2013

advertisement

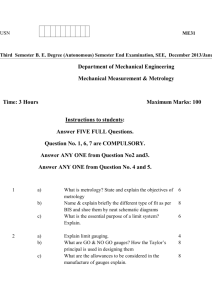

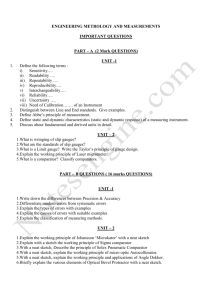

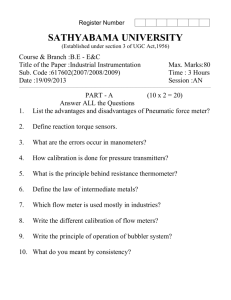

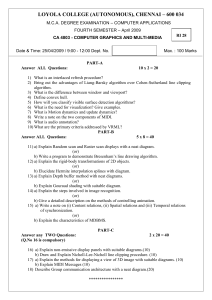

Code No: V3213 R07 Set No: 1 III B.Tech. II Semester Supplementary Examinations, January - 2014 METROLOGY AND SURFACE ENGINEERING (Mechanical Engineering) Time: 3 Hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks ** 1. a) Describe in detail about the types of fits with neat sketch. b) Explain about various types assemblies and advantages of each assembly. [8M] [8M] 2. With neat sketches explain about a) Depth micrometer b) Bevel protractor [8M] [8M] 3. List out various types of interferometers and briefly describe any two of them. [16M] 4. Describe the following surface roughness measurement systems a) Surface inspection of comparison method b) Direct instrument systems [8M] [8M] 5. Describe with neat sketches, any two measuring instruments for the measurement of screw thread. [16M] 6. In certain cases the permitted errors machine tool alignment is unilateral only. Explain why? Enumerate three examples with reasons for unilateral tolerances? [16M] 7. a) Describe the determination of the accuracy of a gear tooth vernier caliper ? what is the expected order of accuracy of this instrument? [8M] b) What are the elements of gears which are checked for accuracy? [8M] 8. Explain the following degreasing techniques a) vapour degreasing b) Ultrasonic degreasing [8M] [8M] ** 1 of 1 |''|'||||''|''||'|'| Code No: V3213 R07 Set No: 2 III B.Tech. II Semester Supplementary Examinations, January - 2014 METROLOGY AND SURFACE ENGINEERING (Mechanical Engineering) Time: 3 Hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks ** 1. a) Explain the various types of standards with their letter symbols for tolerances. [8M] b) Describe in detail about writing tolerances with neat sketches? [8M] 2. a) Discuss in detail about various types of dial indicators with neat sketches? [8M] b) With neat sketches explain about plug and ring gauges for GO gauge & NO GO Gauge systems? [8M] 3. What are the most common aberrations found in optical projectors? Explain how they are used. [16M] 4. Discuss in detail about Tomlinson surface meter with a neat sketch. 5. Explain about various pitch errors in gears? What are the effecting parameters for pitch errors and explain any three of pitch errors in gears? [16M] 6. a) Distinguish between alignment test and performance test of machine tool. [4M] b) Discuss with neat sketches how you would test the Spindle Centre run-out and Chuck-run out? [12M] 7. Explain the following gear accuracy systems. a) Kinematic accuracy. b) Tooth bearing contact. 8. Describe the flame spraying coating process with a neat sketch. ** 1 of 1 |''|'||||''|''||'|'| [16M] [8M] [8M] [16M] Code No: V3213 R07 Set No: 3 III B.Tech. II Semester Supplementary Examinations, January - 2014 METROLOGY AND SURFACE ENGINEERING (Mechanical Engineering) Time: 3 Hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks ** 1. 2. a) Explain about Hole and Shaft basis system with neat sketches. [8M] b) Discuss in detail about difference between tolerance and allowance of limit systems [8M] a) Explain about calibration process with slip gauges using different grades and sets available in slip gauges. [8M] b) With a neat sketch explain the determination of the included angles using sine bar and give the applications of sine bar. [8M] 3. Explain about Tool maker’s microscope with a neat sketch and give its applications. [16M] 4. Explain the following analysis of surface traces a) Maximum peak to valley height of roughness b) Center line average method [8M] [8M] Discuss in detail the following effective diameter measurement methods: a) Thread micro meter method b) One-wire method [8M] [8M] 5. 6. Describe two methods of testing a center lathe for accuracy of facing? Why must the surface generated not be convex? [16M] 7. a) Describe gear tooth vernier caliper and explain how is it used to check gears. b) Calculate the settings for a straight spur gear having 50 teeth of module 3mm. [8M] [8M] 8. a) What is surface coating? Why is it provided on various products? b) Briefly explain about Plasma Spraying. [8M] [8M] ** 1 of 1 |''|'||||''|''||'|'| Code No: V3213 R07 Set No: 4 III B.Tech. II Semester Supplementary Examinations, January - 2014 METROLOGY AND SURFACE ENGINEERING (Mechanical Engineering) Time: 3 Hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks ** 1. a) Explain the effect of engineering allowance on the different types of fits required in engineering manufacture. [8M] b) Discuss the effect of temperature on tolerance limits and what precautions are required during measurements. [8M] 2. a) Classify and explain plain limit gauges. b) Sketch and explain about four types of plug gauges. [8M] [8M] 3. Explain about optical flats and describe the monochromatic light wave interference method in metrology? [16M] 4. Why the assessment of surface texture is is important? Describe the two methods to obtain a numerical value of the texture from a given graphical method. [16M] 5. a) How would you check the accuracy of pitch of a plug screw gauge? Explain. [8M] b) How the thread form can be checked and flank angle of internal thread measured? Explain. [8M] 6. a) Distinguish between the geometric and practical tests on machine tool. [8M] b) What is the effect upon the work if the centre tee-slot of a horizontal milling machine is not square with the spindle axis? [8M] 7. Describe the spur gears with reference to a) Lead b) Module [8M] [8M] 8. a) It is necessary to clean the surface before providing coating on it. Explain why? [8M] b) Classify and briefly describe various mechanical cleaning processes? [8M] ** 1 of 1 |''|'||||''|''||'|'|