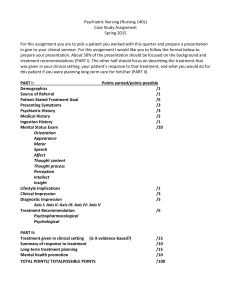

KA3-6VS 300_400 spec sheet

advertisement

30 TAPER Machine Builder CNC Module Vertical KA3-6VS 300mm KA3-6VS 400mm Vertical Spindle The Kira KA3- Series of traveling column (3) Axis CNC Machining Modules are an excellent choice for special application machine builders. These modules are designed to mount to your base. Speed: Accuracy: Reliability: Support: Fast rapids, fast tool change, high rpm Built, tested, documented and certified in Japan Uptime that exceeds any machine in the market without exception Technical support and spare parts on hand at Kira America’s facility in Wisconsin Dependability: Kira America Corporation is here for you. We have been serving North, Central and South America for over 20 years. Standard Module Includes: ● Fanuc 0i-MD Series control ● Rigid Tapping ● X Axis of 300mm or 400mm ● 1 second tool change time (T to T) ● 5HP Spindle Motor ● 30 Taper Spindles (6) Standard ● 6 Station Turret/8 Stations Optional ● (3) Configurations – Vertical ● Available in 300 or 400 “X” Axis stroke * Please refer to the following pages for available options and full machine specifications. Page 1 of 5 August 17th, 2015 30 TAPER Machine Builder CNC Module KA3-6VS Series Standard Equipment Complete set of Kira and Fanuc Manuals ························································ Standard Tool Box············································································································ Standard FANUC 0iMD CONTROL STANDARD SPECIFICATIONS 10.4 Color Monitor ································································································ Standard 1280 Meters of Memory························································································· Standard 2nd Auxiliary Function ···························································································· Standard 3RD/4th Reference Position Return ·········································································· Standard Absolute Encorders all axes ···················································································· Standard Addition of Custom Macro Common Variable ······················································· Standard Additional of Work piece Coordinate System (48 pairs) ········································ Standard Ai Advanced Preview Control (15 Block Look Ahead) ············································ Standard Automatic corner override ····················································································· Standard Automatic coordinate system setting····································································· Standard Background editing ································································································· Standard Buffer register ········································································································· Standard Canned cycles for drilling ························································································ Standard Controlled Axes 3, 5 maximum ··············································································· Standard Conversational programming with graphic function ·············································· Standard Coordinate System Rotation ··················································································· Standard Circular interpolation by R programming ······························································· Standard Custom macro B······································································································ Standard Cutter compensation C (G40-G42) ········································································· Standard Dwell (G04) ············································································································· Standard E-Stop ······················································································································ Standard Embedded Ethernet ································································································ Standard Extended Part Program Editing ·············································································· Standard External Data Input ································································································· Standard External Deceleration ····························································································· Standard External I/O Device Control ···················································································· Standard External Machine Zero Point Shift ·········································································· Standard External Message ···································································································· Standard External Tool Offset ································································································ Standard Frequency (60Hz) ····························································································· Standard Feed rate override switch ················································································ Standard Graphic Function ······························································································ Standard Helical Interpolation ························································································ Standard High Speed Skip ································································································ Standard HRV (High Response Vector) ············································································ Standard Inch/Metric Conversion ··················································································· Standard Interruption type custom macro ····································································· Standard Language on the operation panel (English) ····················································· Standard Page 2 of 5 August 17th, 2015 30 TAPER Machine Builder CNC Module KA3-6VS Series Fanuc 0i-MD Standard Features (Continued) Least input increment (0.001 mm) ·································································· Standard Linear acc/dec after cut feed interpolation ····················································· Standard Linear acceleration/deceleration after cutting feed interpolation ················· Standard Linear Interpolation (G01) ··············································································· Standard Manual handle interruption ············································································ Standard Mirror image ···································································································· Standard Optional block skip (9) ····················································································· Standard Optional chamfering/corner R ········································································· Standard Pattern data input ···························································································· Standard PCMCIA Card Slot ····························································································· Standard Playback ··········································································································· Standard Polar Coordinate Command············································································· Standard Position Switch ································································································· Standard Positioning (G00)······························································································ Standard Program number display: 4 digits ···································································· Standard Program number search ·················································································· Standard Program Restart ······························································································· Standard Programmable Data Input (G10)······································································ Standard Programmable Mirror Image ··········································································· Standard Registered Programs 400 ················································································· Standard Retraction for Rigid Tapping ············································································ Standard Rigid Tapping ···································································································· Standard RS232 Port········································································································ Standard Run Hour Parts Count Display ·········································································· Standard Scaling ·············································································································· Standard Self-diagnosis function ····················································································· Standard Sequence number display: 4 digits ·································································· Standard Sequence number search ················································································ Standard Simultaneous Axis Expansion (3 Axis Simultaneous) ······································· Standard Single Direction of Spindle Orientation ··························································· Standard Small Hole Peck Drilling Cycle ·········································································· Standard Spindle Analog Output ····················································································· Standard Spindle Orientation ·························································································· Standard Software Operator’s Panel ··············································································· Standard Stored Pitch error compensation····································································· Standard Stored Stroke Check 1 ······················································································ Standard Stored Stroke Check 2, 3 ·················································································· Standard Tool Length Measurement··············································································· Standard Tool offset: 32 pcs. ··························································································· Standard Unexpected Disturbance Torque Detection ···················································· Standard Work coordinate system (G52-G59) ································································ Standard Page 3 of 5 August 17th, 2015 30 TAPER Machine Builder CNC Module Service Requirements – Electrics Supply (input) KA3-6VS Series Structure ············································································································ 3-phase Cycles ····················································································································· 60 Hz Power ·················································································································· 11 KVA Voltage ········································································································200-220 volt NOTE: Other voltages require an external transformer Compressed Air (Pressure Flow) ··········································································· 60 psi Cycles ··············································································································· Standard Power ··············································································································· Standard Space Requirements Floor Space ······················································································· Consult CAD layout Weight ············································································································· 6,000 lbs. Travel X axis stroke Y axis stroke Z axis stroke KA3-6V 300mm 11.8" (300mm) 9.8" (250mm) 11.8" (300mm) KA3-6V 400m 15.7” (400mm) 9.8” (250mm) 11.8” (300mm) Spindle Power 8,000 RPM - 5HP ···························································································· Standard 4,000 RPM - 5HP ····························································································· Optional 10,000 RPM - 5HP ··························································································· Optional Feed Rate – Rapid traverse/Cutting feed rate X axis ························································· 954 IPM (24,000mm)/394 IPM (10,000mm) Y axis·························································· 954 IPM (24,000mm)/394 IPM (10,000mm) Z axis·························································· 954 IPM (24,000mm)/394 IPM (10,000mm) Tool Shank Standard ·················································································································· BT30 Tool Changer Number of tools ···················································································· 6(Option 4 or 6) Tool change time (T-T) ························································································· 1.0 sec Tool change time (C-C) ························································································· 3.0 sec Maximum tool diameter ··········································································3.9” (100 mm) Maximum tool length ··············································································7.9” (200 mm) Maximum tool weight ·················································································6.6 lbs (3 kg) Accuracy Positioning accuracy (X, Y & Z) ························································· 0.0002 (0.005 mm) Positioning repeatability (X, Y & Z axis) ········································±0.0001” (0.003 mm) Page 4 of 5 August 17th, 2015 30 TAPER Machine Builder CNC Module KA3-6VS Series Machine Optional Features - CONSULT KIRA AMERICA FOR OPTION PRICING 30 Tools Vertical Machines Only Additional M function (more than 5 pcs per 1 pc) (Factory Installed Only) Additional set of manuals (Kira and Fanuc) Air Blast CE Mark specification (For European market) CSA electric parts (Canada) Must specify which components apply DNC select switch Electric cabinet cooler Light in the electrical cabinet Machine special color (up to two colors) Oil Mist (air mist), unit mounted to lubricate tool Outside P.C. preparation Short circuit breaker Tool Breakage Detection – Electric wand mounted on column (Retrofitted) Tool Breakage Detection system with 5m cable (push type) Transformer Spindle Options 10,000 RPM (belt) with spindle cooling system 4,000 RPM (belt Fanuc Oi-MD CNC Control Options Part Program Length 2560m AI Contour Control (AICC) 40 block Look Ahead Data Server (Factory Orders Only) 1GB ATA Flash Card (Data Server must be installed at factory, no retrofit. Select one from your choice of 3 below) ● Data Server Software (S737) (Factory Install Only) ● Data Server Software (J561#658W) (Factory Install Only) ● Data Server Editing Function (R643) (Factory Install Only) Two Additional Axis, 5 Axis Machining (6 Axis Servo Card Required) Manual Guide I Manual Guide 0i (no graphics) Fanuc Tool Life Management (TLM) – cannot be used with Kira TLM Kira Tool Life Management (TLM) – cannot be used with Fanuc TLM Page 5 of 5 August 17th, 2015