Captain Mattingly's MARMC Presentation

advertisement

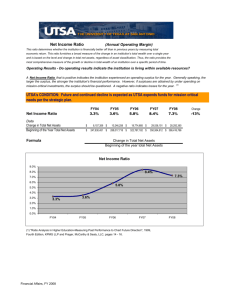

MARMC VSRA Brief 20 January, 2009 CAPT Scott Mattingly MARMC: Mission/Vision MISSION: Deliver cost-wise readiness to the War Fighters worldwide by providing industrial, engineering, technical and contracting services for maintenance and modernization of naval ships and craft. VISION: “First in maintaining global Force readiness” 2 Align w CDR RMCs Strategic Planning Session • FY09 Goals – Comprehensive mentorship program. – Change culture in Maintenance Teams to use meaningful metrics (vice reactionary). – Build symbiotic relationship with CLASSRONS. – Achieve contract output “consensus” to deliver expected value to Warfighters. – (Note: To align under NAVSEA 04 in CY09) EXCEED THE CUSTOMER’S EXPECTATIONS 3 Warfighting now & then.. What statement has been used by both General Custer and Al-Quaida terrorists? 1. One if by land and two if by sea. 2. Damn the torpedoes, full speed ahead. 3. Where are all those tomahawks coming from? 4 What is “READINESS”?? DVD Show 5 MARMC & VSRA => Service to the Fleet • Surface / Air / Sub TYCOMs – 65+ Surface Ships (All Ship Classes!) – 6 Aircraft Carriers – 12 Submarines • Coverage ~Global – 2nd, 5th and 6th Fleets • Global Distance Support (Tech Assist) 6 MARMC CASH-Management.. (NOT all in Tidewater region) How much private sector work did MARMC manage for the Navy in FY08? 1) $565M 2) $1.63B 3) $891M 7 MARMC FY 08 FUNDING $891,733,715 Grand Total Funding (FY-to-date) REIMB (YTD) $21,439,271 2% RESOURCE SPONSOR 4BML $0 0% B&M $17,383,374 2% ~60% Surface Maintenance ENVIRONMENTAL 5BEC $307,000 0% MISSION SUPPORT 4BML $121,447,394 14% SWE (Active) 4BRA $380,253,006 43% NAVSEA PROJECT DIRECTIVES $152,587,425 17% NAE (ROV) 4BML $2,502,025 0% DIRECT CITES YTD $90,497,835 10% SWE (ROV) 4BML 6,844,006 1% NAE (Active) 4BRA $51,146,196 6% Data Date: 30 September 08 Data Source: Code 650, NEMAIS, STARS, Code 640 USE (ROV) 4BML $3,040,720 0% USE (Active) 4BRA $44,285,464 5% 8 Navy Vessel Count FY04 - FY09 70 # Homeported in Norfolk 60 50 40 30 20 10 0 FY04 FY05 FY06 SURFACE Prepared By: Financial Analysis Division - Code 650 [DJS] FY07 SUBMARINE FY08 FY09 FY10 CARRIER Report Date: 01/14/2009 10 MARMC’s Norfolk Footprint 5 1 CEP-200 2 CEP-209 3 LF-18 4 V-58 5 X-70 11 MARMC’s Global Footprint 40,000 square mile AOR 12 MARMC Det. Naples FTA Metrics MARMC NAPLES DET BI-WEEKLY PRODUCTION REPORT TASKING SUMMARY ACTIVE TASKS SUMMARY # OF TASKS 80 60 40 ONBD, 13, 5% 64 RTHP, 28, 11% DSIP, 88, 35% 44 20 0 APTS, 126, 49% COMP DSIP 5 COMP ONBD NEW TASK 90 80 # OF TASKS 70 60 50 40 30 20 10 0 7 1 4 8 2 6 /3 /1 /3 /1 /2 /1 /2 10 10 10 11 11 12 12 9 1/ 23 1/ 6 2/ 20 2/ 5 3/ 19 3/ 2 4/ 16 4/ 30 4/ 14 5/ 28 5/ 11 6/ 25 6/ 9 7/ 23 7/ 6 8/ 20 8/ 3 9/ 17 9/ /1 10 FY-08 APTS = AWAITING PARTS COMP = COMPLETED DSIP = DISTANCE SUPPORT ONBD = ON BOARD ASSIST RTHP = RETURN TO HOMEPORT COMP DSIP COMP ONBD NEW TASK = 1000+ FTA events/year at both Dets 13 BRAC Challenge Round !! BRAC law stipulates which of the following for MARMC’s future? 