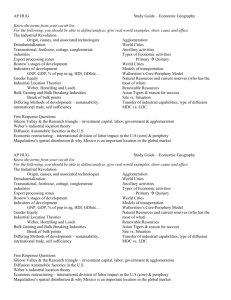

Industry & Cost

advertisement

Industry & Cost Learning Targets: • I can identify site and situation factors that influence decisions about locating industries, including the Weber’s Cost Theory. • I can identify the primary factors influencing the regional pattern of economic activities in the United States and the World. Distribution of Industry ● Three-fourths of the world’s manufacturing is clustered in three regions: ● Europe ● North America ● China Factors in locating industry ● Site- where and why a city develops and changes ● Situation factors involve transporting materials to and from a factory. •Water •Railroads Situation Factors A firm seeks a location that minimizes the cost of transporting inputs to the factory and finished goods to the consumer. - The farther something is transported the higher the cost. - A Manufacturer tries to locates its factory as close as possible to both the buyers and sellers Site Factors in Industry ● Site factors result from the unique characteristics of a location ● The three main site factors are labor, land, and capital ○ ○ ○ Labor intensive industry-wages and labor are a high percentage of costs Land industry-need room for production and access to goods Capital-Manufacturers borrow capital or money to establish new factories Weber’s Cost Theory Alfred Weber (1868-1958) formulated a theory of industrial location in which an industry is located. - Where it can minimize its costs, and therefore maximize its profits. Weber’s Cost Theory- Continued Weber’s least cost theory accounted for the location of a manufacturing plant in terms of the owner’s desire to minimize THREE categories of cost: 1. Transportation (most important) 2. Labor 3. Agglomeration 1.Transportation *Most important in Weber’s theory! The site chosen must entail the lowest possible cost of moving raw materials to the factory, and finished products to the market. - Weight and distance are the two most important factors that influence shipping costs. - The mode of transportation is primarily dictated by the distance and product value. Inputs and products are transported in one of four ways: 1. Boat (cargo ships) 2. Railways 3. Truck (semi-trucks) 4. Air (airplanes) ● Every time a good is transported to another transportation mode the cost goes up - A Break-of-bulk point is a location where transfer among transportation modes is possible (ex: truck to air) 2.Labor Higher labor costs reduce profits, so a factory might do better farther from raw materials and marketplace if cheap labor is available. Even if it might have a higher transportation cost, if the labor is cheap enough, it is worth it! 3.Agglomeration When a large number of enterprises cluster (agglomerate) in the same area (e.g. city) - As a result, they can provide assistance to each other through shared talents, services, and facilities Putting the Model Together... Agglomeration This will move based on the price of transportation, labor, and need for being near other businesses! Location of Plant Labor Transportation Proximity to Markets ● Bulk-gaining industries ○ Something that gains volume or weight during production • Ex: Beverages (soda) ● Single-market manufactures ○ Makes products sold primarily in one location • Ex: General Motors or Toyota ● Perishable Products ○ Must be located near their markets because they can spoil. • Ex: Meat and produce Central Place Theory Central Place Theory looks at the location of consumer services in terms of: - Market area: Selecting the right location - Range: Maximum distance people are willing to travel to use a service - Threshold: Minimum number of people needed to support the service