swapnil s suryawanshi

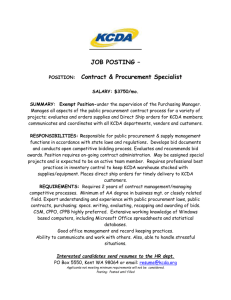

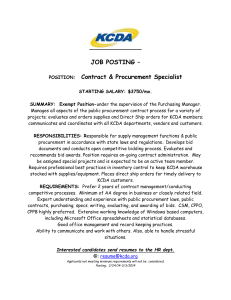

advertisement

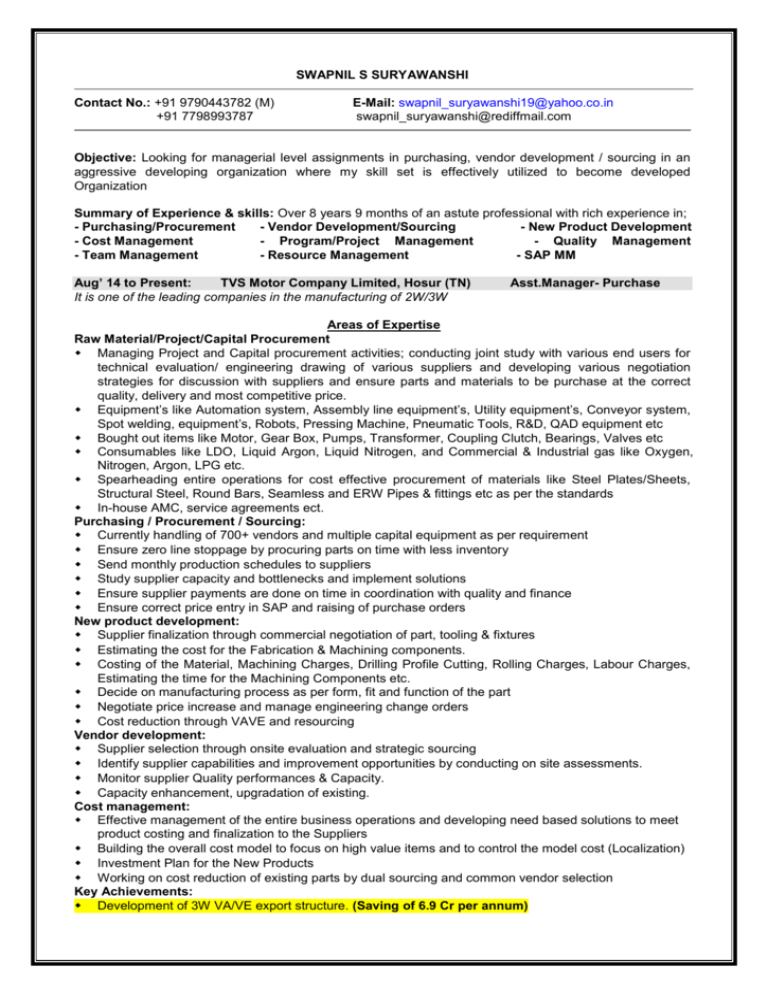

SWAPNIL S SURYAWANSHI Contact No.: +91 9790443782 (M) +91 7798993787 E-Mail: swapnil_suryawanshi19@yahoo.co.in swapnil_suryawanshi@rediffmail.com Objective: Looking for managerial level assignments in purchasing, vendor development / sourcing in an aggressive developing organization where my skill set is effectively utilized to become developed Organization Summary of Experience & skills: Over 8 years 9 months of an astute professional with rich experience in; - Purchasing/Procurement - Vendor Development/Sourcing - New Product Development - Cost Management - Program/Project Management - Quality Management - Team Management - Resource Management - SAP MM Aug’ 14 to Present: TVS Motor Company Limited, Hosur (TN) It is one of the leading companies in the manufacturing of 2W/3W Asst.Manager- Purchase Areas of Expertise Raw Material/Project/Capital Procurement Managing Project and Capital procurement activities; conducting joint study with various end users for technical evaluation/ engineering drawing of various suppliers and developing various negotiation strategies for discussion with suppliers and ensure parts and materials to be purchase at the correct quality, delivery and most competitive price. Equipment’s like Automation system, Assembly line equipment’s, Utility equipment’s, Conveyor system, Spot welding, equipment’s, Robots, Pressing Machine, Pneumatic Tools, R&D, QAD equipment etc Bought out items like Motor, Gear Box, Pumps, Transformer, Coupling Clutch, Bearings, Valves etc Consumables like LDO, Liquid Argon, Liquid Nitrogen, and Commercial & Industrial gas like Oxygen, Nitrogen, Argon, LPG etc. Spearheading entire operations for cost effective procurement of materials like Steel Plates/Sheets, Structural Steel, Round Bars, Seamless and ERW Pipes & fittings etc as per the standards In-house AMC, service agreements ect. Purchasing / Procurement / Sourcing: Currently handling of 700+ vendors and multiple capital equipment as per requirement Ensure zero line stoppage by procuring parts on time with less inventory Send monthly production schedules to suppliers Study supplier capacity and bottlenecks and implement solutions Ensure supplier payments are done on time in coordination with quality and finance Ensure correct price entry in SAP and raising of purchase orders New product development: Supplier finalization through commercial negotiation of part, tooling & fixtures Estimating the cost for the Fabrication & Machining components. Costing of the Material, Machining Charges, Drilling Profile Cutting, Rolling Charges, Labour Charges, Estimating the time for the Machining Components etc. Decide on manufacturing process as per form, fit and function of the part Negotiate price increase and manage engineering change orders Cost reduction through VAVE and resourcing Vendor development: Supplier selection through onsite evaluation and strategic sourcing Identify supplier capabilities and improvement opportunities by conducting on site assessments. Monitor supplier Quality performances & Capacity. Capacity enhancement, upgradation of existing. Cost management: Effective management of the entire business operations and developing need based solutions to meet product costing and finalization to the Suppliers Building the overall cost model to focus on high value items and to control the model cost (Localization) Investment Plan for the New Products Working on cost reduction of existing