FACSIMILE TRANSMISSION COVER LETTER

advertisement

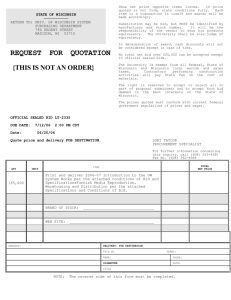

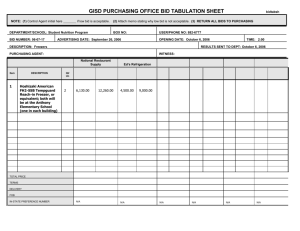

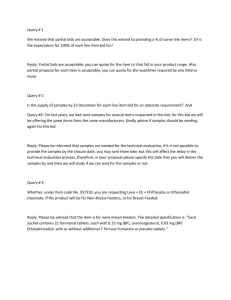

BIDS MUST BE SEALED & ADDRESSED TO: INSTRUCTIONS This request for bid form must be completed, typed or in ink, signed and returned. Bid envelope must be sealed and plainly marked in lower corner with due date and Request for Bid No. Late bids will be rejected. Bids MUST be date and time stamped by the soliciting purchasing office on or before the date and time that the bid is due. UNIVERSITY OF WISCONSIN-PLATTEVILLE PURCHASING OFFICE, 2201 ULLSVIK HALL 1 UNIVERSITY PLAZA PLATTEVILLE WI 53818-3099 THIS IS NOT AN ORDER REQUEST FOR BID NO. CR-2668 Bids dated and time stamped in another office will be rejected. Receipt of a bid by the mail system does not constitute receipt of a bid by the purchasing office. Any bid which is inadvertently opened as a result of not being properly and clearly marked is subject to rejection. Bids must be submitted separately, i.e., not included with sample packages or other bids. Bid openings are public unless otherwise specified. Records will be available for public inspection after issuance of the notice of intent to award or the award of the contract. Bidder should contact person named below for an appointment to view the bid record. Bids shall be firm for acceptance for sixty (60) days from date of bid opening, unless otherwise noted. The attached terms and conditions apply to any subsequent award. Bidder Name & Address: DUE DATE and TIME: Purchasing Agent: SEPTEMBER 25, 2008 – 2:30 p.m. Carol Rauch (608) 342-1221 Quote Price and Delivery FOB: Platteville, Wisconsin Description AMENDMENT REVISION: Specifications have been changed; please review carefully as some items may have been deleted, while new items have been added. Additions are noted in RED. Please submit your bid response on the amended forms, and acknowledge that you have received the amended document. Provide to the University of Wisconsin-Platteville MILLING MACHINES AND LATHE, per the attached Itemized Bid Form, Specifications and Conditions of Bid. BIDDERS TO COMPLETE AND RETURN THE FOLLOWING: 1. Request for Bid Form – 2 copies required 2. Itemized Bid Form – 2 copies required 3. Manufacturer’s brochure with detailed product information – 2 copies required 4. Vendor Information Sheet – 2 copies required 5. Taxpayer Identification Number Request – 1 copy required Payment Terms Delivery Time We claim minority bidder preference [Wis. Stats. s. 16.75(3m)]. Under Wisconsin Statutes, a 5% preference may be granted to CERTIFIED Minority Business Enterprises. Bidder must be certified by the Wisconsin Department of Development (DOD). If you have questions concerning the certification process, contact DOD, 8th Floor, 123 W. Washington Ave., Madison, Wisconsin 53702, (608) 267-9550. Does Not Apply to Printing Bids ______________________________________________________________________________________________________________________________________________________ We are a sheltered work center qualified under Wis. Stats. s. 16.752. Questions concerning the qualification process should be addressed to the Sheltered Work Center Program, State Bureau of Procurement, 6th Floor, 101 E. Wilson St., Madison, Wisconsin 53702, (608) 266-2605. ______________________________________________________________________________________________________________________________________________________ Wis. Stats. s. 16.754 directs the state to purchase materials which are manufactured to the greatest extent in the United States when all other factors are substantially equal. Materials covered in our bid were manufactured in whole or in substantial part within the United States, or the majority of the component parts thereof were manufactured in whole or in substantial part in the United States. Yes No Unknown ______________________________________________________________________________________________________________________________________________________ In signing this bid we also certify that we have not, either directly or indirectly, entered into any agreement or participated in any collusion or otherwise taken any action in restraint of free competition; that no attempt has been made to induce any other person or firm to submit or not to submit a bid; that this bid has been independently arrived at without collusion with any other bidder, competitor or potential competitor; that this bid has not been knowingly disclosed prior to the opening of bids to any other bidder or competitor; that the above statement is accurate under penalty of perjury. We will comply with all terms, conditions and specifications required by the state in this Request for Bid and all terms of our bid. Name of Authorized Company Representative (Type or Print) Signature of Above Title Date Email Federal Employer Identification # Phone ( ) Fax ( ) Social Security No. if Sole Proprietor (Voluntary) Page 1 of 19 UNIVERSITY OF WISCONSIN-PLATTEVILLE REQUEST FOR BID NO. CR-2668 TAXPAYER IDENTIFICATION NUMBER REQUEST THIS SECTION MUST BE COMPLETED AND THIS FORM RETURNED WITH YOUR BID RESPONSE Company Name (print or type) Name & Title (print or type) Signature Date Phone FAX E-mail Address Please complete the following Request for Taxpayer Identification Number and return this form with your bid to: University of Wisconsin-Platteville Purchasing Office, 2201 Ullsvik Hall 1 University Plaza Platteville WI 53818-3099 Business Name (if different from above): Check Appropriate Box: Corporation Federal Employer Identification Number - Partnership Federal Employer Identification Number - Nonprofit Organization Federal Employer Identification Number - Individual/Sole Proprietary For this category, please provide: Name (As it appears on Social Security Card) Social Security # - - Page 2 of 19 UNIVERSITY OF WISCONSIN-PLATTEVILLE REQUEST FOR BID NO. CR-2668 Vendor Information Sheet 1. BIDDING/PROPOSING COMPANY NAME FEIN Phone Toll Free Phone Fax E-Mail Address Address City 2. State Zip+4 Name the person to contact for questions concerning this bid/proposal: Name Phone Toll Free Phone Fax E-Mail Address Address City 3. State Zip+4 Any vendor awarded over $25,000 on this contract must submit affirmative action information to UW-Platteville. Please name the Personnel/Human Resource or other person responsible for affirmative action in your company we may contact about this plan. Name Phone Toll Free Phone Fax E-Mail Address Address City 4. State Zip+4 Mailing address to which state purchase orders are mailed and the person UW-Platteville may contact concerning orders/billings. Name Phone Toll Free Phone Fax E-Mail Address Address City 6. 