Hatem Mohamed

advertisement

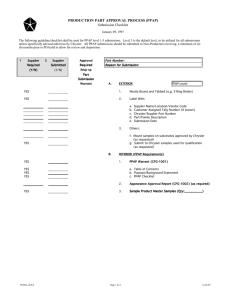

Hatem Mohamed hatem.mohamed@bmw-eg.com Cairo- Egypt Tel: 016-2000001 EDUCATION AND CERTIFICATIONS Ph.D., Mechanical Engineering, In process University of South Carolina, Columbia, SC, USA M.S., Integrated Manufacturing Systems Engineering, May 1998 North Carolina State University, Raleigh, NC, USA B.S., Mechanical Engineering, December 1995 Cairo University, Cairo, Egypt SIX-SIGMA Green belt, John Deere Certified Lead Assessor, IRCA registered. Certified Trainer, Lloyd’s Register Internal Auditor Certification Certified 5’S Champion Advanced Supervision certification Supervision Certification SIX-SIGMA Black belt (In process) COMPUTER SKILLS MS (Word, EXCEL, PowerPoint, Access, Project), Lotus 123, VISIO, RCM UNIX, VAX, Windows NT, Windows2000 AutoCAD, Unigraphics, Pro-E, Factory CAD, Factory Flow, Factory Plan SAP R/3, Profit Key, JBA, COPIX, Metaphase, Intuitive Statgraphics, Minitab, S-Plus C, HTML, JavaScript, Visual Basic, Siman-Arena, MPX PROFESSIONAL EXPERIENCE Bavarian Auto Group (Cairo- Egypt) 9/07 to Present Assembler of BMW-Brilliance-Mahindra automobile Supplier Development & Quality Assurance Manager Main responsibilities include: Manage the supplier development engineering team to ensure effective implementation of BMAC localization strategy. Approve potential local suppliers in the strategic sourcing initiatives. Budgeting of local content supplier projects including FTG, manufacturing processes, packaging, etc. Ensure local content items, including parts, FTG, are within project proposed budget. Continually work on minimizing local content costing. This would include FTG, packaging, manufacturing processes. Facilitate the IDA approval process with local suppliers. Manage Advanced Quality Planning (AQP), Production Part Approval Process (PPAP) implementation activities. Review and re-evaluate suppliers performance Ensure that technical changes from OEM are communicated properly both internally and externally and associated databases are updated. Manage all local item release process. Ensure effective corrective and preventive action is in place to address local supplier issues. Create and drive improvement plans for local content supplier to ensure continuous improvement. Lloyd’s Register (Dubai, UAE) 3/06 to 9/2007 Lead Assessor and Trainer Main responsibility is to conduct assessment and certify organization for the Quality Management System ISO9001:2000. Organizations include wide variety of services business segmentation. Also, conducting training sessions in variety of topics such as, Internal audit, ISO appreciation, Certified Lead Assessor, Performance Management, etc. John Deere, USA 6/03 to 11/05 Supplier Development Engineer Main responsibility is to develop suppliers to meet John Deere expectations. That includes defining the gap between supplier’s performance and John Deere expectations. I have worked with many suppliers in all operations aspects such as Capacity Planning, Quality Assurance, Predictive Maintenance Programs, Facility Layout, New Product Introduction, Logistics, and Continuous Improvement. Also responsibilities include: Administrate PPAP&APQP Certify suppliers and audit quality system. Support production line quality issues ISO procedures compliant, testing and implementing quality plans Capability study analysis, DOE, ECR initiations Design reviews John Deere, USA 1/01 to 5/02 Quality/manufacturing Engineer Supervised a production line with 18 workers. Applied Kaizen and JIT techniques which improved productivity by 45% Implemented new layout for the MP Saw line. That includes line balance, OMS, equipment setup Applied Kaizen technique in shipping and Receiving Dept. PPAP & APQP. Continuous improvement projects in weld area which resulted in scrap rate reduction of 65% 5S Team champion. Led several 5S activities to promote Visual Work Place. Supplier Certification Coordinator, AE Program Working on suppliers audit and certification. Collecting data for suppliers’ evaluation. PPAP, APQP, 8D administrator Preparing data entry into SAP Inventory and cycle counter supervisor Supervised Inventory Control Department including 4 personnel. Managed inventory control activities including cycle counting, and adjustment. Review all cycle counting transaction in SAP. North Carolina State University & Anderson Consulting, USA Consultant Engineer Projects include: Waste reduction Process mapping to improve productivity 9/97 to 9/00 JIT production practice Mistake proof operations (Poka-Yok) Layout redesign and simulation Kaizen Continuous improvement projects Companies includes Duff-Norton, Square-D, Carolina Builders, Night-Dale Electronics PROFESSIONAL SOCIETIES ASME-American Society of Mechanical Engineers ASEE-American Society for Engineering Education SME-Society of Manufacturing Engineers ASQ-American Society for Quality Tau Beta Pi-Engineering Honor Society