1. The I-level facility/capability previously at MARMC must consolidate into NNSY by FY2010. 2. All of MARMC must consolidate with NNSY by FY2010. 14 NNSY I-Level Organization Ship Yard Commander C100 Deputy Commander C100B Fleet Maintenance Submarine (FMB) Fleet Maintenance Surface (FMR) Combatant Fleet Maintenance Shops (FMS) CVN Each division includes personnel and capabilities from various Shops and NNSY Codes (PEPM, BSBO, Resource Managers, etc.) to carry out Intermediate Maintenance. 15 Missions: “MARMC”: Now and Future… • Missions now: – 1) “Manage” All regional private sector depot work. – 2) C.O. for Fwd Dets & USS DYNAMIC DD – 3) Fleet Technical Assistance(FTA) and support to Fleet assets in 2nd, 6th and 5th Flts. • “New MARMC” FY10: – 1) “Manage” All regional private sector depot work. – 2) C.O. for Fwd Dets & DYNAMIC DD – 3) Fleet Technical Assistance (FTA) to Fleet assets in 2nd, 6th and 5th Flts. 16 Who is MARMC? 17 MARMC Today… COMMANDING OFFICER Det Naples Det Bahrain USS Dynamic, Drydock (AFDL-6) X.O. (C300) ENVIRONMENTAL/ SAFETY 106 ENGINEERING/ TECH SERVICES (NAVSEA Warrant) 200 FINANCIAL 600 EXECUTIVE DIRECTOR WATERFRONT OPERATIONS 300(Mil) COMMAND SUPPORT SVCS 1100 CONTRACTS (NAVSEA Warrant) 400(Mil) LOGISTICS (Fleet Industrial Supply Center) 500 Mil BUSINESS DEPARTMENT 1200 18 (Name TBD) Organization “Target” on Oct 09 C.O. X.O.? EXECUTIVE DIRECTOR NNSY ENVIRONMENTAL/ SAFETY 106 Det Naples Det Bahrain USS Dynamic, Drydock (AFDL-6) NNSY ENGINEERING/ TECH SERVICES 200 (Partial) MARMC WATERFRONT OPERATIONS 300(Mil) MARMC CONTRACTS FISC LOGISTICS 400(Mil) 500(Mil) NNSY FINANCIAL NNSY COMMAND SUPPORT SVCS 1100 NNSY BUSINESS DEPARTMENT 1200 600 19 MARMC PRIVATE SECTOR WORKLOAD: “Leveling” efforts (Oct 2008 – Sep 2012) 6000 P r o d u c t i v e FY-09 5000 FY-10 MARMC OBTAINING SBS TALENT FROM NNSY & CONTRACTED SUPPORT TO COVER PEAK WORKLOAD IN FY09 FY-11 FY-12 BLUE LINE INDICATES ORIGINAL WORKLOAD TOTAL PORT PRODUCTIVE MPD AVAILABLE (3660 based on 3 year avg) FR EED OM 4000 A S H LA N D M 3000 P D P OR TER B U LK ELEY C OLE FOR T M C H EN R Y B A TA A N R 2000 e q u i 1000 r e d LA B OON C H U R C H I LL K EA R S A R GE C OOK N OR M A N D Y A N ZI O BARRY M ON TER EY CM LE GE ND CNO A V A I LS SHI FT E D A V A I LS S M A LL B OA TS / LC A C s ( i nc l ude s P ROP OSE D SHI FT S LEP s) 0 O N D J F M A M J J A S O N D J F M A M J J A S O N D J F M A M J J A S O N D J F M A M J J A S O Data date: 01 Dec 2008 Prepared by: C-1250 Data source: SEA 04XF2 and C-1250 20 Why MSMO? • Navy operating concept: Fleet Response Plan (FRP) – Rotational and surgeable – Improved AO (LSDs currently have highest AO since commissioning!) – Ops sked uncertainty requires different supporting maintenance concept. • Old maint business model does not support surge readiness or AO – Navy needed a continuous, responsive, accessible, flexible, affordable, 24/7 maintenance delivery process. • MSMO is that process. – MSMO delivers maintenance more reliably and continuously, and reduces the readiness “bath tub” effect in a rapidly changing and dynamic environment. • MILPERS Reduction Initiative instituted in FY08 relied in part on MSMO contractors as a key source for that workload accomplishment. 