MSSC Test Prepartion Sample Questions

advertisement

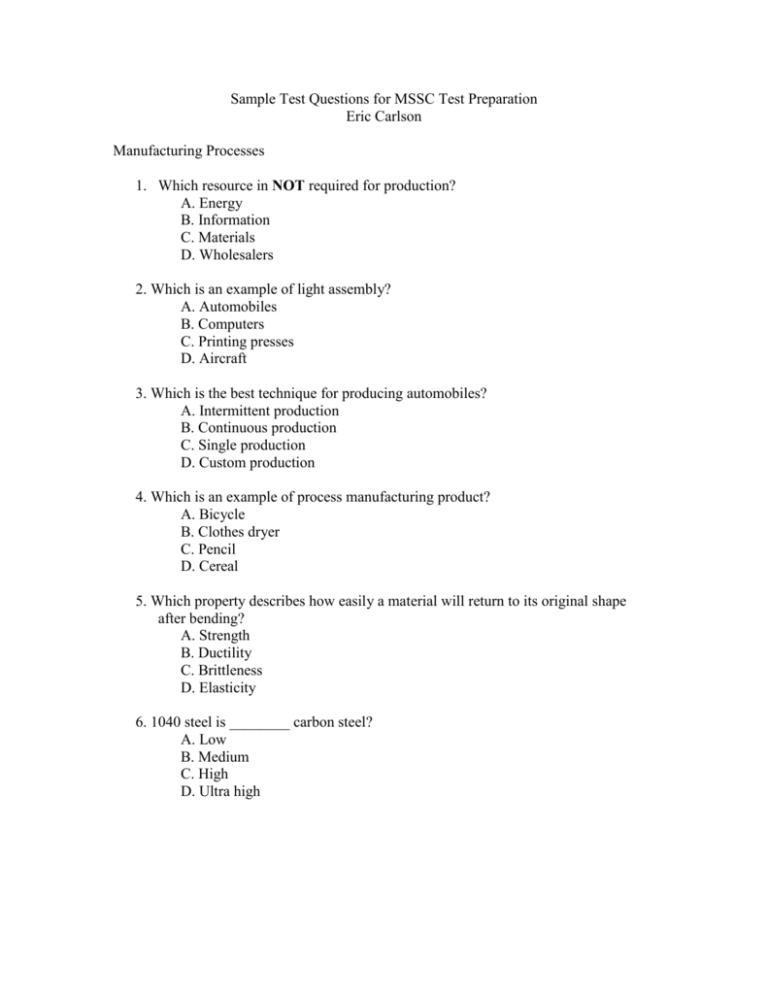

Sample Test Questions for MSSC Test Preparation Eric Carlson Manufacturing Processes 1. Which resource in NOT required for production? A. Energy B. Information C. Materials D. Wholesalers 2. Which is an example of light assembly? A. Automobiles B. Computers C. Printing presses D. Aircraft 3. Which is the best technique for producing automobiles? A. Intermittent production B. Continuous production C. Single production D. Custom production 4. Which is an example of process manufacturing product? A. Bicycle B. Clothes dryer C. Pencil D. Cereal 5. Which property describes how easily a material will return to its original shape after bending? A. Strength B. Ductility C. Brittleness D. Elasticity 6. 1040 steel is ________ carbon steel? A. Low B. Medium C. High D. Ultra high 7. Which of the following is a ferrous metal? A. Cast iron B. Titanium C. Gold D. Brass 8. The main element of bronze is… A. Iron B. Copper C. Lead D. Aluminum 9. Which is NOT a characteristic of wood products? A. Flammability B. A grain pattern C. Unaffected by moisture D. Strength 10. Which is NOT natural polymer? A. Wood B. Cotton C. Rubber D. Plastic 11. Which is an example of an organic chemical? A. Ammonia B. Sulfuric acid C. Chlorine D. Ethylene 12. Which is NOT a type of casting? A. Investment B. Die C. Sand D. Forging 13. Which type of equipment is used to create cylindrical parts? A. Saw B. Milling machine C. Drilling machine D. Lathe 14. The acronym “CNC” represents? A. Computer Numerical Control B. Constant Noise Control C. Computational Nuisance Control D. Constant Number Computing 15. Nanomaterials are… A. Materials which are flammable B. Extremely heavy metals C. Only used in the production of food D. Materials created at an atom by atom level 16. The following is an example of a smart material… A. Shape memory alloy B. Titanium C. Ultra hard steel D. Graphite composite 17. The following is NOT an example of a forming process… A. Stamping B. Extruding C. Closed-die forging D. Die casting 18. All of the following are examples of machining except… A. Drilling B. Compression molding C. Milling D. Broaching 19. Which of the following is considered an advanced machining process? A. Injection molding B. Hydroforming C. Turning D. Electrochemical machining 20. Centrifuging is defined by… A. A distillation process that separates liquid by heating B. A process of spinning materials to separate particles C. A process which uses weights to squeeze out liquid D. A process which uses filters to separate particles 21. Which describes metal milling process? A. The workpiece is rotated into the cutter B. A long thin multi-tooth blade is passed over the work C. Abrasive is shot at the work at high speeds D. A rotating cutter is applied to the workpiece 22. Which process is used to bring metal is a soft state? A. Tempering B. Hardening C. Heat treating D. Annealing 23. Which is NOT an example of a coating surface? A. Dipping B. Electropolishing C. Painting D. Anodizing 24. A part needs to measured on its diameter to resolution of 0.0001. Your measuring tool of choice is… A. Vernier protractor B. Steel rule C. Vernier caliper D. Vernier micrometer 25. A Gantt chart is used to… A. Predict when equipment will fail B. Determine the best manufacturing process C. Determine root cause analysis D. Schedule resources for production Safety Practices 1. Which type of fire extinguisher should be used on a grease, oil or chemical fire? A. Class A B. Class B C. Class C D. Class D 2. Electrical shock is NOT dependent on the following factor? A. Wetness of the skin B. Length of contact C. Grounding of the individual D. Amount of voltage 3. When using a fire extinguisher, the PASS technique stands for? A. Pull pin, Assess, Squeeze lever, Seal the area. B. Pull pin, Aim low, Squeeze lever, Sweep the hose. C. Pull pin, Align, Sweep the area, Shake the extinguisher. D. Pull pin, Aim up, Sweep the area, Sweep the fire. 4. Employers are required to report