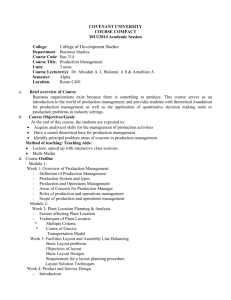

Process View of Organization

advertisement

Process and Layout Choices References: Ballou, Business Logistics Management, 4th Ed., Prentice-Hall, 1999. Anupindi, Chopra, Deshmukh, Van Mieghem, Zemel, Managing Business Process Flows, Prentice-Hall,1999. 1 Process View of Organization Input Value added Goods Services 2 Process Architecture/Structure 1. Inputs and outputs 2. Flow units 3. Network of activities and buffers 4. Resources (capital and labour) 5. Information structure 3 Table 1.1 (ACDVZ, p. 5) Table 1.1 Some Generic Business Processes Process Flow Unit Input-output Transformation Order fulfillment Orders From the receipt of an order to the delivery of the product Production Products From the receipt of materials to the completion of the finished product Outbound logistics Products From the end of production to the delivery of the product to the customer Supply cycle Supplies From issuing of a purchase order to the receipt of the supplies Customer service Customers New product development Projects From the arrival of a customer to the departure From the recognition of a need to the launching of a product Cash cycle Cash From the expenditure of funds (costs) to the collection of revenues 4 A Business Process is a network of activities performed by resources that transforms inputs into outputs. Process Flow Management is a set of managerial policies specifying how a process should be operated over time. Design of processes How and when to operate Resources allocated Goal: Improve performance 5 Product Attributes Cost Total costs (purchase and maintenance) incurred by customer to own and experience the product Delivery response time Total time a customer waits before receiving the product Depends on availability and accessibility Product variety Range of choice to meet needs of customer Quality What functions and how well product performs Depends on product design and conformance to standards 6 Product Space A product is a bundle of these four attributes. A point in the 4-dimensional product space. Customers make trade-off between different product choices, according to her utility. Company must select the right combination of attributes for product range to appeal to target market segment. 7 Goods vs. Services ? Services are experiential, requiring close interaction between service providers, and participation by the customer Services cannot be produced in advance and stored as inventory Service quality difficult to measure 8 Process Attributes Process Cost Total costs incurred in producing and delivering outputs Process Flow Time Total time needed for transforming one unit of input into output Process Flexibility Ability of the process to produce and deliver desired product variety Process Quality Includes process accuracy, conformance to design specifications, reliability and maintainability 9 Flow-Time Analysis Flow time is the total amount of time a flow unit spends in a process, and includes: Theoretical flow time – minimal time required for processing if no waiting occurs, Waiting time – time spent waiting to be processed. Flow-time efficiency = . theoretical flow time . average total flow time 10 Flow-time as performance measure Flow time affects response time Short flow time leads to lower inventory Little’s law WIP earns no revenue, incurs costs Short flow time in product design and development => early market introduction => first-mover advantage Short manufacturing flow time => can delay production until better demand forecast Short flow time requires better quality control 11 Process Flow Chart A graphical representation of all the elements that make up a process Decisions Activities Buffers Transport Delay Events Information flow Resources Value-added and non-value added activities Sub-processes and cascading 12 Theoretical Flow Time Activity time is the time required by a typical flow unit to complete the activity once Repetitions of the activity during processing are called visits Can be fractional to represented expected proportion that needs rework Work content is the activity time multiplied by average number of visits. 