7. State Zip+4 CEO/President Name Bidder must provide information for local service and/or repair: Name Phone Toll Free Phone Fax E-Mail Address Address City State Zip+4 Page 3 of 19 UNIVERSITY OF WISCONSIN-PLATTEVILLE BIDDER NAME: _______________________________ REQUEST FOR BID NO. CR-2668 AMENDMEND ITEMIZED BID FORM Item No. Quantity and Unit DESCRIPTION 1. 1 ea. CNC Knee Milling Machine, per the attached specifications. 2. 1 ea. CNC Vertical Milling Center, per the attached specifications. 3. 1 ea. Super Precision Toolroom Lathe, per the attached specifications. Indicate Make & Model Being Bid Unit Price Total Price LOT TOTAL Indicate that you have received, and reviewed, the amended bid document and are basing your bid submission on the amended specifications: ___ Yes, this bid reflects the amended specifications. Page 4 of 19 UNIVERSITY OF WISCONSIN-PLATTEVILLE REQUEST FOR BID NO. CR-2668 SPECIFICATIONS CNC KNEE MILLING MACHINE: Close grained Gray Cast Iron castings to ASTM Grade 30/35 Minimum hardness 187 Brinell. Federal Spec. Q-1-652. 2. Column and Dished Base casting to be one integral casting for maximum rigidity. 3. 50 Degree Vee Way System with full length Gibs adjustable with single adjustment screw 4. Hand Scraped Ways and Gibs 5. V-ram must provide 12" of rack & pinion travel with expanding dovetail locks 6. Ram Turret with ground dovetail ways and no gibs 7. Twin Knee/Column and Table/Saddle locks 8. Full 360 degrees of ram/turret rotation is required 9. Worm and gear controls must be used for angular settings of the head: 90 degrees left & right; 45 degrees front & back. 10. 9" x 48" precision ground and hand spotted machine table 11. 36" of table travel; X-axis (32.5" with power feed option allowed) 12. 12" of saddle travel, Y-axis 13. 16" of knee travel, Z-axis (Reduction of 1." with Chip Pan allowed) 14. Minimum 5" of quill travel with built-in power quill feed (.0015, .003, .006 in per revolution) Quill must also be minimum 3 1/8" dia, hard chrome plated, and hand fit for extreme accuracy and long life. Quick release micrometer depth adjustment must be included. 15. Quill must be capable of being ‘locked on’ to aid in tool changing operation 16. Drawbar system must incorporate a retaining device to prevent collar from falling inside the head of the machine 17. Maximum 750 pound table load capacity 18. Chrome/Nickel alloy spindle must be heat treated and ground on precision, preloaded bearings. 19. Quill/Spindle Assembly must have ‘clockspring’ system or equal to prevent rapid retract. 20. Adjustable vari disc pulley with Turcite bushing that does not require lubrication 21. 5 Pitch Acme Leadscrews must be centralized between the way systems 22. Backlash must be adjustable via a ‘Split Nut’ system or equal 23. Cross Slide must be covered by tight fitting way guard with a single stop screw for easy access to the knee 24. Metered, one-shot lubrication system 25. Milled oil grooves in the Saddle and Knee. Hand spotted dovetail ways on Column, Saddle, & Knee for better retention and distribution of lubricant Page 5 of 19 26. 3 HP (30 min. duty rated) Spindle Motor – Dynamically balanced – UL Listed – with Nickel Plated Motor Shaft 27. Three position motor switch – Forward/Off/Reverse 28. Solid, sealed spindle bearing cap to prevent ingress of foreign matter 29. Head Cooling system must be integral to the head design, i.e. no external fan(s) 30. R-8 spindle taper; Collet capacity 3/4" 31. Spindle guard must be included 32. Chrome plated ways to maintain inherent accuracy, plating both the angle and the flat on the - Top of the knee and top of the saddle as well as the table gibs. (.0012-.0016 minimum deposit; must exceed Rockwell C-70) 33. Chrome Plated axis leadscrews 34. Paint/Color: Castings must be filled and sanded and then painted with a minimum of two coats of two-part Polyurethane finish. Machine tool gray 35. Warranty must be at least one year for machine parts 36. OEM must have regional availability of parts, service and applications support. 37. Space & weight: ~80 x 64 x 82." Minimum 1,950 Lbs. 38. Additional Accessories & Tooling Required: 38.1 Splash-back & Chip Pan 38.2 Flood Coolant System 38.3 Work Light 38.4 Automatic Centralized Lubrication System 38.5 6” Vise (Kurt D675 or comparable) 38.6 Vise Step Key Kit 38.7 Swivel Base for Vise 38.8 Way Cover 38.9 Collet Set – 11 Pc 1/8” – ¾” in 1/16” Increments 38.10 Collet Set- 19 Pc 2mm – 20mm 38.11 Collet Trays (2 ea) 38.12 Indexer Interface 38.13 Power Drawbar 38.14 Torque Wrench 38.15 EZ Vision Software for desktop 39. CNC Control w/ following machine & control performances 39.1 Positioning Accuracy over Saddle: +/- 0.001” (+/-0.025mm) 39.2 Positioning Repeatability over saddle: +/-0.0008” (+/-0.020mm) 39.3 Input resolution: 0.0001” (0.003mm) 39.4 Servo Resolution: 0.0001” (0.003mm) 39.5 Display Resolution: 0.0001” (0.003mm) 39.6 Windows Based PC Control System: 900MHz Intel Processor 39.7 Memory Storage: 2 GB Flash Drive 39.8 Two USB Ports and Ethernet-ready 39.9 Full 3- Axis DRO 39.10 Simultaneous 2-Axis Linear or 2-Axis Circular Interpolation 39.11 12.1” Color TFT LCD Display minimum 39.12 Absolute and Incremental Programming 39.13 Automatic Corner Rounding 39.14 Mathematical Help Modes 39.15 Powerful Canned Cycles for machining arcs, diagonals, circles, bolt hole patterns, pocket milling, island pockets, ellipses etc. 39.16 Cutter Diameter Compensation Page 6 of 19 39.17 40. 2. Maintenance- Diagnostic Routines Embedded in System Installation/Training CNC VERTICAL MILLING CENTER .4” color LCD 2. CT40 3. AIAPC Contour Control 4. Work Light 5. On board PCMCIA memory card slot 6. Fully interlocked machine guarding 7. 10,000 RPM Spindle 8. Air Hose with Air Gun 9. Rigid Tapping 10. Control Specifications 10.1 8.4" Color LCD 10.2 Controlled axes 4 10.3 Least input increment - 0.001mm, 0.001deg. 10.4 Fine Acc & Dec control 10.5 Servo control HRV3 10.6 Backlash compensation 10.7 Linear interpolation 10.8 Coordinate system rotation 10.9 Cylindrical interpolation 10.10 Helical interpolation (Circular interpolation plus 10.11 Max. 2 axes linear interpolation) 10.12 Polar coordinate command 10.13 Circular interpolation (Multi-quadrant) 10.14 Mirror image 10.15 Automatic acceleration /deceleration 10.16 Rapid traverse: linear Cutting feed: exponential 10.17 Tool offset pairs, ± 6 digits, 400 pairs 10.18 Tool length compensation 10.19 Tool offset memory 10.20 Cutter compensation 10.21 Part program storage length 640 m 10.22 Number of registerable programs 400 10.23 Self-diagnosis function 10.24 Alarm history display 10.25 Operation history display 10.26 Help function 10.27 Stored pitch error compensation 10.28 Custom Macro 10.29 Tool life management 10.30 Workpiece coordinate system, G52 - G59 10.31 Addition of workpiece coordinate system 48 pairs 10.32 Automatic tool length measurement 11. General Specifications 11.1 Axis Travel Table (X axis): 18.9 in. (480mm) Saddle (Y axis): 15.8 in. (400mm) Head (Z axis): 16.9 in. (430mm) Page 7 of 19 11.2 Positioning Auto Mode (X and Y axes): 1,417 in./min. Auto Mode (Z axis): 1,417 in./min. Manual Mode (X,Y and Z axes): 0-354 in./min. Feedrate Range (X, Y and z axes): 0.1-590 in./min. Acceleration x/y/z: 190/190/190 in./ s2 Minimum Increment: 0.00004 in. Ball Screw Diameter and Pitch(X, Y): 1.26” x .629” Ball Screw Diameter and Pitch (Z): 1.26” x .472” 11.3 Spindle Spindle Speed Range: 10,000 RPM Spindle Motor HP Rating (15 min.)Fanuc: 10 hp (7.5kW) Spindle Torque 8,000 RPM (15 min.) Fanuc: 35 ft./lbs Retention Force: 1322 lbsf Spindle Taper: No. 40 Tool Holder: CT40 or BT40 Distance from table surface to Spindle Gauge Plane: 5.9” min – 22.8” 11.4 Worktable Working surface: 23.6 X 15.8 in. Min Table load: 661lbs. (300 kg) Number of T-Slots: 3 -(125mm) centers T-Slot Size: .551” (14 mm) 11.5 Control Preference Fanuc: i Series GX 11.6 Automatic Tool Changer – Drum Style Type of tool shank: BT40 or CT40 taper Magazine capacity: 16 Tools Tool Select by Shortest Path and Random Select: Bi-Directional Maximum tool diameter (Adjacent pockets): 3.7 in. (94 mm) Maximum tool diameter (With adjacent pockets): 5.11 in. (130 mm) Maximum Tool Length: 9.8 in. (249 mm) Maximum Tool Weight: 13.2 lbs. (6kg) Random Tool change time (tool to tool/c to c): 5.5/7.5 sec. 11.7 Coolant: Coolant tank capacity: 26 US gallons Min. 11.8 Accuracy Positioning: +/- 0.0002 in. (+/- 0.005mm) Repeatability: +/- 0.00008 in. (+/- 0.002mm) 11.9 Machine Size Machine height: 83 in. Max Floor space: 65 in. wide x 88 in. deep Max Mass of machine: 5,764 lbs (2,615kg) Min. 11.10 Service Requirements Electrical Supply (Input) : 208 VAC Phase: 3 Ph Cycles: 60 Hz Power: 65 FLA Compressed Air (Pressure Flow): 80 psi/4.9 cfm Nozzle Coolant : 10.5 gal/min @25 psi 11.11 Additional Accessories & Tooling Required 5C Indexer Brushless Motor & Control Manual Closer MPG Handwheel Flush coolant system Page 8 of 19 Chip washdown hose Air Blast 11.12 3. Installation/Training to be provided SUPER PRECISION LATHE 1. SCOPE: This specification covers 10-inch precision lathes having an infinitely variable high speed range, for producing both production and prototype parts to precision tolerances from a variety of materials. 1.2 Classification. The lathes covered by this specification are the following type. - Variable speeds and variable feed range, 1 horsepower rating 2. APPLICABLE DOCUMENTS – Not required 3. REQUIREMENTS 3.1 First Article. - Not required. 3.2 Design. The lathe shall be new and one of the manufacturer's current models capable of accurately producing parts in production operations and for producing prototype parts to precise dimensions in toolroom or laboratory type operations. The design shall facilitate changing feeds, speeds, and tooling. It shall be suitable for all normal lathe functions within its capacity such as turning, boring and thread cutting on ferrous and non-ferrous materials. 3.2.1 Measurement systems. The U. S. Customary System of Units (US) shall be used in the design and construction of the machine. 3.2.1.1. Measuring and indicating devices. Shall be graduated in both the U.S. and S. I. System of Measurements as follows: Dual inch/metric calibrated dials are required on the tailstock and the tool post slide. The dials on the cross slide and longitudinal axes shall be calibrated in the U.S. System of Measurement only. However, dual inch/metric graduations on the cross slide and longitudinal axes shall be provided by way of a switchable inch/metric digital readout system installed on the machine." 3.2.2 Reclaimed materials. The machine may contain reclaimed materials provided such materials will not jeopardize the machine's intended use and performance. The reclaimed materials shall have been reprocessed, remanufactured or recycled in a marmer which will restore them to the same chemical composition and physical properties as the materials originally selected for use on the machine. 3.2.3 Controls. All operating controls shall be located convenient to the operator at his normal work station. 3.2.4 Safety and health requirements. Covers, guards, or other safety devices shall be provided and the devices shall not interfere with operation of the machine. The safety devices shall prevent unintentional contact with the guarded part, and shall be removable to facilitate inspection, maintenance and repair of the parts. All machine parts, components, mechanisms and assemblies furnished on the machine, whether or not specifically required herein, shall comply with all of the requirements of OSHA 2206 that are applicable to the machine itself. In addition, the machine shall comply with all requirement of ANSI B 11.6 that are designated therein as the responsibility of the machine manufacturer. In the event of conflict between the requirements of the OSHA and ANSI Standards, the requirements of OSHA shall apply. 3.2.5 Lubrication. Means shall be provided to insure adequate lubrication for all moving parts. Each recirculating system shall include a filter which is cleanable or replaceable. Each lubricant reservoir shall have means for determining fluid level. All oil holes, grease fittings, and caps shall be accessible. 3.2.6 Interchangeability. To provide for replacement of worn parts, all parts shall be manufactured to definite dimensions and tolerances. Page 9 of 19 3.3 Construction. The machine shall be constructed of parts which are new, without defects and free of repairs. The structure shall be capable of withstanding all forces encountered during operation of the machine to its maximum rating and capacity without permanent distortion. 3.3.1 Castings and forgings. All castings and forgings shall be free of scale and mismatching. No process such as welding, peening, or filling with solder or paste shall be used for reclaiming and defective parts. 3.3.2 Welding, brazing, or soldering. Welding, brazing or soldering shall be employed only where specified in the original design. None of these operations shall be employed as a repair measure for any defective part. 3.3.3 Fastening devices. All screws, pins, bolts and similar fasteners which affect machine operation or prevent loss of fluids shall be installed with means of preventing loss of tightness. Those subject to removal or adjustment shall not be swaged, peened, staked or otherwise permanently installed. 3.3.4 Surfaces. All surfaces shall be cleaned and free of sand, dirt, fins, sprues, flash, scale, flux and other harmful or extraneous materials. All edges shall be either rounded or beveled unless sharpness is required to perform a necessary function. Except as otherwise specified herein, the condition and finish of all surfaces shall be in accordance with the manufacturer's commercial practice. 3.3.5 Painting. The machine shall be painted in accordance with the manufacturer's commercial practice. 3.3.6 Threads. All threaded parts used on the machine and its related attachments and accessories shall conform to FED-STD-H28 and the applicable “Detailed Standard" section referenced therein. 