Modularization of Machining Graphite Reactor Internals for HTR-PM

advertisement

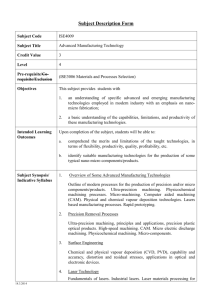

Modularization of Machining Graphite Reactor Internals for HTR-PM Guobin Zhan Dalei Yuan 2014-9-18 SHANGHAI TOYO TANSO Co., Ltd. CONTENT ★Shanghai Toyo Tanso Profile ★Machining requirements and characteristics of machining of graphite reactor internals ★Develop standardized and modularized machining Modularization of materials Modularized machining program Standardization of machining jig Standardized machining internal test Standardized CMM inspection Modularized machining Pre-assembly ★Summary and Subject 2 SHANGHAI TOYO TANSO PROFILE • • • • Shanghai Toyo Tanso(STT) which was found by Toyo Tanso Co., ltd in Japan, is one of the four subsidiaries in China. Shanghai Toyo Tanso was established in August 1994, the registered capital is 17.4 million dollars Address: No. 486, XinFei Road, Songjiang, Shanghai, China Gross area: 66000M2 Buliding area: 20000M2 Employee:240 STT is mainly specialized in the manufacturing, processing and distribution of various special graphite products which are widely used in many industrial fields such as semiconductor, photovoltaic, optical fiber, metallurgy, non-ferrous metal, molds, etc. 3 SAMPLES OF MACHINED COMPONENTS 4 MACHINING REQUIREMENTS AND CHARACTERISTICS OF GRAPHITE REACTOR INTERNALS① Top reflector Side reflector 15m Hot chamber Graphite block 3500 pcs Small parts 26000pcs 5 MACHINING REQUIREMENTS AND CHARACTERISTICS OF GRAPHITE REACTOR INTERNALS ② 4.5m standard of machining precision:GB/T1800.3-1998 High precision geometric dimension and position dimension Large number of components 3500 pcs Graphite blocks and , 26000pcs small parts High precision requirement for pre-assembly Long processing lead time Large investment 6 DEVELOP STANDARDIZED AND MODULARIZED MACHINING A. Requirements Standardized quality and size of material Reasonable machining program High machining precision equipment, with positioning jigs and tooling Management of machining environment and Collecting dust Management of processing time Design of lifting tools for preassembly Standardized pre-assembly Standardized inspection and measurement B. Factor Material :about 4000Pcs Machining equipmentt : Sawing machine 2 Precision machining equipment 13 ( Five axis machining center) CMM 2 Laser tracker 1set Employees 40 Jig 10set Assembly platform :5m*5m 1set Machining program about 160 Target: develop a kind of standardized and modularized machining model through reasonable combination of each factor of B to meet the requirements of A. 7 MODULARIZATION OF MATERIALS IG-110 The material(IG-110) has been finished. All technical 4-2-1 indexes satisfied the design requirements ,especially for 4 Impurity content ,Boron equivalent, Strength and 4-2-1-4 Uniformity. This is a good base for machining and preassemble. Design 12 kinds of standardized material ,according to the drawings, to improve the machining efficiency and material utilization 8 MODULARIZED MACHINING PROGRAM All the machining programs are made in advance 9 MODULARIZED MACHINING PROGRAM 10 MODULARIZED MACHINING PROGRAM STT select the most effective processing technology based on lots of validation for typical characteristic of graphite brick, such as mortise and keyslot ,compare the distinction for different processing parameter and technology . 11 STANDARDIZATION OF MACHINING JIGS Design modular jig according to the drawings help to reduce time of locating jig , ensure the precision, be convenient operation. 12 MODULARIZED MACHINING JIGS 13 STANDARDIZED MACHINING INTERNAL TEST The processing equipment is able to check all the key dimension and key structure automatically at every operating station, that means the geometric dimension of component can be checked during machining process. 14 STANDARDIZED CMM INSPECTION More than 170 CMM inspection programs are prepared in advance 15 MODULARIZED MACHINING HAF003 quality system, standard procedure 3-4-1 3-4-1 Modularized machining of small parts Library automation Machine library Machine tool library Machining program library 3-4 3-4 Modularized machining of graphite block Cutter library Inspection program library 16 MODULARIZED MACHINING Material library Machine library A D B E C A B C Machine tool library D E …... B D E B D E C …... C …... …... CMM program library Machining program library A A A B D E C Cutter library A B D E C …... …... 17 PRE-ASSEMBLY 2:clockwise assembly StepStep 3: counterclockwise assembly Step1 :assemble inner ring Step 4:Assemble final 4 components 18 SUMMARY AND SUBJECT • It is difficult to satisfy the requirement of the quality and delivery time with traditional machining mode. Making process easy to handle, STT is developing an efficient way which can make the task can be done by a style of standardization and modularization. That means we arrange and organize 4M1E (Man, Machine, Material, Method and Environment) based on standardized or modularized processes. STT have confidence that we can deliver qualified graphite reactor internal to client according to the contract .STT will make contribution to HTR-PM. • The machining process has already started from this month, will be completed in July 2017. The overall processing time is over 50,000 hours! The subject to be discussed for the next coming HTR projects is how to improve the machining efficiency further more based on the practice in STT this time, for example, how to shorten processing time from 22 months to 12 months. • Hereby, thanks our client, Chinergy ,Tsinghua University and Huaneng group, they offer great support and help for the machining project, also thanks our talent staffs, T.Imamura, G.Hatou, Jian Liang, Gang Hu, Dalei Yuan, and others, they contribute their wisdom and effort which could be make the machining process in a kind of modular style. 19 Thanks for your attention. 20