝑒𝑐𝑓𝑖𝑐 𝐻𝑒𝑎𝑡 𝑜𝑓 𝑅𝑜𝑑 = 0.087( J/g ∗ °C)

Figure 16. Specific Heat Sample Calculation

Figure 16 shows the specific heat calculation when the values for mass, change in temperature, and specific heat of water are put in.

Laporte-Balfour 42

Appendix B Thermal Expansion Sample Calculation 𝑎(°𝐶 −1 ) =

(𝐿 𝑖

∆𝐿(𝑚𝑚)

(𝑚𝑚) ∗ ∆𝑇(°𝐶)

Shown above is the formula used to calculate

“a” the coefficient of the linear thermal expansion of the rod samples. 𝑎(°𝐶 −1 ) =

0.02(𝑚𝑚)

130(𝑚𝑚) ∗ 75(°𝐶) 𝑎(°𝐶 −1 ) = 2.222 ∗ 10 −6

Figure 17. Linear Thermal Expansion Sample Calculation

Shown in figure 17 is a sample calculation of the method used to find the coefficient of thermal expansion in the research. The coefficient of linear thermal expansion is in inverse degrees celcius.

Laporte-Balfour 43

Appendix C Randomizing using TI Nspire CX Calculator

1.

Assign the two sample rods to rod “a” or 1, and the other rod to rod “b” or

2.

2. Turn on Ti Nspire calculator and open a new calculator sheet.

3. Press menu, probability, random, integer.

4. Type 1,2,15 into the random integer formula as shown in figure 16, press enter. This tells the calculator to pick an integer of either 1 or 2 and 15 separate times.

Figure 18. Ti Nspire Calculator Random Integer Function

Figure 18 shows the function that was used to randomize the trials in the specific heat and thermal expansion experiments.

Laporte-Balfour 44

Appendix D How to Operate the Logger-Pro

1. Plugging the logger pro into an outlet to keep fully charged during trials.

2. Attached two thermometer probes

3. Preset timer to 180 seconds, go to settings, menu and set the time to 180 seconds.

4. To start recording data, click on the green arrowhead. To pause or stop the collection of data, click the red square.

5. Once data has been collected, insert a flash drive into a port on the side of the logger pro. Go to the save options menu and save the data onto the specified flash drive.

Laporte-Balfour 45

Appendix E Calorimeter Construction

Materials:

(4) 1 Inch Wide PVC Piping

(4) ¼ Inch Wide PVC Piping

(4) ¼ Inch PVC Screw-Caps

(4) ¼ Inch PVC Push Caps

Chop Saw

Procedure:

PVC Pipe ¾ Inches Thick Insulation

PVC Cement

Duct Tape

Hand Saw

1. Cut the outer PVC pipe, inner PVC pipe and insulation into approximately four one-foot sections using a hand saw. A chop saw can be used as well for a cleaner cut.

2. Use PVC cement to seal the top screw-cap and the bottom cap to the inner tube.

3. Wrap PVC insulation around the inner ¼ inch PVC tube.

4. Use duct tape to secure insulation to inner tube by wrapping the duct tape around the insulation tightly.

5. Drill a hole into the top screw-on cap.

6. Place the inner tube that is wrapped in insulation inside of the outer tube and screw on the cap.

Laporte-Balfour 46

Figure 19. Completed Calorimeter

Figure 19 shows the completed calorimeter. Duct tape and PVC were used because they are good insulators (

“Tapes, Adhesives, and More”).

Laporte-Balfour 47

Appendix F: Sample calculation of Percent Error

𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝐸𝑟𝑟𝑜𝑟 =

𝐸𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡𝑎𝑙 𝑉𝑎𝑙𝑢𝑒 − 𝑇𝑟𝑢𝑒 𝑉𝑎𝑙𝑢𝑒

𝑇𝑟𝑢𝑒 𝑉𝑎𝑙𝑢𝑒

The equation above was used to calculate percent error for each trial.

Sample Calculation:

𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝐸𝑟𝑟𝑜𝑟 =

0.047 − 0.134

0.134

𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝐸𝑟𝑟𝑜𝑟 = 65%

Figure 20. Percent Error Sample Calculation

Figure 20 shows the way in which the researchers calculated the percent error for each trial.