3.3.7 Dials. All dials that indicate stock removal or tool movement shall be graduated in increments not larger than 0.001 inch (U.S.) or .02mm (SI). Dial diameters shall be such that graduations may be read from the normal operating position. Dials shall be permanently and legibly engraved or etched on a non-glare background. 3.3.8 Plates. All words on instruction and indicating plates shall be in the English language. Characters shall be engraved, etched, embossed or stamped in boldface on a contrasting background. 3.3.9 Gears. All gears shall be machined from a material suitable for the intended purpose. All headstock spindle drive train gears shall be heat treated by a process that will impart the hardness and toughness that will enable the gear train to transmit full rated torque of the drive motor without gear damage, failure or premature wear. 3.4 Components. The components for the lathe shall conform to the following requirements. 3.4.1 Lathe. The lathe shall consist essentially of a cabinet mounted bed,a variable speed headstock, variable feed carriage and cross slide, quick change threading gear box, and tailstock. 3.4.1.1 Bed and base. The bed shall be a stress relieved ferrous casting designed to retain accurate way alignment. All bed way surfaces which support and guide the carriage shall have a hardness not less than Rockwell C-50. Provision shall be made for using a taper attachment. The base shall be heavy gage steel weldment or a casting providing rigid support for the lathe, and enclosing the spindle drive motor and mechanism. The top of the base shall have a chip and coolant pan designed to drain coolant into a sump. The base shall be provided with means for securing the machine on a foundation. 3.4.1.2 Headstock. The headstock shall be a variable speed belt driven unit. The variable spindle speeds shall be obtained by an electric motor driven variable speed unit. The spindle drive motor and associated drive mechanism shall be enclosed by the headstock and machine base. Speed selections shall be made by suitable controls, such as push buttons, on the headstock and a spindle speed indicator showing actual revolutions per minute. Speed adjustment shall be possible while cutting to obtain optimum feed/speed ratio under various cutting conditions. Means shall be provided to maintain proper belt tension. Provision shall be made for changing spindle drive belts without removing the spindle or losing bearing adjustment. A quick acting spindle brake shall be provided. The headstock spindle shall be the type normally provided by the builder, designed for using drawin collets, chucks and face plates. The threaded nose spindle shall be mounted in ball or roller bearings, and be operable in both forward and reverse directions of rotation. The spindle shall have Page 10 of 19 means for manual rotation and for locking during set-up. The drive unit shall be protected by an interlock to prevent power application while the spindle is locked 3.4.1.3 Carriage. The carriage, cross slide and compound slide shall be accurately fitted to mating slide ways and shall have tapered gibs to adjust for wear, The carriage and cross slide shall be operated manually and by power without sticking or chatter. The cross slide feed screws shall have a thread hardness of not less than Rockwell C-40 and shall be ground. Adjustable feed dials shall be provided to show longitudinal motion and cross motion in increments not greater than 0.001 inch, respectively or SI units as required. Way wipers shall be provided on slide units. The compound tool slide shall have a standard T-slot for mounting tool holders, shall swivel 360 degrees and have a scale graduated around the base in degree increments for angular settings. The T-slots shall meet the requirements of ANSI B5.1. The carriage apron shall be of double-wall construction supporting shafts within at both ends and enclosing the feed unit. A manually operated pressure lubricating system shall supply oil to the operating components of the carriage and to the bed ways. Lever type operating controls such as for threading and feed engagement shall fully engage and disengage with smooth positive action. 3.4.1.4 Variable power feed. Infinitely variable longitudinal and cross feeds shall be provided by a totally enclosed ball bearing type electric motor. Feed selections shall be made by a suitable control device showing chosen feeds in inches per minute, Or SI units as required, and shall be adjustable while cutting. Feeds shall be in both directions of travel of the carriage and cross slide. The power feed shall be arranged to be inoperative when the spindle is stopped, and when using the threading mechanism. Thread leads shall be provided by a totally enclosed quick change gear box and precision leadscrew which shall be reserved for thread cutting only. A combination English and metric gear box is required. Safety clutches or other suitable devices shall protect the feed mechanism from damage by accidental overload. 3.4.1.5 Tailstock. The tailstock shall be accurately fitted to the bed ways and aligned with the headstock spindle. The spindle shall have a hardness not less than Rockwell C-38 and have full bearing in the tail stock. The spindle feed mechanism shall extend and retract the spindle to both limits of travel without binding. The spindle handwheel shall have a feed dial graduated in increments of 0.001 inch or less, and SI units as required. The spindle shall hold taper shank tools, and the tool shall be disengageable from the taper by full retraction of the spindle. Means shall be provided to lock the tailstock in position on the bed, and to lock the spindle in any extended position without affecting alignment. 3.4.2 Coolant system. The coolant system shall include a sump or reservoir, a power driven pump, and all necessary piping. The sump or reservoir shall have sufficient capacity to permit full flow of coolant. The system shall have means for draining and cleaning. Means shall be provided to permit the operator to direct and control the amount of coolant. 3.4.3 Electric system. The electrical system shall conform to all requirements in this paragraph. The system shall conform to the requirements of ANSI/NFPA No. 79. The machine shall draw all of its electrical power from a single 208 volt, 3 phase, 60 Hz circuit. The machine shall be initially wired for operation on 208 volts. An identified terminal for grounding the machine when installed shall be mounted in or near the disconnect switch. 3.4.4 Motors. Motors shall have ball or roller bearings. Continuous duty power ratings shall conform to the requirements of table I. Each motor enclosure shall meet the requirements for a drip-proof enclosure. 