parts by dual sourcing and common vendor selection Key Achievements: Development of 3W VA/VE export structure. (Saving of 6.9 Cr per annum) Development of packaging solutions like Returnable stillage over the existing packing (Saving of 1.2 Cr per annum) Working on special projects for continuous improvement in purchasing methods like Supplier consolidation, Single window procurement with better price, Volume discount, Price list settlement to cut down external spend. Jan’ 11 to Jul’ 14: Kalyani Carpenter Special Steel Limite Pune Asst.Manager- Purchase It is one of the leading companies in the manufacturing of Speciality & High Alloy steel including Electro Slag Re-melter (ESR) quality. Areas of Expertise Project Procurement Nov -2012 to Jul - 2014 Project related procurement for our Group company M/s Baramati Speciality Steels Limiter, Satara. Rolling mill & its spares procurement, Annealing, Hardening Furnace, Tempering Furnace, Transformer, SG Iron Roll, Lab equipment’s like microscopes, Abrasive cutting machine, Double disk polishing machine, UTM machine etc, Band saw machine, Overhead cranes, Oil & Lubricants, Transfer trolley, Compressors, Power pack, Motors, Gearbox etc. Purchase / Inventory Management Managing purchase activities; conducting joint study with various end users for technical evaluation of various suppliers and developing various negotiation strategies for discussion with suppliers. Spearheading entire operations for cost effective procurement of materials like Steel Plates/Sheets, Structural Steel, Round Bars, Seamless and ERW Pipes & fittings etc as per the standards. Subcontracting of Fabrication components Like VOD, LF, Casings, Base frames, Conveyor Fabrications, induction hardening, flame hardening, machining of different component Estimating the cost for the Fabrication & Machining components. Costing of the Material, Machining Charges, Drilling Profile Cutting, Rolling Charges, Labour Charges, Estimating the time for the Machining Components etc. Consumables like LDO, Liquid Oxygen, Liquid Argon, Liquid Nitrogen, and Commercial & Industrial gas like Oxygen, Nitrogen, Argon, Acetylene, LPG etc. Streamlining the system and procedures for effective inventory control for ensuring ready availability of materials to meet the production targets. Ensuring optimum inventory levels for achieving cost savings without hampering the project process and preparing reports for the same. Ensuring timely release of PO’s & work orders updating Formulating the budgets for timely procurement of raw material and cost analysis to ensure the smooth execution of projects. Capital/Asset procurement. In-house AMC, service agreements/contracts ect. Vendor Development Identifying and developing vendors for all brought items and raw material. Developing partnerships with local & foreign suppliers; managing cost, delivery and quality norms. Consistently evaluating vendor performance to ensure adherence to predefined specifications and supply of quality material / execution of job works. Assessing performance of the vendors based on various criterions such as percentage of rejections, quality, timely delivery, price, packing, etc. Issuing delivery schedules to suppliers (Current month and tentative plan for next month). Aug’ 10 to Dec’ 10: Uttam Galva Metallics Limited, Wardha Senior Engineer- Purchase It is one of the leading companies in the manufacturing of Pig Iron for the Steel plant. Uttam Galva is having four major plants like Blast Furnace, Coke Oven, Sinter Plant & Power Plant. Areas of Expertise Purchase / Inventory Management Managing purchase