Laporte-Balfour 48

Appendix G: Sample Calculation for Two-Sample t Test 𝑠𝑎𝑚𝑝𝑙𝑒 𝑚𝑒𝑎𝑛 𝑡 𝑠𝑐𝑜𝑟𝑒 =

√

𝑓𝑖𝑟𝑠𝑡 𝑠𝑡𝑎𝑛𝑑𝑎𝑟𝑑 𝑑𝑒𝑣𝑖𝑎𝑡𝑖𝑜𝑛 2 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑟𝑖𝑎𝑙𝑠

1

1

− 𝑠𝑎𝑚𝑝𝑙𝑒 𝑚𝑒𝑎𝑛

2

+ 𝑠𝑒𝑐𝑜𝑛𝑑 𝑠𝑡𝑎𝑛𝑑𝑎𝑟𝑑 𝑑𝑒𝑣𝑖𝑎𝑡𝑖𝑜𝑛 𝑛𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑟𝑖𝑎𝑙𝑠

2

2

The equation above was used to calculate the t score of the specific heat and thermal expansion trials. 𝑡 𝑠𝑐𝑜𝑟𝑒 =

0.000003 − 0.000002

√0.0000008

15

+

0.0000009

15 𝑡 𝑠𝑐𝑜𝑟𝑒 = 4.85

Figure 21. Two Sample t Test Sample Calculation

In figure 21 a sample calculation of how the t value was found is shown.

When the numbers were plugged in, the result was a t value of approximately

4.85.

Laporte-Balfour 49

Works Cited

"AQA A Level Chemistry - AS Unit 2: Section 3.2.7 Extraction of Metals - Principles of

Metal Extraction." AQA A Level Chemistry - AS Unit 2: Section 3.2.7 Extraction of

Metals - Principles of Metal Extraction . N.p., n.d. Web. 22 Mar. 2013.

<http://alevelchem.com/aqa_a_level_chemistry/unit3.2/sub3207/01.htm>.

"Chemistry Explained." Tungsten, Chemical Element . Advameg Inc, n.d. Web. 22 Mar.

2013. <http://www.chemistryexplained.com/elements/T-Z/Tungsten.html>.

Clark, Jim. "Extraction of Tungsten." Extraction of Tungsten . N.p., 2009. Web. 22 Mar.

2013. <http://www.chemguide.co.uk/inorganic/extraction/tungsten.html>.

"Coefficients of Linear Thermal Expansion." Engineeringtoolbox.com

. N.p., n.d. Web. 23

Mar. 2013. <http://www.engineeringtoolbox.com/linear-expansion-coefficientsd_95.html>.

"Linear Coefficient of Thermal Expansion." Ndt-ed.org

. Nondescructive Testing, n.d.

Web. 22 Mar. 2013. <http://www.ndt-ed.org/AboutNDT/aboutndt.htm>.

Litherland, Neal. "How Is Tungsten Obtained?" EHow . Demand Media, 22 Apr. 2009.

Web. 21 Mar. 2013. <http://www.ehow.com/how-does_4928752_how-tungstenobtained.html>.

Smithells, Colin J. "Tungsten a Treatise on Its Meallurgy, Properties and

Applications." Library.wisc.edu

. D. Van Nostrand Company, 16 July 1937. Web.

22 Mar. 2013. <http://www.library.wisc.edu/selectedtocs/ca758.pdf>.

"Step-by-step." Instructables.com

. N.p., n.d. Web. 22 Mar. 2013.

<http://www.instructables.com/id/How-to-Weld-TIG/>.

"TUNGSTEN MINING & BENEFICIATION." Itia.info.html

. International Tungsten

Industry Association, n.d. Web. 22 Mar. 2013. <http://www.itia.info/miningbeneficiation.html>.

Laporte-Balfour 50

"Tungsten-Mining." Great Mining.com

. N.p., n.d. Web. 22 Mar. 2013.

<http://www.greatmining.com/tungsten.html>.

"Tungsten-processing." Itia.info

. International Tungsten Industry Association, n.d. Web.

22 Mar. 2013. <http://www.itia.info/tungsten-processing.html>.

"What Are the Chemical Element Tungsten's Physical

Properties?" w ww.sciencedaily.com

. N.p., n.d. Web. 22 Mar. 2013.

<http://chemical-elements.sciencedaily.com/q/102/7956/What-are-the-chemicalelement-Tungsten-s-physical-properties>.

"Tapes, Adhesives, and More" expressinsulation.com. N.p., n.d. Web. 18 May 2013.

<http://expressinsulation.com/tapes_and_accessories.html>.