3.5 Sizes and capacities. The sizes and capacities of the machine shall meet the requirements of table I. TABLE I Sizes and capacities. Machine Characteristic Type I Capacities: Swing over bed Swing over Cross slide II" 6" Page 11 of 19 Distance between centers (tailstock fully supported) Main drive motor 18" 1 HP Headstock: Spindle type and size Hole through spindle Center size, M.T. Mfr's Std. 1 1/4" Mfr's Std. Draw-bar collet capacity,round stock 1 1/16" Optional spindle nose collet, chuck Spindle speed range, variable, r.p.m. 125 to 3,000 Carriage: Cross Slide travel Compound slide travel Gear box, English Number of feeds Feed range Number of threads Thread range 5-1/2” 3” Variable 1/4 to 7IPM 27 11 to 108 Leadscrew diameter and threads per inch Gear box, Combination English and Metric Feed range English Metric Number of threads English/Metric Range of threads – English/Metric Lead Screw diameter and threads per inch Tailstock: Spindle diameter Spindle travel Center Size, M.T. 1”, 8TPI 5/16 to 7 IPM 8 to 176mm/pm 36/36 11-108 In /.275-2.7mm I" 8TPI 1 3/8” 3-1/2” #2 3..6 Performance. Machine and components, operator's controls and safety devices shall function properly when tested n accordance with 4.5.1 thru 4.5.3. 3.7 Alignment tolerances. Lathe accuracies shall be within the tolerances of table II when checked in accordance with 4.5.2. TABLE II Alignment Tolerances (Dimensions in Inches) Test Type I Tolerance Spindle center runout 0.0002 TIR Spindle nose runout, External taper surface Internal taper surface 0.000025 TIR 0.000025 TIR Spindle face runout, chuck seat surface Spindle alignment with bed ways, Vertical w/12" test bar Horizontal w/12" test bar 0.000025 TIR 0.0004 0.0002 Page 12 of 19 Spindle rotational accuracy Axial runout Radial runout 0.000025 TIR 0.000024 TIR Headstock and tail stock center, alignment, high at tailstock end of bar 0.001 Total Leadscrew cam action 0.0002 Leadscrew lead error +0.001 in 12" +0.0004 in 4" Leadscrew, alignment with ways, Horizontal and Vertical alignment 0.003 Max Cross feed screw backlash 0.002 Cross slide alignment square with spindle axis, concave 0.0005 in 9” diameter 3.8 Standard equipment. Each lathe shall be furnished with all standard equipment normally furnished by the machine manufacturer. The equipment specified in 3.8.1 shall be supplied as additional accessories. 3.8.1 Acu-Rite Digital readout (DRO) Taper Turning Attachment Work Light Steady Rest Follow Rest Tool Holder Base Cut Off Holder Knurl Tool Holder Knurl Tool Assembly Single Tool Holders (2 Ea) Single Tool Holder Assy Multi Tool Holder Shank Tool Holders (2 Ea) 1/16’ Cut Off Blade 3/32” Cut Off Blade 1/8” Cut Off Blade Heavy Duty Live Center Light Duty Live Center Chuck 5” 3 Jaw Threaded Chuck 6” 2 Jaw Threaded Chuck 6” 3 Jaw Threaded Chuck 6” 4 Jaw Threaded Drill Chuck – 1/8” Capacity Drill Chuck – 3/8” Capacity Drill Chuck - ½” Capacity 5C - 64 Pc Collet Set 5C – Blank Collet – no pilot hole 5C – Emergency Collet 1/16” Pilot Hole 5C – Brass Emergency Collet 1/16” Pilot Hole 5C – Emergency Collet 1/8” Pilot Hole 5C – Brass Emergency Collet 1/8” Pilot Hole 5C – Brass Emergency Collet no pilot hole Head Stock Live Centers Drive Plate – Threaded 9” Face Plate – Threaded Drive Dog Page 13 of 19 Longitudinal Four Barrel position stop w/ hardened stop plate 3.9 Digital Readout. Switchable inch/metric digital readout system for x and y axes required. Graduations shall be a minimum of .00005” on X axis and a minimum of .00010” on Z axis. 3.10 Lubrication chart or plate. Not Required 3.11 Identification. Lathe to be clearly marked with the following information; Manufacturer's model designation Manufacturer's serial number Motor Size_ horsepower_ Power input (volts, total amps, phase, frequency) 3.12 Technical data. Required technical data, such as operator's manuals, parts lists, foundation and anchor bolt plans, wiring diagrams and other instructions for operation and maintenance are to be included. 3.13 Workmanship. Workmanship of the machine and accessories shall be of a quality equal to that of the manufacturer's commercial equipment of the type specified herein. 4. QUALITY ASSURANCE PROVISIONS 4.1 Responsibility for inspection. Unless otherwise specified in the contract, the contractor is responsible for the performance of all inspection requirements as specified herein. Except as otherwise specified in the contract, the contractor may use his own or any other facilities suitable for the performance of the inspection requirements specified herein. The purchaser reserves the right to perform any of the inspections set forth in the specification where such inspections are deemed necessary to assure supplies and services conform to prescribed requirements. 4.2 First article inspection. Not required. 4.3 Quality conformance inspection. Not required. 4.4 Examination. The machine and equipment shall be examined for compliance with the requirements of this specification in 3.2 through 3.5. 4.5 Test - Installation & Training . 4.6 5. 4.5.1 Operational test. The machine shall be operated at no load for not less than 60 minutes. Proper operation of all controls, motors, adjusting mechanism and accessories shall be verified during the trial period. 4.5.2 Alignment tolerance test. The machine shall be checked in accordance with the builder's standard test methods, using test instruments of his choice to accurately determine that the assembled machine is within the tolerances specified in 3.7. 4.5.3 Installation & Training. To be provided Packaging inspection. Packaging shall be inspected to determine compliance with the requirements of Section 5. PACKAGING 5.1 PACKAGING. Manufacturer's standard commercial packaging. Packing and marking required. In addition, mark "Not for Outside Storage". 6. NOTES 6.1 Intended use. The lathes covered by this specification are intended for use in production shops, tool rooms and laboratories where the nature of the work requires extreme Accuracy, fine surface finish and high speeds for turning, facing, boring, and threading operations on various materials using modern cutting tools such as carbide and ceramics. Page 14 of 19 UNIVERSITY OF WISCONSIN-PLATTEVILLE REQUEST FOR BID NO. CR-2668 SPECIAL CONDITIONS OF BID 1. F.O.B. DESTINATION: Bid prices should be F.O.B. DESTINATION, our dock at Central Receiving at the University of WisconsinPlatteville. Prices are to include all packing, transportation and insurance charges. If bidding other than F.O.B. Destination, as stated above, F.O.B. point and shipping charges should be identified in your bid. This cost will be added to the bid total for determining award. Failure to identify shipping point and shipping charges will result in the University refusing to pay any associated shipping costs. 