activities; conducting joint study with various end users for technical evaluation of various suppliers and developing various negotiation strategies for discussion with suppliers. Spearheading entire operations for cost effective procurement of materials like Steel Plates/Sheets, Structural Steel, Round Bars, Seamless and ERW Pipes etc as per the standards. Subcontracting of material like Shafts, Guide Roller, Idler rollers, Geared Shaft, Head & Tail Pulley etc. Consumables like Oxygen, Nitrogen, Hydrochloric acid, LPG commercial and industrial gas etc. Streamlining the system and procedures for effective inventory control for ensuring ready availability of materials to meet the production targets. Ensuring optimum inventory levels for achieving cost savings without hampering the project process and preparing reports for the same. Subcontracting material for induction hardening, flame hardening and machining of different component. Ensuring inspection of raw material and work orders, updating & timely release of PO’s. Formulating the budgets for timely procurement of raw material and cost analysis to ensure the smooth execution of projects. Feb’ 07 to Apr’ 10: Mahindra Engineering and Chemical Products Limited,Pune Engineer (Engineering Division) It is ISO 9001:2000 company, subsidiary of Mahindra & Mahindra Group and one of the leading company in the manufacturing of Material Handling Equipments mainly chain conveyors e.g. Bucket Elevators, Flow Conveyors, Drag Chain Conveyors, Apron Feeders, Air Slides, Belt & Screw Conveyors, Unit material handling like Car handling in Paint Shop, etc. Areas of Expertise Quality, Inventory Management & Sourcing Managing Purchase Quality inspection activities; conducting joint study with various end users for technical evaluation of various suppliers and developing various negotiation strategies for discussion with suppliers. Vendor development activity. Spearheading entire operations for cost effective procurement of raw materials like Steel Plates/Sheets, Structural Steel, Round Bars, and Forged Chain- Link and brought items like Sprockets, Roller, and Tail Wheel. Finalizing the specifications of materials and establishing quality & quantity limits for effective inventory control and reducing wastages. Streamlining the system and procedures for effective inventory control for ensuring ready availability of materials to meet the production targets. Ensuring optimum inventory levels for achieving cost savings without hampering the project process and preparing reports for the same. Subcontracting material for induction hardening, flame hardening and machining of different component. Ensuring inspection of raw material and work orders, updating & timely release of PO’s. Formulating the budgets for timely procurement of quality raw material and cost analysis to ensure the smooth execution of projects. ACADEMIA 2006 Bachelor of Mechanical Engineering from Shri Sant Gajanan Maharaj College of Engineering, Shegaon, Affiliated to Amravati University. Secured 67.85% ACADEMIC PROEJCTS EXECXUTED Title : “Heat Transfer in a Model House of Gadhi Soil and its C.F.D Analysis” SEMINARS AND INDUSTRIAL TRAININGS ATTENDED Attended a o Seminar on “Unmanned Aerial Vehicle”. o Industrial Training at “Padsons Pvt Ltd, Akola”. PERSONAL DOSSIER Date of Birth Linguistic Abilities Permanent Address Present Address Phone No Passport NO Issue & Expiry date Notice Period : : : : : : : : 11th November 1983 English, Marathi and Hindi Pune (M.S.) Hosur (TN) +91 9790443782 or 7798993787 G6767877 18/01/2008 to 17/01/2018 3 month (negotiable)