Process Engineer - sona blw precision forge, inc.

advertisement

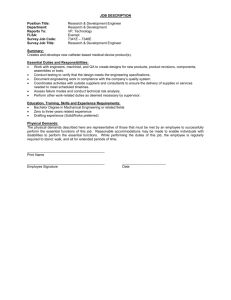

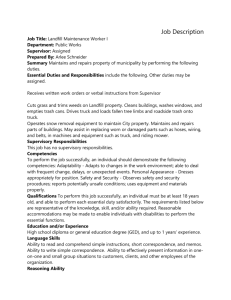

SONA BLW PRECISION FORGE, INC. Engineering Department Job Description JOB TITLE Process Engineer SUMMARY Design, troubleshoot and revise plans required for single and progressive stage forging and extrusion processes by performing the following duties. ESSENTIAL DUTIES AND RESPONSIBILITIES include the following. Other duties may be assigned. ______ Develops models and draft files and drawings of dies, electrodes and related components required to form complete forging and coining of parts. _____ Determines sequence, number and design of die stages in which single or progressive forming, forging, coining, trimming or piercing will be accomplished and type of die sets required to produce complete part, based on knowledge of dies, forming processes and machines. _____ Develops necessary process prints for all sequences in the manufacturing process including dimensional requirements for progressive manufacturing stages. _____ Observes setup and tryout of newly developed tooling in production machine to determine need for redesign or readiness for production use. _____ Updates necessary model and drawing files and documentation according to procedures. _____ Provides support and guidance for continual improvement projects. Also to include departmental duties and responsibilities: Design tooling for, & work with: Maintenance. Die Shop. CNC department. Quality Assurance. Trouble-shoot Manufacturing Problems. Produce all Tooling Drawings and models Revision of all Tooling Drawings. Drawing Control. Blueprint Issuance. Created on 03-03-2003 Develop Packaging Instructions. Develop Control Plans. Develop FMEA's. Develop Process Flow Documents. Develop New Routers. Revise Routers. Revise Manufacturing Orders. Make New & Revise Parts Lists. Maintain Logs of all Eng. Documents. Develop Eng. Change Notices. Attend daily Parts & Dies Review. Attend daily forge Mtgs. .Attend scrap reduction scrap meetings Attend New Parts Mtgs. Attend daily MRB meetings. QUALIFICATION REQUIREMENTS To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. Working knowledge of machining and forging equipment and processes including mills, lathes, EDM, CNC turning and milling centers, grinders, hammers and presses. EDUCATION AND/OR EXPERIENCE Bachelor’s Degree (B.A.) from a four year college or university; or five to seven years related experience and/or training; or equivalent combination of education and experience. LANGUAGE SKILLS Ability to read, analyze and interpret general business periodicals, professional journals, technical procedures or governmental regulations. Ability to write reports, business correspondence and procedure manuals. Ability to effectively present information and respond to questions from groups of managers, clients, customer and the general public. MATHEMATICAL SKILLS Ability to work with mathematical concepts such as probability and statistical inference, and fundamentals of plane and solid geometry and trigonometry. Ability to apply concepts such as fractions, percentages, ratios and proportions to practical situations. REASONING ABILITY Ability to solve practical problems and deal with a variety of concrete variables in situations where only limited standardization exists. Ability to interpret a variety of instructions furnished in written, oral, diagram or schedule form. Created on 03-03-2003 PHYSICAL DEMANDS The physical demands described here are representative of those that must be met by an employee to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. While performing the duties of this job, the employee is frequently required to stand, talk and hear. The employee is occasionally required to walk; sit; use hands to finger, handle or feel objects, tools or controls; reach with hands and arms; climb or balance; stoop kneel crouch or crawl. Specific vision abilities required by this job include close vision, distance vision, peripheral vision, depth perception and the ability to adjust focus. WORK ENVIRONMENT The work environment characteristics described here are representative of those an employee encounters while performing the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. While performing the duties of this job, the employee is frequently exposed to extreme heat. The employee occasionally works near moving mechanical parts; in high, precarious places; and in outside weather conditions and is occasionally exposed to wet and/or humid conditions, fumes or airborne particles, toxic or caustic chemical, extreme cold and vibration. The noise level in the work environment is usually loud. ENVIROMENTAL MANAGEMENT RESPONSIBILITIES _____ Understand and comply with all the SONA BLW ISO 14001 Environmental Management System’s procedures and work instructions _____ Understand and comply with all the SONA BLW TS 16949 Management System’s procedures and work instructions _________________________________________________ Employee Signature: _________________________________________________ Supervisor Signature: _________________________________________________ Date: Created on 03-03-2003