Industrialization

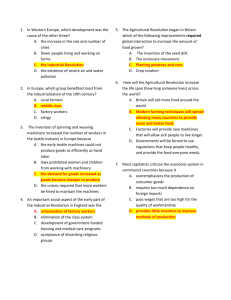

advertisement

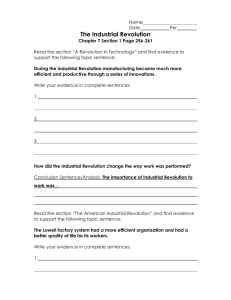

Industry APHG Spring 2015 Industrialization • What is it? • Where? • Why? • Why care? What 2 things were needed in order to manufacture products at the beginning of the Industrial Revolution? 1. Close access to raw materials 2. Ability to move materials (waterway) Why big cities like London and Paris? Is this true today? Would you add any other factors? Economic Classification • Production / Consumption / Distribution • Sectors – Primary – Secondary – Tertiary – Quaternary Industrialization is the process by which economic activities evolved from producing primary goods to factories that mass-produce goods. 5 Western European Nations and the US followed Britain Britain Industrializes Wealth became a sign of virtue instead of kinship. 6 The Industrial Revolution • Pre-Industrialization: what did the Revolution change? – People had made goods for thousands of years before IR • things made slowly (low productivity), all by hand • workmen handled all facets of production > different quality goods • guilds created production standards, but prices were high Before the Industrial Revolution There were industrial centers before the late 18th Century but it was isolated. Most industries were cottage industries. Examples: Chinese Silk Factories Metal Workshops in India 8 The Early 18th Century Early factories in Great Britain during the 18th Century were run by water running down slopes. 9 The Most Important Invention In 1769, James Watt built the first efficient steam engine. This was the most important invention to the Industrial Revolution. 10 Assembly Line Production • 1920’s – Henry Ford – Assembly Line Production – Interchangeable parts – Mass Production • Division of Labor New Industrial Concepts • International Division of Labor • Just in Time Production Time-Space Compression • Just-in-time delivery rather than keeping a large inventory of components or product, companies keep just what they need for short-term production and new parts are shipped quickly when needed. Two issues can result from reliance on just-intime delivery: labor unrest and “Acts of God” • Global division of labor corporations can draw from labor around the globe for different components of production This labor can be skilled or unskilled. Current Industrial Patterns • Develop faster / Richer? • Levels of Development – Material condition of people – Everywhere / some level of development Great Britain Diffusion of the Industrial Revolution Belgium/France (late 1700s) The United States (1790s) Most of Europe came late to the party because of revolution and strife (ie. French Revolution, Napoleonic Wars) Italy, Netherlands, Russia, Sweden (late 1800s) The United States entered the IR later than Belgium and France but expanded more rapidly. The Middle East and Africa entered the IR because of WWI and the need for oil. Asia, Middle East and Africa (Mid 20th Century) 16 Why do you think that some places were affected by industrialization while others were not? 18 Diffusion to Mainland Europe • In early 1800s, innovations diffused into mainland Europe. • Location criteria: • proximity to coal fields; • Connection via water to a port • Flow of capital Later Diffusion •In late 1800s, innovations diffused to some regions without coal. •Location criteria: •Access to railroad •Flow of capital Industrial Regions The world’s major manufacturing regions are found in North America, Europe, and East Asia. Other manufacturing centers are also found elsewhere. Industrial Areas in Europe Industrial Areas in North America Manufacturing Centers in East Asia Many industries in China are clustered in three centers near the east coast. In Japan, production is clustered along the southeast coast. What is the hearth? What is diffusing? What historic patterns can you identify? EXIT SLIP: 1. Why was Great Britain the first country to become industrialized? 2. What changes occurred with the steam engine, new machinery, and the factory system? MUDDY WATERS… What idea/concept did you not understand from today’s lesson? Can you predict where a factory should locate? • What is the goal of any factory? Profit = Price - Costs • Assuming: – Labor cost the same and is available anywhere – There is only one market – Topography is flat – Transportation costs are a direct result of weight • Where would you put a factory? Primary Industry • Develops around natural resources. Secondary Industry • Develops as transportation improves. • Less dependent on location 27 Variable Costs Secondary Industry Locations Distance Decay Friction of Distance 28 Situation Factors •Transportation Issues •Bulk-Gaining, Bulk Losing Site Factors •The cost of Land, Labor, and Capital •Climate •Access to Amenities 29 Situation factors • Inputs – Heavy, bulky, fragile – locate near the inputs • Known as Bulk-reducing • EX. Copper, steel, canned tomatoes • Outputs – Heavy, bulky, fragile – locate near market • Bulk-gaining • Beer, glass, concrete Transportation Factors • Methods – Ship (ocean, lake, river) • Very Low cost, very slow, long-distance, nonperishables – Rail • Low cost, slow speed, long/med. Distance – Trucking • High cost, mod to high speed, any dist., very flexible – Air • Very high cost, very high speed, med/long dist. – Pipeline • Very low cost, LIQUIDS! Types of Transportation Mode of Transportation Advantages Disadvantages Trucks •Can go anywhere there are roads •Fair amounts, large distance, relatively quickly •Weather Delays •Traffic •Fossil Fuels •Maintenance Trains •Efficient and Cost-effective •Immense amounts long distances •Inflexible routes •Break-of-bulk points needed •Can’t cross oceans Airplanes •Fastest means •High flexibility •Most expensive •Break-of-bulk points needed •Weather delays Pipelines •Highly efficient ways to move liquid and gas •Very safe delivery method •Limited to gas and liquid •Expensive to build •Costly to move a pipeline Ships •Most energy efficient •Slowest method •Need access to waterway •Break-of-bulk points needed •Weather delays and Port costs Site factors • Physical characteristics of a place. • Different industries have different needs. • Availability and cost of: – Land (lg areas – Airplane manufacturing) – Power (lots of electricity or fuel – Aluminum) – Labor (unskilled – electronics, skilled – research/dev) – Capital (Money, money, money…money!) • Footloose Industries – – Can locate anywhere (Diamonds, computer chips - YUMM) Location Models Weber’s Model Manufacturing plants will locate where costs are the least (least cost theory) Theory: Least Cost Theory Costs: Transportation, Labor, Agglomeration Hotelling’s Model Location of an industry cannot be understood without reference to other industries of the same kind. Theory: Locational interdependence Losch’s Model Manufacturing plants choose locations where they can maximize profit. Theory: Zone of Profitability http://ed.ted.com/lessons/why-do-competitors-open-their-stores-next-to-one-anotherjac-de-haan#watch Weight Reducing Industry Resource 1 Weight Gaining Industry What is this model called? Weber’s Least Cost Theory (Industrial Location Theory) MARKET Footloose Industry Resource 2 Weber’s Least Cost Theory • Factory Location – Least Cost to the Factory / Company • Assumptions – Cost of Transportation • Weight • Distance – Maximize Profits • Minimize Cost Weber’s Least Cost Theory • Assumptions – Markets are fixed – Labor is fixed – Uniform Landscape – 4 Main Drivers • • • • Transportation Labor Agglomeration Deglomeration Weber Key Ideas • Friction of Distance: The greater the weight the greater the cost The greater the distance the greater the cost The greater the time the greater the cost (think veggies!) • Focused on Costs : Variable Costs! Profit = Price – Costs Hotelling’s Model Locational Interdependence • Variable Revenue: – Maximize Profits not minimize costs! Profit = Price – Costs Find the location that provides the best profit …and where other industries are located. Can you create a Spatial Monopoly? Losch Model (pronounced laesch) • You can look at one point…but maybe a bunch of points will work. • And things can change…replace labor with machines? Increase transport costs but reduce land rent? Time to apply some theories… Using Weber, Hotelling, and Losch… Where would you sell doughnuts in the morning for OHS? Use the school map provided. What is a Post Industrial World? What does it look like? • Tertiary, quaternary, and quintary sectors. • Deindustrialization? • Increasing Mechanization • Multinational Corporations • Post-Fordist Production • Global Division of Labor • Global Production Chain • Can outsource services – Who prepares the food and cleans the place? Where is it located? Core countries still Sunbelt in US With Services…what is more important? Resources Markets Why call centers in India? What is a high tech corridor? (IL Research and Technology Corridor…Silicon Prairie?) Why Are Location Factors Changing? • Attraction of new industrial regions – Changing industrial distribution within MDCs • Interregional shift within the United States – Right-to-work laws – Textile production • Interregional shifts in Europe – Convergence shifts – Competitive and employment regions – Changing distributions – Modern Production • Outsourcing - moving individual steps in the production process (of a good or a service) to a supplier, who focuses their production and offers a cost savings. • http://www.metatube.com/en/videos/10420/TheSimpsons-India-Outsourcing/ • Offshore – Outsourced work that is located outside of the country. Deindustrialization • a process by which companies move industrial jobs to other regions with cheaper labor, leaving the newly deindustrialized region to switch to a service economy and work through a period of high unemployment Abandoned street in Liverpool, England, where the population has decreased by onethird since deindustrialization. Key Question What is the Service Economy, and Where are Services Concentrated? Service Economy • Service Industry • Economic activity associated with the provision of services – such as transportation, banking, retailing, education, and routine office-based jobs. Geographical Dimensions of the Service Economy • New influences on Location: - information technologies - less tied to energy sources - market accessibility is more relevant for some and less relevant for others because of telecommunications. - presence of Multinational Corporations Wal-Mart Requires producers of goods to locate office in the Bentonville, Arkansas (Wal-Mart’s headquarters) area in order to negotiate deals with Wal-Mart. Proctor & Gamble put their office in nearby Fayetteville, Arkansas. How does the presence of these companies in the region change the region’s economy and its cultural landscape? Nike Headquartered in Beaverton, Oregon,. Nike has never produced a shoe in Oregon. Beginning in the 1960s, Nike contracted with an Asian firm to produce its shoes. Skopje, Macedonia The swoosh is ubiquitous, but where is the shoe produced? Nike has a global network of international manufacturing and sales High – Technology Corridors • An area designated by local or state government to benefit from lower taxes and high-technology infrastructure with the goal of providing hightechnology jobs to the local population. eg. Silicon Valley, California • Technopole – an area planned for high technology where agglomeration built on a synergy among technological companies occurs. eg. Route 128 corridor in Boston