2. METHOD OF BID: Bidders shall submit a unit price and extended total for each item, and total price by lot as designated. Complete and return the following: 2.1 Request for Bid Form – two copies required 2.2 Itemized Bid List pages – two copies required 2.3 Manufacturer’s brochure with detailed product information – two copies required 2.4 Vendor Information Sheet – two copies required 2.5 Taxpayer Identification Number Request – one copy required 3. BID SUBMISSION: Bidders shall submit a written bid, using the forms provided, in a sealed envelope, and carrying the bidder's name and address. Bidders shall include the following information on the outside of the bid envelope or package: 3.1 Request for bid number 3.2 Date of opening 3.3 Time of opening 3.4 Description of commodity or service for which the bid is submitted 4. FAX BIDS: FAX bids are acceptable by UW-Platteville; it is your option. Faxed bids will be rejected if they are not received in the Purchasing Office on time. You may FAX your bid to the attention of Carol Rauch at 608-342-1222. 4.1 All faxed bid responses will have a facsimile transmission cover letter which includes: a. Date b. Agency fax number c. Agency name d. Agency contact person and telephone number e. Bidder fax number (if available) f. Bidder name g. Bidder contact person and telephone number h. Number of pages (including cover) being transmitted 4.2 Faxed replies to bid requests will be signed. Each page will be initialed and numbered "page 1 of 5, page 2 Page 15 of 19 of 5," etc. 4.3 5. Faxed bids will be rejected if they do not arrive on time, i.e., the last page of the fax transmission must be completed prior to the bid opening due date and time. It is the bidder’s responsibility to ensure the faxed bid has been received by the Purchasing Office. METHOD OF AWARD Award shall be made on the basis of the lowest lot total price that is judged to be in the best interest of the University of Wisconsin System. 6. ELIGIBLE PURCHASERS: Successful bidder shall be required to offer the entire contract conditions and pricing to other UW-Campuses without exceptions. 7. PRODUCT INFORMATION Please be advised that the following equipment as provided by Hardinge Bridgeport is known to meet the attached specifications: Item No. 1 – Bridgeport EZ Vision Series I Milling Machine Item No. 2 – Hardinge/Bridgeport GX 480P3 Vertical Milling Machine #VMC480P3 Item No. 3 – Hardinge HLV Super Precision Lathe Specific manufacturer and model information is provided for comparison purposes only. Bids must clearly identify the manufacturer and catalog or stock number. UW-Platteville will be the sole judge of acceptability. 8. BIDDER INFORMATION The State of Wisconsin’s purchasing information and vendor notification service is available to all businesses and organizations that want to sell to the state. Anyone may access VendorNet on the Internet at http://vendornet.state.wi.us to get information on state purchasing practices and policies, goods and services that the state buys, and tips on selling to the state. Vendors may use the same Web site address for inclusion on the bidders list for goods and services that the organization wants to sell to the state. A subscription with notification guarantees the organization will receive an e-mail message each time a state agency, including any campus of the University of Wisconsin System, posts a request for bid or a request for proposal in their designated commodity/service area(s) with an estimated value over $25,000. Organizations without Internet access receive paper copies in the mail. Increasingly, state agencies also are using VendorNet to post simplified bids valued at $25,000 or less. Vendors also may receive e-mail notices of these simplified bid opportunities. 9. ADDITIONAL INFORMATION: Technical questions regarding this bid should be directed to Clyde Holverson at telephone number 608-342-1334. Questions regarding the bidding process should be directed to Carol Rauch at telephone 608-342-1221. Page 16 of 19 Wisconsin Department of Administration Chs. 16, 19, 51 DOA-3054 (R01/2001) Page 1 of 3 Standard Terms And Conditions (Request For Bids / Proposals) 1.0 SPECIFICATIONS: The specifications in this request are the minimum acceptable. When specific manufacturer and model numbers are used, they are to establish a design, type of construction, quality, functional capability and/or performance level desired. When alternates are bid/proposed, they must be identified by manufacturer, stock number, and such other information necessary to establish equivalency. The State of Wisconsin shall be the sole judge of equivalency. Bidders/proposers are cautioned to avoid bidding alternates to the specifications which may result in rejection of their bid/proposal. 2.0 DEVIATIONS AND EXCEPTIONS: Deviations and exceptions from original text, terms, conditions, or specifications shall be described fully, on the bidder's/proposer's letterhead, signed, and attached to the request. In the absence of such statement, the bid/proposal shall be accepted as in strict compliance with all terms, conditions, and specifications and the bidders/proposers shall be held liable. 3.0 QUALITY: Unless otherwise indicated in the request, all material shall be first quality. Items which are used, demonstrators, obsolete, seconds, or which have been discontinued are unacceptable without prior written approval by the State of Wisconsin. 4.0 QUANTITIES: The quantities shown on this request are based on estimated needs. The state reserves the right to increase or decrease quantities to meet actual needs. 5.0 DELIVERY: Deliveries shall be F.O.B. destination freight prepaid and included unless otherwise specified. 6.0 PRICING AND DISCOUNT: The State of Wisconsin qualifies for governmental discounts and its educational institutions also qualify for educational discounts. Unit prices shall reflect these discounts. 6.1 Unit prices shown on the bid/proposal or contract shall be the price per unit of sale (e.g., gal., cs., doz., ea.) as s tated on the request or contract. For any given item, the quantity multiplied by the unit price shall establish the extended price, the unit price shall govern in the bid/proposal evaluation and contract administration. 6.2 Prices established in continuing agreements and term contracts may be lowered due to general market conditions, but prices shall not be subject to increase for ninety (90) calendar days from the date of award. Any increase proposed shall be submitted to the contracting agency thirty (30) calendar days before the proposed effective date of the price increase, and shall be limited to fully documented cost increases to the contractor which are demonstrated to be industrywide. The conditions under which price increases may be granted shall be expressed in bid/proposal documents and contracts or agreements. 6.3 In determination of award, discounts for early payment will only be considered when all other conditions are equal and when payment terms allow at least fifteen (15) days, providing the discount terms are deemed favorable. All payment terms must allow the option of net thirty (30). 