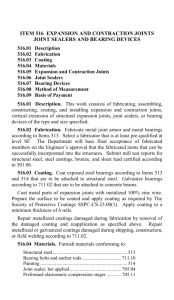

introduction

advertisement

Bearing It is the interface between two major components of bridge structure i.e. super structure and sub structure. The factors causing movement in the bridge superstructure Thermal expansion and contraction deformation under live load Longitudinal forces- tractive / breaking Wind loads Settlement of supports Seismic forces Creep and shrinkage of concrete Functions of bearing: Load transmission Permit rotary or rocking movement caused by deflection of super structure. Allow horizontal movement of super structure due to expansion or contraction. Restrict lateral movement of super structure Translation can be permitted by the following modes of action : – – – – By sliding action By rolling action By shearing strain By racker and pinion devices (as in gears) Rotation can be permitted by the following modes – By rocking/hinge action – By differential compression (as in elastomeric pads) – By bending/flexure (as in tall piers, portals). Classification Based on Degree of Freedom 1. 3. Fixed Sliding Rocker and roller Based on material used 1. Steel Bronze Synthetic material 2. 2. 3. • • Elastomeric pads PTFE-Poly Tetra Fluoro Ethylene SELECTION OF BEARINGS The selection depends upon a no. of factors Functional requirement Expected life –compatible with life of bridge Maintenance efforts- should be minimum Cost Other factors – Height of the bearing – Management of horizontal force transferred to the substructure – Performance under seismic loads. Even when bearing has been selected Choose the large components Specify the highest grade of material Insist upon strictest tolerance possible i.e First cost shouldn’t be the criteria SLIDING BEARINGS DIFF. SLIDING BEARINGS a) b) Common materials being used and their co-efficient of friction are Material Mild steel over mild steel 0.2 to 0.3 Mild steel over phosphor bronze c) PTFE over stainless steel 0.15 Less than 0.08 PTFE It is a Linear chain polymer of high molecular strength Chemically inert Low coeff. of friction Not oxidized easily Remains stable at extreme atmospheric temperatures Resistant to all common solvent. MAINTENANCE – GREASING Equipments required for greasing of sliding bearings : Jacks (50 ton capacity) 2 nos Hard wooden packing (below and above jack) Grease graphite grade 3 conforming to IS 508 Kerosene or released black oil for cleaning 6 mm thick steel scrapers Mortar pan Cotton waste. DESIGN ASPECTS As per clause 3.16 of IRS : Steel Bridge Code the allowable bearing pressure for different materials is as under : – Stone Masonry = 36 kg/sqcm – PCC (1:2:4) = 31.6 kg/sqcm – RCC = 0.2 * fck (average pressure) = 0.3 * fck (local max. pressure) ROLLER BEARING ELASTOMERIC BEARING ELASTOMERIC BEARINGS The elastomeric bearings offer a number of advantages as listed below: 1. 2. 3. 4. 5. Minimum maintenance- as no moving parts Installation is easy Permits movement in all directions Occupies small space Serves as a shock absorber due to anti-vibrations properties of elastomer 6. As an aid to better management of longitudinal forces. IMPORTANT FINDINGS by ORE (office for research & experiments) of FRENCH Elastomer doesn’t follow hook’s law & E ≠constant But G = Constant & G is more relevant than E µ between elastomer & base material unaffected by nature of contact surface µ reduces with increased normal loads(N) µ=0.1+0.6/N IMPORTANT FINDINGS by ORE contd. Performance of elastomer not affected by temp variation with in range of (-15 to +50oC) Under cyclic load, it becomes flexible Repetitive vertical loading more detrimental than repetitive shear loading Tendency to slip, when normal pressure is less than 2MPa. PROPERTIES OF ELASTOMER Property Unit Test method I.S. Specification reference Value specified 1. Physical Properties : 1.1 Hardness* 1.2 Mini. tensile strength 1.3 Mini. elongation at break 2.0 Max comp. set 3 Accelerated ageing IRHD IS:3400 (Part II) 60 + 5 MPa IS:3400(Part I) 17 % % % IS:3400 (Part I) IS:3400 (PartX) duration 24hr +0, -2 temp 100 + 1 oC 400 35 IS:3400 (Part IV) duration 70 h temp 100 + 1 oC 3.1 Maximum change in hardness IRHD + 15 3.2 Maximum change in tensile strength 3.3 Maximum change in elongation % -15 % -30 DIMENSIONAL TOLERANCES SN 1. 