Introduction

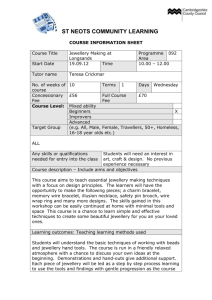

advertisement

Introduction In this project, we are going to make a tool that helping the Jewellery Box Manufacturing Company in Dongguan, China, to design and manufacture an Automated Production Line for Jewellery Box. Project aim We had a site-visit before designing the machine. It is noticed that several manpower is required to manage and standby in a production line of the jewellery box. Even a simple jewellery box would be divided into several parts of work, and each part would require manpower for that. Obviously, too much manpower is used for a simple jewellery box production. It is a wasted. Moreover, the production rate is not so high. Firstly, the aim is that the machine can make the jewellery box automatically. Furthermore, it would let company save the time of production and also the manpower. Ideally, the whole production would only require few workers and the machine instead of much manpower. Project title and brief introduction Mainly the machine would be divided into two parts. One of them is Glue filling and paper cutting, and the rest is Paper folding. In the part 1, machine is design to filling glue on the paper, and cutting the paper with the basic shape of the jewellery box (before folding). Part 2, the paper would glue the box, then it would under folding by the machine. Finally a jewellery box is made. Requirement The machine is used for the whole production line. There are some requirements on that. The production rate is required to be higher than that of using manpower. It is an automation machine. It would be a waste if the production rate is not high enough. Quality is also one of the important parts. Jewellery box is a kind of luxury product. It is required a perfect and conditional shape. Otherwise, it would ruin the jewellery. In the machine, each parts of the machine should be portable and changeable easily. In case there is a repair required, the problem can be solved fast.