Installation Requirements

advertisement

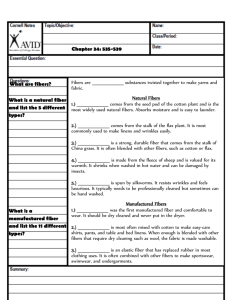

COE Installation Quality Bulletin Installation Quality Bulletin Number: 08-05 To: QTI / Design Engineering Representatives / Quality Managers / Field Engineering Representatives / AMC Representatives / All Contracted Installation Service Suppliers / Work Management Center Representatives Date: Monday, June 9, 2008 From: QWEST Installation Quality Assurance Subject: Termination Procedure for the “72 TERM FMT” fiber optic equipment cable in the Fiber Management Tray (FMT) Panel Action Required: NO: YES: Description of Bulletin: The purpose of this Quality Bulletin is to notify the field of a change in procedure for termination of a 72-fiber equipment cable to a Fiber Management Tray (FMT) panel and how to dress and replace defective fibers within the 72-fiber equipment cable. Note: This will be the new standard for jobs installed after the date of this Bulletin. Installation Requirements 1. The 72-fiber equipment cables shall be terminated to the FMT ports consecutively starting from the bottom-most port (Port #6 – not visible in this view) and continuing upward to the topmost port (Port #1) of Slot 1 and continuing in this fashion for Slots 2 thru 12. Refer to Figures 1 and 2. Figure 1 2. FMT ports shall not be skipped when terminating the 72-fiber equipment cable. 3. All 72 fibers shall be cleaned and scoped and OTR/IL-tested at both ends prior to termination. 4. If testing identifies any defective fiber(s), the Service Supplier shall contact the Qwest Design Engineer to schedule procurement of replacement fibers. 5. In the event a defective fiber is identified in the 72 fiber equipment cable, then the defective fiber shall be cut and removed from the multi-fiber cable. A blunt edge cut shall be made to the defective fiber at the 900 micron fiber level, 2 inches away from the 2 milli-meter up-jacketing of the 12 fiber subunit. To finish the cable, bundle the 2 inch, 900 micron stub with the remaining 900 micron fibers of the subunit and bind with electrical tape. Extreme care must be taken when handling any 900 micron fibers. Refer to Figures 3a and 3b. Figure 2 Figure 3a Figure 3b 6. Single fibers shall be run in the cable rack in place of the defective fiber and terminate to the FMT port vacated by the defective fiber. 7. If multiple adjacent fibers are identified as defective then a multi-fiber cable may be run in place of the single fibers. 8. If more than 12 fibers are identified as defective then the field shall contact the Qwest DE for replacement of the 72 fiber equipment cable. 9. If defective fibers are identified at the time in which the 72 fiber equipment cable is installed and terminated, then the remaining working fibers may be terminated consecutively such that the empty ports are at the end of the 72 count. This will allow a multi-fiber replacement cable to be terminated consecutively to the ports at the rear of the panel. 10. When routing the 900µ fibers through the rubber securing band, ensure that the yellow insulation jacket is the only section of that cable to come in contact with the securing band. The 900µ fibers are not designed to bear any additional tension. Refer to Figure 4, Figure 4 Acknowledgements to Erica Stockford of the AMC group for her contribution to the content of this Bulletin. Questions may be directed to Erica at (303) 707-2745. Qwest Installation Quality Assurance Jeff Bostow 612-798-2460 mailto: jbostow@qwest.com