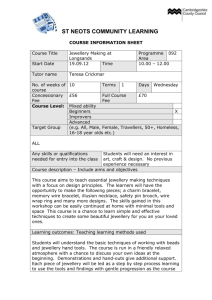

for the Jewellery Manufacturing units

advertisement

1 GJEPC has added significant value to the industry over the last 5 decades… Vision statement “ To make India the preferred source for quality gems and Jewellery” Key comments • completed Set-up in 1966, the GJEPC has 49 years Mission statement • Target value addition US $ 5 billion “To enable every individual associated with the Indian gems and Jewellery industry to achieve their full potential” • Target to employ 1 million workers for exports 2 GROSS EXPORTS OF GEMS & JEWELLERY DURING 2014 - 2015 Mumbai Other Ports % Share of % Share of Other Mumbai in Total Ports in Total Exports Exports Total 2014 - 15 US$ Mill US$ Mill US$ Mill % % C & P Diamonds 22751.41 408.67 23160.08 98.24 1.76 Col. Gemstones 18.98 434.26 453.24 4.19 95.81 Gold Jewellery 3093.79 6809.72 9903.51 31.24 68.76 Other Items 1260.00 5250.98 6510.98 19.35 80.65 27124.18 12903.63 40027.81 67.76 32.24 Total Exports Other Items include Pearls, Silver Jewellery, Gold medallion, rough diamonds, synthetic stones, costume jewellery, sales to foreign tourists. 3 MANPOWER REQUIREMENT IN THE GEM & JEWELLERY INDUSTRY • Based on the study conducted by IMRB International, it was estimated that the gems and jewellery industry employed approximately 34 lakh people across various segments including Diamond and Gemstone Processing, Jewellery Manufacturing, Retailers, Traders, Wholesalers etc. Segment Current Manpower Gemstone processing units: ~ 1.65 lakhs Diamond processing units: ~ 7 to 8 lakhs Jewellery manufacturing units: ~ 15 lakhs Jewellery retailers: ~ 11 to 11.50 lakhs (traders, wholesalers etc.) ~ 3 lakhs Miscellaneous (Brokers) ~ 1 lakhs Total ~ 41 lakhs 4 Functional distribution of human resources across the jewellery fabrication segment through machinery Function Distribution Percentage (%) Design 5% Manufacturing 70% Marketing 10% HR, Admin 5% Finance Allied Support 3% 3% 4% Functional distribution of human resources across the jewellery through Handmade Function Distribution Percentage (%) Workers( Karigars) 75% Supporting Staff 10% Polishing 10% Mina Kari/Engravers 5% 5 Artisans/Workers in Jewellery Industry In 1980 Mumbai Workers/Artisans 50,000 Surat Workers/Artisans 250,000 In 1990 Mumbai Workers/Artisans Over 100,000 Surat Workers/Artisans Half a Million The sludge is washed and cleaned with water to remove mud and granules Now Mumbai Workers/Artisans 25,000 Gujarat Workers/Artisans 800,000 Requirement for creation of a Manufacturing Zone for Jewellery by Maharashtra Govt. in proximity of Mumbai with all amenities. 6 NEED FOR EXPANSION & RELOCATION 7 Locational Benefit • Close to new international airport; • Availability of Metro connectivity in a approachable distance; • Nava Shiva link road (duck to Belapur) will reduce the travel time to the location; • CIDCO is developing new Business Park like BDB. So a better infrastructure for transport as well as the other basic requirement will be ready available; • Better connectivity from South-Mumbai, BKC, Borovilli ( travel time is only 1 to 1.15 hr); • Fully developed IT-Sectors around the location; • 3 star and 5 star hotels already in functional; • Affordable housing facilities available for karigaras and employees in a 2 to 5 kms periphery; • Schools and hospital aviable in approachable distance; • Just 2 Kms away from Ghonsoli railway station; 8 Benefit of Conducive Working Environment 1. Single window clearance for all permission 2. The crowded sweatshops Room is 10 feet by 12 feet & workers spends approximately 12 hours a day, bent over a saddle-shaped wooden table lit dimly by a low-hung tube light which is reducing the productivity of the karigars. 3. The workplaces that hardly meet minimum requirements like space, ventilation or comfort though jewellery that finds a market across the country and is exported to other parts of the world is often crafted in. 4. Due to lack of proper infrastructure as per the labour law and other Govt. law and regulation, a regular intervention of Govt. official is slowing down the productivity; 5. The buildings are very old and thickly populated at Zaveri Bazaar. These are built in the 19th century and multistore, where there is no lift neither it is exit is easy if any mishap will happen. 6. No proper worker accommodation, no training and no other ancillary facilities like business hotel, convention centre, incubation centre etc. 7. Rental cost is high without self content units ( i.e., toilets, pantry etc) 9 Financial Benefit 1. Provision of minimum requirement of infrastructure will reduce the gold loss ratio from 10% to 5%. Because the gold dust can be recovered easily from carpets & drainage systems which is the biggest benefit for the Artisans. 2. Govt. officials’ repeated visit for verifying the infrastructure related matter will zero down; 3. By providing a comfortable working environment, productivity of the karigars will increase, which will make the product price more competent and profitability will increase; 4. Self content units will make the work place healthier, which will reduce the health issues of the karigar. by which medical expanses will reduce. “ Health is Wealth”; 5. The accident and fire hazard can be eliminated and can be also covered under accident insurance policy; 6. Provision of business centre, museum, including in Maharashtra tourism will generate more business opportunity. 