workplace injuries to? A. FCC B. EPA C. NIOSH D. OSHA 5. Which of the following is not an example of Personal Protective Equipment? A. Hard hat B. Respirator C. Safety checklist D. Steel-toed boots 6. Approximately how many eye injuries occur in the workplace every day? A. 50 B. 300 C. 600 D. 1000 7. Which of the following should NOT be worn when operating rotating equipment such as drill presses and lathes? A. Steel-toed boots B. Gloves C. Eye protection D. Ear plugs 8. ESD (Electrostatic Discharge) is dangerous because… A. It can damage electronics B. It can cause an explosion C. It can cause nerve damage D. It can cause a bright arc 9. Which safety color is used to identify information and caution? A. Orange B. Red C. Yellow D. Blue 10. Fall protection must be used on scaffolding above which height? A. 6 feet B. 10 feet C. 15 feet D. 20 feet 11. Pits deeper than _____ are considered confined spaces. A. 4 B. 10 C. 15 D. 20 12. How far away must flammable and combustible material be kept away from hot work? A. 10 feet B. 20 feet C. 35 feet D. 50 feet 13. Which is NOT considered “hot work”? A. Grinding B. Welding C. Flame Cutting D. Filing 14. Which of the following hazardous substances has no odor? A. Gasoline B. Propane C. Ammonia D. Carbon monoxide 15. Which of the following is not a biological hazard? A. Viruses B. Fungi C. Bacteria D. Sodium hydroxide 16. What distance must be kept between stored oxygen and acetylene cylinders? A. 5 feet B. 10 feet C. 15 feet D. 20 feet 17. The acronym “MSDS” represents… A. Maximum Safety Disposal Standard B. Material Standard Disposal Steps C. Minimum Safe Distance Standards D. Material Safety Data Sheet 18. If a worker is found unconscious the following should NOT be done… A. Check the area for hazards B. Keep the person lying down C. Give the person water D. Call 911 or the nearest medical facility 19. Fire extinguisher and first-aid kit locations should be shown… A. After a worker is trained for safety in that area B. Only for the worker’s area C. After the probationary period D. During new employee tours 20. Which is NOT an example of an engineered safety control? A. Circuit breakers B. Machine guards C. Ventilation systems D. Safety glasses 21. “EPA” is the acronym for? A. Extra Protection Area B. Electrical Pulse Area C. Environmental Protection Analysis D. Environmental Protection Agency 22. Safety practices can accomplish all except… A. Reduce clerical costs B. Reduce lost work days C. Reduce damaged product D. Reduce raw material prices 23. The three components needed to create a fire are… A. Heat, fuel, confined space B. Oxygen, heat, fuel C. Fuel, friction, oxygen D. Sparks, heat, oxygen 24. Which indicate that a HAZMAT container should not be moved? A. A label identifying the HAZMAT type B. A damaged or leaking container C. Location in a confined space D. Proximity to other HAZMATs 25. “OSHA” is the acronym for? A. Occupational Safety & Health Analysis B. Occupational Shipbuilding Health Association C. Occupational Safety & Health Administration D. Occupational Slip Hazard Analysis Quality 1. Which is not part of the PDCA cycle? A. Plan B. Do C. Check D. Analyze 2.The acronym “SPC” stands for… A. Special Process Control B. Statistical Process Control C. Stylized Part Continuity D. System Process Chart 3. The following chart is used to determine upper and lower control limits… A. Histograms B. Control charts C. Run charts D. Benchmarks 4. Which is the most useful tool for root cause failure analysis? A. Run charts B. Control charts C. Pareto diagrams D. Fishbone Ishikawa diagrams 5. Which factor is the most critical for quality production? A. Proper equipment maintenance B. Proper documentation C. Proper training D. Proper auditing 6. The precision of the inspection process must be… A. Less than that of the manufacturing process B. Greater than that of the manufacturing process C. Equal to that of the manufacturing process D. It is not important, as long as inspection is done 7. An operator notices an unexplained flaw in production. He