13 Critical Paths and Critical Activities If unit is processed sequentially (process chart consists of a single path), total theoretical time is sum of work content. If process consists of parallel and sequential activities, a flow unit can exit only after all the activities along all the paths are complete. Theoretical flow time is the time to complete the longest path(s) in the process flow chart. Any such path is a Critical path; activities on path are critical activities Delay of critical activities delays total flow-time 14 The Critical Path Method CPM (critical path method) J. E. Kelly of Remington-Rand and M. R. Walker of Du Pont (1957) Scheduling maintenance shutdowns of chemical processing plants PERT (program evaluation and review technique) U.S. Navy Special Projects Office (1958) Polaris missile project 15 CPM Framework Set of activities with precedence relationships 1. Develop activity network with precedence relationships and activity times. 2. Compute the critical path (the longest path through the network). 3. Use the network to plan, schedule, monitor and control the project. 16 CPM Example CPM ACTIVITY DESIGNATIONS AND TIME ESTIMATES Activity Designation Immediate predecessors Time in weeks Design A - 21 Build prototype B A 5 Evaluate equipment C A 7 Test prototype D B 2 Write equipment report E C, D 5 Write methods report F C, D 8 Write final report G E, F 2 7 8 C F G A 21 2 B D E 5 2 5 17 Earliest start time (ES) : the earliest time that an activity can begin (without violating precedence relationships) Earliest finish time (EF): the earliest time an activity can finish 7 8 C F G A 21 2 B D E 5 2 5 18 Latest finish time (LF) : the latest time that an activity can finish (without delaying the entire project) Latest start time (LS): the latest time an activity can start (without delaying the entire project) 7 8 C F G A 21 2 B D E 5 2 5 19 A Critical Path A critical path is a sequence of activities that establishes the earliest completion time. A delay (or increase in duration) of any activity on the critical path delays the entire project. Slack = amount of time an activity can be delayed without delaying the entire project Slack = LS - ES = LF - EF 20 Managing Theoretical Flow Time Decrease work content of activities on critical path(s) “Principles of Scientific Management” – Taylor, Gilbreths Move some work content off the critical path 21 Reducing Work Content Work smarter Work analysis – eliminate unnecessary and non-value added activities Work faster Change process and/or environment to reduce fatigue Offer incentives to boost morale Acquire faster equipment Do it right the first time Improve quality, reduce rework Statistical process control, Autonomation Change the product mix Focus on products in demand and has short processing times 22 Moving Work OFF the Critical Path Move to non-critical path Concurrent engineering Parallelize activities Move work to “Outer Loop” Pre-processing Post-processing 23 Process Choice Process types: project job batch line continuous Best choice depends on volume and degree of customisation of goods and services produced. 24 Project process one-of-a-kind products complex, large scale and scope high degree of job customisation unique process/task sequence release of substantial resources on completion e.g. technology/product development, political campaign, construction, Y2K assurance Firm’s competitive focus on capabilities rather than products 25 Job Process high customisation, low volume each job has different processing sequence order-bidding, repeat orders infrequent and unpredictable flexible workforce and equipment make-to-order e.g. emergency room care, customised furniture/machine parts manufacture, “health farms” Firm’s resources organised around the process. 26 Batch Process higher volume narrower range of services and products assemble-to-order production in batches, “rotating” through the product range jumbled flow patterns, but with some dominant paths e.g. packaged tours, parts manufacturing for an assembly line, grants/admissions processing 27 Line Process (Mass production) high volume standardised products or services materials move “linearly” from operation to operations in fixed sequence production orders not linked to customer orders make-to-stock (finished goods inventory) e.g. automobile/appliance manufacture, fastfood restaurants Mass customisation? 