10 Benefits of Ease of Doing Business We can able to avail following benefits inside the premises: 1. Common Facility Centre ( CFC’s) for the Manufacturing units 2. Training Institutes 3. Suppliers Shop( Tools & all other supporting staff) 4. Self content units (i.e., toilets) 5. Emergency Hospital 24*7 6. Cheap Electricity for Manufacturing units 7. Back-up power( 24*7 –Huge Generators ). 8. Continuous water supply for worker accommodation, manufacturing units/factories, business hotels, hospitals , Canteenetc., 9. Council Office Building & Conference Rooms for meetings 10.The employed generated for the proposed Jewellery Park is approximately 80,000 people. 11.Low cost accommodation for workers outside the park 12. 20 minutes walkable distance from Ghansoli railway 11 station. Common Facility Centre ( CFC’s) for the Jewellery Manufacturing units Design Manufacturing Export/Retail CFC’s for the Jewellery unit Refining Hallmarking Manufacturing Mina Kari Ball Making Wire Making TarPattern Die Cutting Polishing Grinding and assembly Casting Setting 12 Waxing Model and Mould Making Training Institutes GJEPC has following educational institutes offering courses in gems and jewellery in major centres for the industry in the country. With the aim of building a pool of trained manpower resources for the industry, it can be facilitated for the internship, practical training for part of the course curriculum. List of Training Institutes are as follows:1. 2. 3. 4. 5. 6. 7. The Indian Institute of Gems & Jewellery (IIGJ) Indian Diamond Institute (IDI) Gemmological Institute of India (GII) Gem Testing Laboratory, Jaipur (GTL) Indian Gemmological Institute, Delhi (IGI) The Gem & Jewellery Skill Council of India (GJSCI) Gemmological Institute of America( GIA) Few courses offered for Jewellery Making are as follows:• • • • • • • Hardworking Skills / Basic Bench Work Joining / Fabrication Techniques CAD/CAM dessigning Alloying – Ag, Au & pt. Finishing Techniques Introduction to Linking, Hinging, Clasps & Findings Introduction to Settings *Channel & invisible *Prong & pave *Bezel, flush & certain other stylized versions 13 Benefits from Government/Other regulatory Bodies 1. Reorganize as a MSME unit, because of organized unit. 2. Subside rate for electricity under the MSME business unit scheme. 3. High security, which is currently lack. 4. Uninterrupted water supply & electricity 5. Neat & Healthy Environment, which will fulfil the labour law 6. Single window clearance for all govt. rules and regulation 7. One of the biggest hubs for B2B and B2C merchandizing in future. 8. Declare as a jewellery tourist spot for the foreign tourist to promote the Indian concept/culture based 14 designs. Health Insurance Policy for Workers( Karigars) Swasthya Ratna Policy – GJEPC Initiative 1. The Gem & Jewellery Export Promotion Council (GJEPC) has introduced a Group Health Insurance Scheme (a CSR Health Insurance initiative) from March 1, 2015. This Scheme is named as Swasthya Ratna under which all GJEPC member companies can enrol employees and their families. 2. The Swasthya Ratna Health Insurance scheme is based on the approved comprehensive Mediclaim and Personal Accident Insurance policy between Gem and Jewellery Export Promotion Council (GJEPC), National Insurance Company Limited (NICL), MD India Healthcare Services (TPA) Pvt. Ltd. Edelweiss Insurance Brokers Ltd. (EIBL) is a Insurance broker to this product for which the policies will be provided by National Insurance Company Limited. 3. The council has created this scheme with different options related to family size, nature of benefits etc. to make this scheme flexible and affordable. 4. Council is contributing to the scheme by sharing 25% of the total premium amount for all GJEPC Member employees and their dependant. 15 • GJEPC’s role for the Jewellery Park 1. Coordination with Government bodies to facilitate the removal of procedural hurdles. 2. Providing & coordinating infrastructure requirements. 3. Monitoring and guidance for the any specific issues. 4. Coordination and cooperation for completion of the project. 5. One point contact for any issue. 16 17 PRODUCTION FACILITY S.No USER(No. of Users) PLOT AREA (CALCULATED CONSIDERING BUA IS 80% OF THE PLOT AREA) SFT UNITS/GALAS Cost ( In Rs) 1 Lakh (STALL SIZE AVERAGE in multiple of 500 sq.ft) ACTUAL SIZES COULD BE S.No Manufacture Units 1 Large 2 Medium 500 3 Small 300 1000 SERVICE INDUSTRY GALAS Note: Flat land is also available 18 Ancillary Buildings S.No PARTICULARS TOTAL AREA (sq.ft) 1 Canteen 3,000 2 Training Institutes 5,000 3 Jewellery Park Office 2,000 4 Common Facility Centre for the Manufacturing units Cost( In Rs) 20, 000 Model and Mould making Waxing Setting Refining Mounting Findings Casting Grinding/Assembly Finishing/Polishing 5 Emergency Hospitals 2,000 6 Shops of accessory products needed in jewellery-making 10,000 7 Water Storage 500 8 Space for Huge Generators( Electricity Back-up) 1000 9 Banks/ Nominated agencies 5,000 10 Show case of jewellery 3,000 19 Solar energy production facility to reduce the cost of energy consumption Infrastructure outside Jewellery park PLOT AREA (CALCULATED CONSIDERING BUA IS 80% OF THE PLOT AREA) S.No PARTICULARS SFT 1 2 3 Cost( In Rs) Worker Accommodation School College 20 21