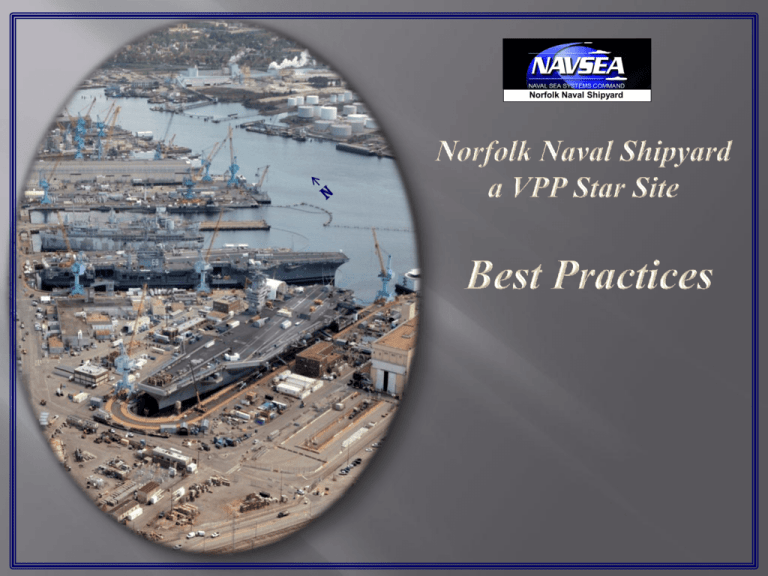

Norfolk Naval Shipyard

advertisement

Norfolk Naval Shipyard - Introductions Four Flags Gate 2 Kicked off VPP in 2003 VPP STAR recognition in 2006 50 % decrease in TCIR since 2003 Three year VPP Star recertification in July 2009 2nd recertification in April 2014 Presented the Chief of Naval Operations (CNO) Safety Award and the Secretary of the Navy (SECNAV) Safety Award in 2014 for Large Industrial Category Full Service Waterfront Support • 5 Drydocks (1 Service Dock) • • • • Only Military CVN East Coast Drydock 3 Major Servicing Piers East Coast SSBN Refueling Mission CVN, LHD, SSBN, SSGN, SSN, LPDs, Surface Ships, Tenders Fully Capable Depot Maintenance Plant • Full Service Shipyard • Component Repair Operating Profile • 1.5 Million Man Days Per Year • Annual Business $1.2 Billion • 9,500 Civilians & Military Fleet Support • Industrial Support Area for Ship’s Force • • • • MWR, NEX, Commissary, Gym CDC, Housing Areas Fleet Training Center Fleet Berthing Support 4 Tidewater Virginia Metal Trades Council (MTC) American Federation of Government Employees (AFGE) – Local 22 American Federation of Government Employees (AFGE) – Local 4015 International Federation of Professional and Technical Engineers (IFPTE) – Local #1 – (two units). 2 Bright Ideas/Rapid Prototype Lab Center Communities of Practice High Risk Teams Continuous Training Development Job Readiness Cells Core Work Groups 3 Bright Ideas Group is a successful program implemented by the Metal Trades Council Union to improve performance at NNSY. They turn the employees idea into reality The employees Bright Ideas are submitted to the Rapid Prototype Lab Center (RPLC) which is a core team of mechanics with varied industrial trade skills, trained in performance improvement methodologies. The RPLC includes the unique 3D printing capability that provides three dimensional models of designed components prior to their manufacture. Most items are safety related to improve job performance. Once the prototypes are implemented the design is shared among other shipyards. Backpack Tool Bag Fire Extinguisher Backpack Zero Energy Arm Electrical Facilities Combined Welding Propulsion Plant Test One of the NNSY Hazard Elimination and Control Methods are the five High Risk Teams: Electrical Fall Protection Hazardous Energy Control Confined Space Fire Prevention High Risk Teams perform surveillances, assess current trends, and develop strategies to minimize hazards or improve behavior. The Continuous Training and Development (CTD) Program concentrates on identifying critical skill sets needed to execute current and anticipated work, and maintaining or developing those needed skills. Each operations department has developed a training program to their specific trade and established a handon mock-up area. A Job Readiness Cell is an execution planning vehicle that provides “point of use” tooling, material and technical instructions to support work execution. Job Readiness Cells are designed to have the tools and equipment ready available for the employees to prevent time-wasting energy and injury seeking the materials needed. Core Work Teams (work gangs) are designed to improve employee development and sense of ownership by maintaining consistency in the work group. Enables longer-term mentoring, resulting in more efficient execution of work. Promotes employee development through peer learning and strengthening of the supervisormechanic relationship. Questions?

![[STORY ARCHIVES IMAGE]](http://s3.studylib.net/store/data/007416224_1-64c2a7011f134ef436c8487d1d0c1ae2-300x300.png)