21 MSMO Outcomes • MSMO demonstrates that it supports AO and surge readiness – “Nearly all” MSMO CNO avails complete on time – CMAVs have reduced material readiness “bath tub” effect – Emergent response has been very successful: • MANY examples….. – Technical performance Outstanding • No documented operational/mission degrading failures due to MSMO workmanship. – Learning Curve performance • Class familiarity permits production engineering improvements and maintenance innovations • Shaft repairs, Docking costs, MV-22, All-electric upgrade, Hab Mods, Scan Eagle, Rapid Cure Coating, Rudder seal replacements, etc…. • MSMO Cost: Nearly all availabilities perform under the original negotiated cost • More and more partnering evident 22 Contract Status Awarded Contracts Homeport/Class Awarded Contract Number Awardee Norfolk DDG Docking Norfolk DDG (Non Docking) Mayport DDG (Non Docking) Norfolk LHA/LHD San Diego CG Ingleside TX (MCM 1 Class) Puget Sound (FFG/DDG) San Diego LPD/LSD Norfolk LPD/LSD Non Docking Norfolk FFG 7 Norfolk CG 47 Pearl Harbor DDG/FFG/CG San Diego LHA/LHD San Diego DDG Mayport FFG 7 San Diego FFG 7 Norfolk LSD Midlife San Diego MCM San Diego LSD 41 Docker 20 December 2004 15 February 2005 15 February 2005 23 December 2004 24 March 2005 18 July 2005 19 September 2005 5 December 2005 22 December 2005 26 April 2006 17 May 2006 13 September 2006 29 January 2007 26 March 2007 12 July 2007 03 August 2007 28 January 2008 14 May 2008 03 July 2008 N00024-05-C-4404 N00024-05-C-4406 N00024-05-C-4413 N00024-05-C-4403 N00024-05-C-4409 N00024-05-C-2304 N00024-00-C-8514 N00024-06-C-4402 N00024-06-C-4401 N00024-06-C-4412 N00024-06-C-4415 N00024-06-C-4408 N00024-07-C-4013 N00024-07-C-4407 N00024-07-C-4413 N00024-07-C-4415 N00024-08-C-4406 N00024-08-C-4405 N00024-08-C-4410 NORSHIPCO (Now BAE-N) MHI MHI NORSHIPCO (Now BAE-N) SWM (Now BAE-SD) ANTEON (Now GDIT) Todd Pacific Shipyard NASSCO Earl Industries (Protested) METRO (Protested) BAE Norfolk BAE Hawaii NASSCO BAE MHI/TECHNICO JV (Protested) NASSCO METRO (Protested) BAE SD NASSCO 23 Change Management … We LOVE IT! • "What I need is an exact list of specific unknown problems we might encounter." – (Lykes Lines Shipping) • "This project is so important we can't let things that are more important interfere with it.“ – (Advertising/Marketing mgr, UPS) • "We know that communication is a problem, but the company is not going to discuss it with the employees." – (Switching spvsr, AT&T Long Lines Division) 24 Questions ??? 