should… A. correct the flaw by adjusting his machine B. Wait for the flaw to disappear C. Inform a supervisor D. Assume there is a bad batch of raw material 8. Which is NOT part of a good quality system? A. Preventive action B. Auditing C. Inspection D. Undocumented improvements 9. Which is NOT a basis of the ISO 9000 quality standards? A. Leadership B. Customer focus C. Factual approach to decision making D. Competitive advantage 10. A quality system is effective if… A. All employees take responsibility for it B. If senior management accept it C. If production floor workers accept it D. The customer sees it as necessary 11. A company is interested in improving its quality. The best approach would be… A. Increase training for safety B. Incorporate quality into the production process C. Increase inspection of the finished product D. Hire more inspectors and auditors 12. A Quality product is defined by… A. The product is not scrapped B. The product is within tolerance C. The product meets or exceeds the expectations of the customer D. The product is made within cost and schedule 13. Which of the following is NOT true for a nonconforming critical single point failure product? A. The product should be tagged as nonconforming B. The product should be isolated from other product C. The product should be placed into service as soon as possible D. The product should be evaluated by trained personnel only 14. A company has 12 defects in 1000 products produced. What is the percentage of defects? A. 0.012% B. 1.2% C. 12% D. 998% 15. Which of the following is NOT an objective of a quality audit? A. To determine whether the quality system meets its objectives B. Verify that the quality system continues to meet customer requirements C. To assure that products are safe D. To determine quality standards 16. According to continuous improvement techniques, what number of defects is an acceptable goal? A. 150 per million B. 5.6 per million C. 3.4 per million D. None 17. The Japanese term poka yoke refers to… A. Continuous improvement B. Zero defects C. Nonconforming product D. Mistake proofing 18. The following are all factors to be considered for an inspection sampling plan except… A. Cost of inspection B. Governmental quality system regulations C. Previous quality history D. Process capability 19. Non-conforming product must be… A. Reworked so that it can be sold B. Scrapped because it does not meet specifications C. Analyzed to determine why it does not meet specifications D. Sold at a discount 20. Which document determines how a product is processed? A. SOP B. Audit report C. MRB report D. Control chart 21. Corrective actions to a manufacturing process… A. Should be communicated to the operator on the next shift B. Should be implemented by the operator as soon as possible C. Should be only implemented after an audit D. Should be documented and incorporated into SOPs 22. The quality of a product is defined… A. After the product is produced B. During the design phase C. After any problems are found D. While working with customers to develop the product 23. Which is NOT an approach of total quality management? A. Involvement from all employees, not just management B. Designing quality into the product C. Tracking quality and results D. Informing the customer about quality products 24. Six Sigma quality is achieved when under ________ per million defects are produced. A. 3.4 B. 15 C. 300 D. 1600 25. Which of the following is the lowest overall cost? A. Waiting for customer complaints B. Reworking nonconforming products C. Fixing production process defects as they are found D. Implementing a quality control program Maintenance 1. “VFD” stands for A. Variable Function Discharge B. Velocity Field Dump C. Variable Frequency Drive D. Variable Field Diode 2. Which method of shaft attachment is capable transmitting the highest torque? A. Pin B. Square key C. Taper lock bushing D. Setscrew 3. Multiple E-stop controls for a single machine are typically… A. Wired independently B. Wired in series C. Wired in parallel