28 Continuous Process high volume rigid line flows single product capital intensive specialised equipment “non-stop” production e.g. petroleum refinery, beer production, electricity generation 29 Layout Planning The physical arrangement of economic activity centres within a facility. Which centres to consider? How much space? Configuration? Location? Relative position Absolute location 30 Production/Service Layout: General Principles Product Layout vs Process Layout 31 Product layout Equipment placed along the “flow-path” of a particular product e.g. assembly lines Equipment duplicated to avoid “backtracking” Dedicated equipment, low flexibility Low unit processing costs, low WIP inventory Appropriate for high volume production, low product variety Key: avoid bottlenecks, balance workload, avoid unnecessary idleness 32 1. Review application for correctness 2. Process and record payment 3. Check for violations and restrictions 4. Conduct eye test 5. Photograph applicant 6. Issue temporary license (state trooper) 33 • Capacity analysis • Flow analysis 34 Assembly Lines Product manufactured by visiting a sequence of workstations PACED - each workpiece spend exactly the same amount of time at each workstation (Cycle time = C) Cycle time determined by desired production rate Assembly line balancing tasks, precedence relations determine no. of workstations and task assignments (n) Efficiency = (Total task time)/[(Cycle time)(#workstations)] 35 Assembly line balancing example Precedence graph for model J. Wagon 12s 11s 40s B 9s F C A 12s G 50s 15s 12s D E H J K 8s 9s I 12s 36 Assembly line balancing example C = cycle time = 50.4 seconds A. Balance made according to largest number of following task rule Task Task time (s) Remaining unassigned time (s) Feasible remaining tasks Task with most followers Task with longest operation time Station 1 A 45 5.4 Idle None Station 2 D 50 0.4 Idle None Station 3 B E C F* 11 15 9 12 39.4 24.4 15.4 3.4 C,E C F,G,H,I E Idle C,E C,H,I F,G,H,I None G H* I J 12 12 12 8 38.4 26.4 14.4 6.4 H,I H,I Idle H, I I J None K 9 41.4 Idle None Station 4 Station 5 F,G,H,I *Denotes task arbitrarily selected where there is a tie between longest operation times Efficiency = T / NC = 195 / (5)(50.4) = 77% 37 Assembly line balancing example WS1 45s 11s B WS3 12s 9s F C A 12s G 50s 15s 12s D E H WS5 WS2 I J K 8s 9s WS4 12s 38 Process Layout Similar equipment or functions grouped together Appropriate for low-volume, high-variety production Each product visit the functional areas (departments) in a different sequential order e.g. hospitals, mail-order warehouse, job shops In service context: allow each customer to define his/her own sequence of service activities (customization) general purpose equipment, flexible to adapt to new products loss production due to setups, fluctuating workloads jumbled work flow, costly material-handling waiting between activities , higher WIP inventory Key: job dispatching, minimize material handling costs 39 Ocean World Theme Park Major attractions: A: killer whale B: sea lions C: dolphins D: water skiiing E: aquarium F: water rides Want to minimize visitors’travel distance between attractions. (From Fitzsimmons and Fitzsimmons,Service Management for Competitive Advantage) 40 41 CRAFT (1964) (Computerised Relative Allocation of Facilities Technique) Tries to place departments with large interdepartmental traffic adjacent to each other Data requirements: interdepartmental flow cost per unit distance travelled SPACECRAFT multi-storey layout 42 CRAFT Cost of layout = pairwise sum of (flow)(distance)(cost/unit distance) Heuristic: starts with an initial layout interchange of locations of two departments if cost reduced stop when no pairwise improvements found Limitations: optimality not guaranteed distance may not be reflect true material handling costs Assumes every department same-sized and rectangular 43 44 Process Layout: Systematic Layout Planning Numerical flow of items between departments Can be impractical to obtain Does not account for the qualitative factors that may be crucial to the placement decision Systematic Layout Planning Accounts for the importance of having each department located next to every other department Is also guided by trial and error Switching departments then checking the results of the “closeness” score Copyright: The McGraw-Hill Companies, Inc., 1998 45 Systematic Layout Planning-Example: Reasons for Closeness Code Reason 1 Type of customer 2 Ease of supervision 3 Common personnel 4 Contact necessary 5 Share same price 6 Psychology Copyright: The McGraw-Hill Companies, Inc., 1998 46 Systematic Layout Planning-Example Importance of Closeness Line code Numerical