File

advertisement

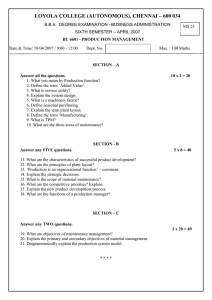

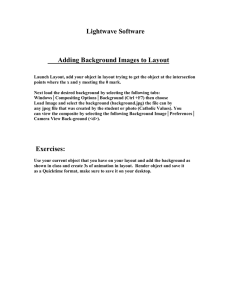

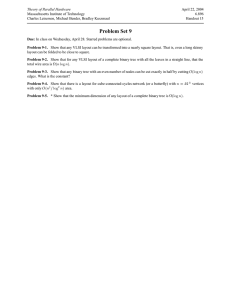

Operation & Production Management INPUT Design Operation Output Nature & Scope Four Functional areas in a business organization. Marketing, Production, Finance And Personnel. All activities revolve around Production. The end product is for the satisfaction of human wants. Basic inputs are Men, Machine, Plant, Services, and Methods. The Raw Materials are from Mine, Sea, Farm and Forest. Definitions Production – Step by step conversion of one form of material to other through chemical or mechanical process. Production Management – Planning, organizing, directing and controlling the activities of the production function. Operation Management – Service oriented industry is broadly known as operations management. Scope in Detail Aim - Customer satisfaction at optimum cost. 1. 2. 3. 4. 5. Product Selection Design Process Selection and Planning Facilities Location Facilities Layout and Materials Handling Capacity Planning Scope in Detail Operational decisions 1. 2. Production Planning Production Control (PPC) 3. 4. 5. 6. 7. Planning Routing Dispatching Follow Up Inventory Control Quality Control Method Study Maintenance & Replacement Cost Reduction And Control Historical Development Adam Smith is the first person who introduced Production Management in 1776. – Emphasized the division of labour – This effected in turn for improving the quality & quantity of goods. Historical Development Charles Babbage in 1883 introduced the principle of limiting skills as a basis for pay fixation. Also agreeing on Adam Smith’s theory. Historical Development Management techniques by F M Taylor. – The workers should not be allowed to evolve their own operations. – Proper selection, training and development programmers given to workers to get the best result. – Close cooperation and understanding between workers and management. – Importance of specialization & expertise to carry different operations. Historical Development Short Comings on Taylor technique – Production Management was very slow. – Study materials were unavailable. – Output depended on man, job and job conditions. Historical Development In 1914 F W Harris introduced the economic lot size method to control the inventory of an Enterprise. In 1931 Walter Schewart introduced statistical quality control. Applied in second World War. In 1934 L H C Tippet developed ‘Sampling Theory’. Applied in Production Analysis in 1950. Where Do We Stand Today? Advent of computer introduced the field of Automation. Efficient use of Labour, Material & Equipment Economies in Production. Continuous improvement in design & layout. Sophisticated production control techniques to produce goods & service at desired time & minimal cost. References Production and Operations Management – R. Paneerselvam – Prentice Hall India Production and Operations Management – Chunawala & Patel – Himalaya Publishing house Production and Operations Management – Kanishka Bedi - Oxford Production Operations Management – Dr. B. S. Goel - Pragati What Next? Operations Strategy Layout Layout Planning