D. Double insulated 4. What is the minimum oxygen concentration requirement by volume for a confined space? A. 5.6% B. 12.4% C. 19.5% D. 78.8% 5. Care must be taken in working with soluble oil mixtures due to… A. Its high reactivity B. Its capability to burn C. Its sensitivity to contamination D. Its ability to harbor bacteria 6. Which is NOT a component of a lockout/tagout procedure? A. Apply the lockout/tagout devices to the energy-isolating devices B. Notify affected workers lockout/tagout is about to occur C. Request an operator to monitor that the controls are not used D. Shut down the machine or equipment 7. Spalling of bearing surfaces refers to… A. The melting failure of the bearing B. The discoloration of the bearing C. The cracking failure of the bearing D. The flaking off of metal of the bearing 8. An out of balance shaft condition increases in severity with… A. Increasing RPM B. Increasing the number of starts and stops C. The greater the overall size of the assembly D. The greater the size of the shaft 9. The primary purpose of an interlock is… A. To automate different parts of the process together B. To prevent operators from engaging the wrong equipment C. To lock operators out of sensitive components D. To lock equipment systems from movement 10. Dust-air separators use _______ to remove dust. A. Magnetic force B. Electrical force C. Centrifugal force D. Gravitational force 11. Hydraulics and pneumatic systems are different in that… A. Hydraulics tend to use lower pressures B. Hydraulics will leak C. Pneumatics must be vented D. Air is compressible 12. The safety color orange is used to identify… A. Fire equipment, exit signs, panic buttons B. Hazardous equipment or parts of a machine C. Tripping or falling hazards D. Safety signs 13. Which maintenance program has the highest cost? A. Predictive maintenance B. Preventive maintenance C. Reactive maintenance D. Total productive maintenance 14. Which maintenance program is based on sensing changes in equipment performance? A. Predictive maintenance B. Preventive maintenance C. Reactive maintenance D. Total productive maintenance 15. The primary purpose ball bearings are used over plain bearings is… A. Higher loadings B. Higher speeds C. Less maintenance D. Lower friction 16. The primary purpose of lubricant in bearings is… A. To prevent/minimize metal to metal contact B. To keep the bearing cool C. To allow the bearings to slide D. To eliminate corrosion 17. The HAZ or Heat Affected Zone from welding refers to… A. The area of material that is distorted B. The portion of parent material that was melted C. The portion of material that was added D. The parent material whose properties may be altered 18. Dwelling a cutting tool in stainless steel should be avoided because… A. It creates excessive heat B. It dulls the cutter C. It work hardens the material D. The tool will cut oversize 19. Step drilling is a technique used to… A. Accurately drill holes B. Create counterbored holes C. Prevent drilling too deep D. Transfer hole locations 20. Spiral point taps differ from hand taps because… A. They direct the chip before them B. They can’t thread to the bottom of the hole C. They require more force D. They require a different tap drill hole size 21. The dimension of an external thread taken from root to root is the _______ diameter. A. Major B. Pitch C. Minor D. Nominal 22. Solenoids are often used to control _______ flow. A. Electrical B. Data C. Light D. Fluid 23. Capacitors must be treated with care because… A. They are easily damaged B. They can store charges for long periods of time C. They can leak fluid if tipped D. They are often not marked well 24. A electrical resistor is analogous to which of the following hydraulic examples? A. A reservoir B. A diaphragm blocking flow C. A driven propeller D. A reduction in pipe section 25. Torch cutting stainless steel is not possible because… A. It has too high melt temperature B. It will damage the material C. The cutting torch will get clogged D. The material does not readily oxidize