2. 3. 4. ITEMS Overall plan dimensions Total bearing thickness -0, +6 mm -0, +5% Parallelism A. Of top surface of bearing with respect to the bottom surface as datum B. Of one side surface with respect to the other as datum 1 in 200 1 in 100 A. B. 5. TOLERANCES A. B. C. Thickness of individual internal layer of elastomer Thickness of individual outer layer Plan dimensions of laminates Thickness of laminate Parallelism of laminate with respect to + 20% (max. of 2 mm -0, + 1 mm -3 mm, +0 + 10 % 1 in 100 DESIGN ASPECTS OF ELASTOMERIC BEARINGS Dimensional check – – – – – – L0 ≤ 2b0 b0/10 ≤ H ≤ b0/5 Shape factor = 6 to 12 For no slip condition min = 2 Mpa max = 10 Mpa = 0.1 + 0.6/ m DESIGN ASPECTS contd. Distortion limit = 70% of total elastomer ht Bed block bearing stress ≤ 0.25 x fck For no uplift & condition ei under DL tanα dead b/6 under LL ei b/6 tanα dead 1.5 tan live DESIGN ASPECTS contd. Shear stress due to Comp load + horizontal load + rotation < 5 G Due to comp load = 1.5/S [(Pc + 1.5 Ps)/ l x b] Due to Horizontal = H /l x b Due to rotation = Gb2/2hi x H (tan c + 1.5 tan s) DESIGN ASPECTS contd. Thickness of steel plate 2(hi + hi+1) (Pc + 1.5 Ps) hs > ------------------------------l x b x s hi , hi+1 = thickness of elastomer layers on both sides of steel plate. INSPECTION AND QC CERTIFICATE The bearings should be accompanied by an authenticated coy of the test certificate with folowing information : – Name of Manufacturer – Date of manufacture – Grade of elastomer – Bearing Dimensions – Production Batch no. – Acceptance lot no. – Date of testing – Specific bridge location – Explanation of markings on the bearing. PERIODICAL INSPECTION AND MAINTENANCE The inspecting official should look for the following aspects : – – – – – – – – Correct position Excessive shear (movement) Excessive bulging Separation of rubber from steel lamination plate Cracking/tearing of Elastomer Flattening out Off loading of one edge (Excessive rotation ) Clean surroundings Anti slip devices Suitability of Bearing for spans Type of bearing Bridge & Spans (mt) Remarks Both end steel plates. Plate girders 9.15, 12.2, 18.3, 24.4, 30.5 Elastomeric and PTFE on trial basis phosphor bronze Composite 9.15, 12.2, For U/S O/W - 30.5 18.3, 24.4, 30.5 (With one end fixed) Rocker & Roller O/W through girders30.5, 45.7(2 rollers), 61.0, 76.2 (4 rollers) Rocker & Roller O/W through girders with oil bath more than 76.2 One end fixed & other free -do- Load range & movement in Bearing Type of bearing Load (T) Steel sliding plates. 20-133 Movement (mm) one way 25 Roller bearing 60-266 100 Elastomeric Bearing 30-220 60 Pot bearing 20-1780 No limit POT BEARING PTFE It is a Linear chain polymer of high molecular strength Chemically inert Low coeff. of friction Not oxidized easily Remains stable at extreme atmospheric temperatures Resistant to all common solvent. WHY POT BEARINGS ? Ordinary elastomeric bearing can’t be used as a fixed bearing Translation allowed by elastomeric bearing is restricted by its thickness – 0.5 to 0.6 of thickness Thick elastomeric pads are rather unstable Limit of vertical load which can be placed safely on elastomeric pads – It causes excessive compression & bulging. POT BEARINGS Pot bearing – It take beneficial properties of elastomer in fixed bearings & design of large expansion bearings Rotational movement permitted by shear deformation of an elastomeric pad Translational movement restraint by completely encasing the elastomeric pad in a POT No comp. deflection of elastomer as it is encased Sliding component can be added at top. THANKS