weights Value Closeness A Absolutely necessary 16 E Especially important 8 I Important 4 O Ordinary closeness OK 2 U Unimportant 0 X Undesirable 80 Copyright: The McGraw-Hill Companies, Inc., 1998 47 Systematic Layout Planning--Example Relating Reasons and Importance From 1. Credit department 2. Toy department 2 I 3 U 6 -U -- To 3. Wine department 4 A 5 U 4 I 1 U -- -A 1,6 X 1 X 1 4. Camera department 5. Candy department Irwin/McGraw-Hill Area (sq. ft.) 100 400 300 100 100 Letter Closeness rating Number Reason for rating 48 Systematic Layout Planning-Example Initial Relationship Diagram E 1 I 3 4 U 2 U 5 A Copyright: The McGraw-Hill Companies, Inc., 1998 49 Systematic Layout Planning-Example Initial and Final Layouts 5 2 3 2 4 1 3 5 1 20 ft 4 50 ft Initial Layout Final Layout Ignoring space and building constraints Adjusted by square footage and building size Copyright: The McGraw-Hill Companies, Inc., 1998 50 Flow shops – Product Layout Uses specialized resources that perform limited tasks but with precision and speed Limited product variety, large volume High fixed cost spread over huge volume, leading to low per unit cost Resources located according to the sequence of activities needed to produce particular product; may duplicate resources Low unit processing cost, high volume, consistent quality 51 Job Shop – Process Layout Uses flexible resources to produce low volumes of customized high-variety products Uses general purpose equipment Resources with similar functional capabilities located in close proximity Many products simultaneously flowing through, each with its own route Jumbled work flows, large WIP, waiting between activities Frequent setups, fluctuating workload, long flow times High process flexibility and product customization 52 Matching Products and Process Hayes and Wheelwright (1979) 53 External Performance Measures Estimate a firm’s ability to attract and retain customers Competitive industry analysis Demand estimates Customer satisfaction survey Cost of attracting new customer is 5 times that of keeping old customers Only 4 % of dissatisfied customers bother to complain Lagging indicator 54 Internal Performance Measures External measures can be linked to internal measures via the process attributes Process Cost Per unit production cost Process Flow Time Lead time and delivery time Process Flexibility Customization, delivery response time Process Quality Failure rates 55 Process Planning Strategic Positioning and Operational Effectiveness Strategic Fit Terry Hill’s procedure to develop a manufacturing strategy 56 Operations Frontier The smallest curve(surface) that contains all the current industry positions Firms located on the same ray (from origin) share same competitive priorities Firms on operations frontier have superior performance (best practices, benchmarks) Operational effectiveness measured by “distance” between current position and the operations frontier Concave frontier => tradeoffs between performance dimensions Operational frontier shifts outward 57 The Operations Frontier 58 Process Flow Measures Questions: Average flow rate? Units processed per unit time? Average flow time? Time unit spends within “process boundaries” Average Work-in-Process? Units being process 59 Flow rate and flow time Flow rate = number of units flowing through a specific point in process per unit time Stable process : average in flow rate = average out flow rate (throughput rate) Flow time = processing and waiting time May vary from unit to unit depending on process choice 60 WIP Inventory Inventory accumulation rate = inflow rate – outflow rate Little’s law: I=RxT Inventory turns (turnover ratio)= Ratio of throughput to average inventory = R/I = 1/T 61 Managing Flow Rate Flow rate depends on: theoretical capacity resource unavailability & idleness Manage supply and demand have reliable suppliers better forecasts Decrease resource idleness synchronise flows to reduce starvation set appropriate buffer size to reduce blockage Increase net availability improve maintenance improve worker morale, reduce absenteeism reduce setup/changeover frequency Increase theoretical capacity decrease unit load increase load batch or resource units increase scheduled availability 62 Summary Process choice and impact on competitive priorities Flow Time Analysis Critical Path Method Job shop vs. flow shop Layout Design methods Flow rate/flow time/WIP measures 63