7.0 UNFAIR SALES ACT: Prices quoted to the State of Wisconsin are not governed by the Unfair Sales Act. 8.0 ACCEPTANCE-REJECTION: The State of Wisconsin reserves the right to accept or reject any or all bids/proposals, to waive any technicality in any bid/proposal submitted, and to accept any part of a bid/proposal as deemed to be in the best interests of the State of Wisconsin. Bids/proposals MUST be date and time stamped by the soliciting purchasing office on or before the date and time that the bid/proposal is due. Bids/proposals date and time stamped in another office will be rejected. Receipt of a bid/proposal by the mail system does not constitute receipt of a bid/proposal by the purchasing office. 9.0 METHOD OF AWARD: Award shall be made to the lowest responsible, responsive bidder unless otherwise specified. 10.0 ORDERING: Purchase orders or releases via purchasing cards shall be placed directly to the contractor by an authorized agency. No other purchase orders are authorized. 11.0 PAYMENT TERMS AND INVOICING: The State of Wisconsin normally will pay properly submitted vendor invoices within thirty (30) days of receipt providing goods and/or services have been delivered, installed (if required), and accepted as specified. Invoices presented for payment must be submitted in accordance with instructions contained on the purchase order including reference to purchase order number and submittal to the correct address for processing. A good faith dispute creates an exception to prompt payment. 12.0 TAXES: The State of Wisconsin and its agencies are exempt from payment of all federal tax and Wisconsin state and local taxes on its purchases except Wisconsin excise taxes as described below. The State of Wisconsin, including all its agencies, is required to pay the Wisconsin excise or occupation tax on its purchase of beer, liquor, wine, cigarettes, tobacco products, motor vehicle fuel and general aviation fuel. However, it is exempt from payment of Wisconsin sales or use tax on its purchases. The State of Wisconsin may be subject to other states' taxes on its purchases in that state depending on the laws of that state. Contractors performing construction activities are required to pay state use tax on the cost of materials. Page 17 of 19 13.0 14.0 GUARANTEED DELIVERY: Failure of the contractor to adhere to delivery schedules as specified or to promptly replace rejected materials shall render the contractor liable for all costs in excess of the contract price when alternate procurement is necessary. Excess costs shall include the administrative costs. ENTIRE AGREEMENT: These Standard Terms and Conditions shall apply to any contract or order awarded as a result of this request except where special requirements are stated elsewhere in the request; in such cases, the special requirements shall apply. Further, the written contract and/or order with referenced parts and attachments shall constitute the entire agreement and no other terms and conditions in any document, acceptance, or acknowledgment shall be effective or binding unless expressly agreed to in writing by the contracting authority. 15.0 APPLICABLE LAW: This contract shall be governed under the laws of the State of Wisconsin. The contractor shall at all times comply with and observe all federal and state laws, local laws, ordinances, and regulations which are in effect during the period of this contract and which in any manner affect the work or its conduct. The State of Wisconsin reserves the right to cancel any contract with a federally debarred contractor or a contractor which is presently identified on the list of parties excluded from federal procurement and nonprocurement contracts. 16.0 ANTITRUST ASSIGNMENT: The contractor and the State of Wisconsin recognize that in actual economic practice, overcharges resulting from antitrust violations are in fact usually borne by the State of Wisconsin (purchaser). Therefore, the contractor hereby assigns to the State of Wisconsin any and all claims for such overcharges as to goods, materials or services purchased in connection with this contract. 17.0 ASSIGNMENT: No right or duty in whole or in part of the contractor under this contract may be assigned or delegated without the prior written consent of the State of Wisconsin. 18.0 WORK CENTER CRITERIA: A work center must be certified under s. 16.752, Wis. Stats., and must ensure that when engaged in the production of materials, supplies or equipment or the performance of contractual services, not less than seventy-five percent (75%) of the total hours of direct labor are performed by severely handicapped individuals. 19.0 NONDISCRIMINATION / AFFIRMATIVE ACTION: In connection with the performance of work under this contract, the contractor agrees not to discriminate against any employee or applicant for employment because of age, race, religion, color, handicap, sex, physical condition, developmental disability as defined in s. 51.01(5), Wis. Stats., sexual orientation as defined in s. 111.32(13m), Wis. Stats., or national origin. This provision shall include, but not be limited to, the following: employment, upgrading, demotion or transfer; recruitment or recruitment advertising; layoff or termination; rates of pay or other forms of compensation; and selection for training, including apprenticeship. Except with respect to sexual orientation, the contractor further agrees to take affirmative action to ensure equal employment opportunities. 19.1 Contracts estimated to be over twenty-five thousand dollars ($25,000) require the submission of a written affirmative action plan by the contractor. An exemption occurs from this requirement if the contractor has a workforce of less than twenty-five (25) employees. Within fifteen (15) working days after the contract is awarded, the contractor must submit the plan to the contracting state agency for approval. Instructions on preparing the plan and technical assistance regarding this clause are available from the contracting state agency. 19.2 The contractor agrees to post in conspicuous places, available for employees and applicants for employment, a notice to be provided by the contracting state agency that sets forth the provisions of the State of Wisconsin's nondiscrimination law. 19.3 Failure to comply with the conditions of this clause may result in the contractor's becoming declared an "ineligible" contractor, termination of the contract, or withholding of payment. 