25 NNSY/MARMC Capability / Divestment Plan Divest to Ktrs (MSMO, IDIQ, etc) Sheet Metal fabrication/repairs (NOV 07) Wire Rope and Nylon Safety Nets (MAR 07) Lagging Shop (Aug 07) Small Boat repair (Sep 07) Carpenter Shop (OCT 06) 2M Repair (Nov 07) Radome Repair (Oct 08) External Comms (Oct 09) IC Repair (Dec 08) SISCAL (NSWC) NNSY FM Shops (were RRCs) Diesel engine repair / Governor Test/Repair Pump overhaul Motor overhaul * Life raft * CIWS & 25mm Dive locker * Regional Cal Lab NNSY I- Level Capabilities Surface (FMR): Submarine (FMB): Watertight Door Ship/Pipe Fitters * Gas Turbine Repair Outside Electric, cable way Heat exchanger repair Inside machine Flex Hose Shop AC/R Outside Machine/hydraulic Lock and Key * Fleet Tool Issue Engraving Rigging/Weight Test Valve Repair Hull repair Welding Pipe shop Outside electric Inside machine AC/R Acoustic Rubber & Plastics Combat Controls Hydraulics Blue text and * indicates Sole Source Capability provider. 26 BRAC Challenge Round #2! Regarding the BRAC Consolidation, who said? "No one will believe you solved this problem in one day! We've been working on it for months. Now go act busy for a few weeks and I'll let you know when it's time to tell them." 1) CAPT Rick Berkey 2) CAPT Scott Mattingly 3) R&D supervisor, Minnesota Mining and Manufacturing/3M 27 MARMC Goal Enablers (How To) • Communications – We are open and honest at all times. • Value People – Build trust. Emphasize both personal and professional development. • Continuously strive to improve – Our country is at war and demands we perform at our best while getting better!! 28 Maintenance Team • • • • • Ship’s Commanding Officer MARMC Port Engineer (PE) Ship Maintenance Material Officer Maintenance, Modernization & Material Coordinator Norfolk Naval Shipyard-Intermediate Maintenance Facility Ship Superintendent • Regional Maintenance Center Type Desk Assistant • MARMC Project Manager • Additional Ships Company (CO’s Discretion) 29 Maintenance Team’s Primary Responsibilities • Identify and prioritize work requirements clearly and accurately – Determine when and where work will be accomplished – Match resources to requirements – Manage all ship availabilities – Budget responsibility – Execute Modernization at TYCOM direction 30 Back-Up Slides 31 Surface 70 # Homeported in Norfolk 60 50 40 30 20 10 0 FY04 FY05 FY06 FY07 FY08 FY09 FY10 FY Surface 700M 600M 500M 400M 300M 200M 100M 0M FY04 FY05 FY06 FY07 MODERNIZATION Prepared By: Financial Analysis Division - Code 650 [DJS] FY08 FY09 FY10 REPAIR Report Generated Date: 1/14/2009 Submarines 16 # Homeported in Norfolk 14 12 11 9 7 5 4 2 0 FY04 FY05 FY06 FY07 FY08 FY09 FY10 FY Submarines 70M 60M 50M 40M 30M 20M 10M 0M FY04 FY05 FY06 FY07 MODERNIZATION FY08 FY09 FY10 REPAIR 33 Carriers 8 # Homeported in Norfolk 7 6 5 4 3 2 1 0 FY04 FY05 FY06 FY07 FY08 FY09 FY10 FY Carriers 100M 80M 60M 40M 20M 0M FY04 FY05 FY06 FY07 MODERNIZATION FY08 FY09 FY10 REPAIR 34