20.0 PATENT INFRINGEMENT: The contractor selling to the State of Wisconsin the articles described herein guarantees the articles were manufactured or produced in accordance with applicable federal labor laws. Further, that the sale or use of the articles described herein will not infringe any United States patent. The contractor covenants that it will at its own expense defend every suit which shall be brought against the State of Wisconsin (provided that such contractor is promptly notified of such suit, and all papers therein are delivered to it) for any alleged infringement of any patent by reason of the sale or use of such articles, and agrees that it will pay all costs, damages, and profits recoverable in any such suit. 21.0 SAFETY REQUIREMENTS: All materials, equipment, and supplies provided to the State of Wisconsin must comply fully with all safety requirements as set forth by the Wisconsin Administrative Code, the Rules of the Industrial Commission on Safety, and all applicable OSHA Standards. 22.0 WARRANTY: Unless otherwise specifically stated by the bidder/proposer, equipment purchased as a result of this request shall be warranted against defects by the bidder/proposer for one (1) year from date of receipt. The equipment manufacturer's standard warranty shall apply as a minimum and must be honored by the contractor. 23.0 INSURANCE RESPONSIBILITY: The contractor performing services for the State of Wisconsin shall: 23.1 Maintain worker's compensation insurance as required by Wisconsin Statutes, for all employees engaged in the work. 23.2 Maintain commercial liability, bodily injury and property damage insurance against any claim(s) which might occur in carrying out this agreement/contract. Minimum coverage shall be one million dollars ($1,000,000) liability for bodily injury and property damage including products liability and completed operations. Provide motor vehicle insurance for all owned, non-owned and hired vehicles that are used in carrying out this contract. Minimum coverage shall be one million dollars ($1,000,000) per occurrence combined single limit for automobile liability and property damage. 23.3 The state reserves the right to require higher or lower limits where warranted. Page 18 of 19 24.0 CANCELLATION: The State of Wisconsin reserves the right to cancel any contract in whole or in part without penalty due to nonappropriation of funds or for failure of the contractor to comply with terms, conditions, and specifications of this contract. 25.0 VENDOR TAX DELINQUENCY: Vendors who have a delinquent Wisconsin tax liability may have their payments offset by the State of Wisconsin. 26.0 PUBLIC RECORDS ACCESS: It is the intention of the state to maintain an open and public process in the solicitation, submission, review, and approval of procurement activities. Bid/proposal openings are public unless otherwise specified. Records may not be available for public inspection prior to issuance of the notice of intent to award or the award of the contract. 27.0 28.0 PROPRIETARY INFORMATION: Any restrictions on the use of data contained within a request, must be clearly stated in the bid/proposal itself. Proprietary information submitted in response to a request will be handled in accordance with applicabl e State of Wisconsin procurement regulations and the Wisconsin public records law. Proprietary restrictions normally are not accepted. However, when accepted, it is the vendor's responsibility to defend the determination in the event of an appeal or litigation. 27.1 Data contained in a bid/proposal, all documentation provided therein, and innovations developed as a result of the contracted commodities or services cannot by copyrighted or patented. All data, documentation, and innovations become the property of the State of Wisconsin. 27.2 Any material submitted by the vendor in response to this request that the vendor considers confidential and proprietary information and which qualifies as a trade secret, as provided in s. 19.36(5), Wis. Stats., or material which can be kept confidential under the Wisconsin public records law, must be identified on a Designation of Confidential and Proprietary Information form (DOA-3027). Bidders/proposers may request the form if it is not part of the Request for Bid/Request for Proposal package. Bid/proposal prices cannot be held confidential. DISCLOSURE: If a state public official (s. 19.42, Wis. Stats.), a member of a state public official's immediate family, or any organization in which a state public official or a member of the official's immediate family owns or controls a ten percent (10%) interest, is a party to this agreement, and if this agreement involves payment of more than three thousand dollars ($3,000) within a twelve (12) month period, this contract is voidable by the state unless appropriate disclosure is made according to s. 19.45(6), Wis. Stats., before signing the contract. Disclosure must be made to the State of Wisconsin Ethics Board, 44 East Mifflin Street, Suite 601, Madison, Wisconsin 53703 (Telephone 608-266-8123). State classified and former employees and certain University of Wisconsin faculty/staff are subject to separate disclosure requirements, s. 16.417, Wis. Stats. 29.0 RECYCLED MATERIALS: The State of Wisconsin is required to purchase products incorporating recycled materials whenever technically and economically feasible. Bidders are encouraged to bid products with recycled content which meet specifications. 30.0 MATERIAL SAFETY DATA SHEET: If any item(s) on an order(s) resulting from this award(s) is a hazardous chemical, as defined under 29CFR 1910.1200, provide one (1) copy of a Material Safety Data Sheet for each item with the shipped container(s) and one (1) copy with the invoice(s). 31.0 PROMOTIONAL ADVERTISING / NEWS RELEASES: Reference to or use of the State of Wisconsin, any of its departments, agencies or other subunits, or any state official or employee for commercial promotion is prohibited. News releases pertaining to this procurement shall not be made without prior approval of the State of Wisconsin. Release of broadcast e-mails pertaining to this procurement shall not be made without prior written authorization of the contracting agency. 32.0 HOLD HARMLESS: The contractor will indemnify and save harmless the State of Wisconsin and all of its officers, agents and employees from all suits, actions, or claims of any character brought for or on account of any injuries or damages received by any persons or property resulting from the operations of the contractor, or of any of its contractors, in prosecuting work under this agreement. 33.0 FOREIGN CORPORATION: A foreign corporation (any corporation other than a Wisconsin corporation) which becomes a party to this Agreement is required to conform to all the requirements of Chapter 180, Wis. Stats., relating to a foreign corporation and must possess a certificate of authority from the Wisconsin Department of Financial Institutions, unless the corporation is transacting business in interstate commerce or is otherwise exempt from the requirement of obtaining a certificate of authority. Any foreign corporation which desires to apply for a certificate of authority should contact the Department of Financial Institutions, Division of Corporation, P. O. Box 7846, Madison, WI 53707-7846; telephone (608) 266-3590. Page 19 of 19