NI RF Hardware Overview - The University of Texas at Austin

advertisement

National Instruments MIMO/OFDM Prototype

Hardware Description

May 25, 2004

By

Amit Gupta

Antonio Forenza

Robert W. Heath, Jr.

Wireless Networking and Communications Group (WNCG)

Department of Electrical and Computer Engineering

The University of Texas at Austin

1 University Station C0803

Austin, TX 78712-0240 USA

Phone: +1-512-425-1305

Fax: +1-512-471-6512

{amitg, forenza, rheath}@ece.utexas.edu}

Table of Contents

1

HARDWARE OVERVIEW ................................................................................................................ 3

1.1

1.2

2

DESCRIPTION OF THE PXI CHASSIS .......................................................................................... 4

2.1

2.2

2.3

2.4

2.5

3

Transmitter ................................................................................................................................... 5

Receiver ........................................................................................................................................ 5

Device Drivers .............................................................................................................................. 6

Clock Synchronization ................................................................................................................. 6

Data Synchronization ................................................................................................................... 6

HARDWARE LIMITATIONS ........................................................................................................... 7

3.1

3.2

4

PXI Chassis .................................................................................................................................. 3

DC Power Supply ......................................................................................................................... 4

Phase Offset.................................................................................................................................. 7

Not a Real-time System ................................................................................................................ 7

LIST OF ADDITIONAL PARTS FOR THE NI HARDWARE ...................................................... 7

4.1

4.2

Parts Purchased............................................................................................................................. 7

Planned Purchases ........................................................................................................................ 8

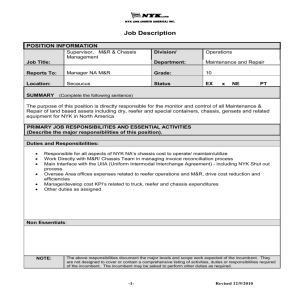

1 Hardware Overview

The framework of the NI software/hardware used to implement the MIMO/OFDM

system prototype is depicted in Figure 1. The hardware consists essentially of three

devices: two PXI chassis and the DC power supply. Hereafter we provide brief

description of these devices.

Digital

LabVIEW VI

Receive

Antenna

NI PXI-5421

Arbitrary

Waveform

Generator

(100 million

samples per

second)

NI PXI-5600

Down-Converter

Carrier

Frequency

250 kHz – 2.7

GHz

Figure 1

Analog

Analog

NI PXI-5610

Up-Converter

Carrier Frequency

250 kHz – 2.7GHz

NI PXI-5620

High Speed

Digitizer

(64 million

samples per

second)

Digital

Transmit

Antenna

LabVIEW VI

NI software/hardware framework

1.1 PXI Chassis

In Figure 2 is a picture of the hardware. The hardware is housed in two18-slot PXI

chassis. The two transmit units and the two receive units are placed in separate PXI

chassis. Each chassis is connected to a PC through a fiber optic cable which connects the

chassis’ MXI-3 card to a PCI card in the PC. The MXI-3 card allows the components in

the chassis to be connected directly to the PCI bus of the PC; therefore, the PXI chassis

must be turned on before the PCs are booted so that the PCs will correctly recognize the

PXI hardware at boot up. More details on the transmit/receive PXI chassis are provided

in the next section.

DC Power

Supply

For Amps

Transmitter

Chassis

Receiver

Chassis

Figure 2

Picture of NI hardware

1.2 DC Power Supply

We found that using low-noise amplifiers (LNA) at the receiver end of the system was

the only way to provide us with a signal which was strong enough to be correctly

decoded at the receiver. The amplifiers that we used were Minicircuits ZQL2700MLNW amplifiers. On each of the receiver units before the signal reached the

digitizer we employed a LNA. The LNAs need to be supplied 15 volts of DC power—

which is why we have a DC power supply.

2 Description of the PXI Chassis

In Figure 3 is a picture of the PXI chassis. One slot is used to link the NI hardware to the

software (LabVIEW). Moreover, three slots are employed for the transmitter unit and

four for the receiver unit. Note, in Figure 3 transmit and receive slots are located in the

same chassis only for demonstration purposes. However, in the latest version of the

prototype one chassis contains the transmit units and the other one the receive units, as

mentioned before.

Link to Computer

Receiver

Down-converter

Figure 3

Transmitter

ADC

DAC

Up-converter

Picture of the PXI chassis

2.1 Transmitter

The transmit unit consists of two parts – an upconverter (PXI 5610) and an arbitrary

waveform generator (PXI-5421.) When used together the unit is called the PXI-5670

Signal Generator. The arbitrary waveform generator (ARB) runs at a maximum sampling

rate of 100 MSamples/s. When used in conjunction with the upconverter, the ARB takes

the discrete I-Q waveform created in LabVIEW and then creates a continuous waveform

at an IF of 25MHz which it sends to the upconverter. The upconverter then creates and

transmits the desired RF signal. The upconverter can transmit on a maximum frequency

of 2.7 GHz.

2.2 Receiver

The receiver also consists of two units. The first component is the downconverter (PXI5600) and the second is the high speed digitizer (PXI-5620.) The downconverter also has

a maximum frequency of 2.7 GHz and it downconverts the received signal to an IF of 15

MHz. It can receive a maximum bandwidth of 20 MHz. The digitizer operates at a

maximum sampling frequency of 64MSamples/s. The digitizer is equipped with a digital

downconverter chip (DDC) that can carry out digital downconversion from IF when the

bandwidth of the signal is less than1.25Mhz. Otherwise if the bandwidth of the signal is

greater than 1.25 MHz then the downconversion occurs in software, which is

considerably slower.

2.3 Device Drivers

The transmit and receive units both consists of two pieces of hardware. There are two

different ways of programming each unit. With the receiver, you can use the RF Signal

Analyzer (RFSA) drivers to program the downconverter and digitizer together as a single

entity or you can use the NI-Tuner drivers to program the downconverter and the NIScope drivers to program the Digitizer. When first using the hardware it is generally a

better idea to begin by using the RFSA drivers since they are simple to use. As a tradeoff

though, the ease of use comes at the cost of flexibility and robustness. Many of the

systems parameters are automatically controlled by the drivers and as a result full control

of all the hardware’s parameters is lost.

Using the two separate drivers gives the user much of that control back and parameters

such as the sampling rate and IF frequency can now be changed. However, of course, the

classic tradeoff is incurred as the hardware is a little more difficult to program. So far for

my applications I have stuck to using the combined RFSA driver set. For the transmitter

a similar driver breakdown applies. For the combined unit the RF Signal Generator

drivers (RFSG) are used. Individually the ARB uses the NI-FGEN driver while the

upconverter can be programmed using the same RFSG drivers as the combined unit.

2.4 Clock Synchronization

A 10 MHz reference clock is used to synchronize the upconverter/ARB at the transmitter

sided to the downconverter/Digitizer at the receiver side. A connection on the front of

the hardware devices synchronizes those components together. In order to carry out

carrier synchronization, the clocks on the transmit unit and the receive units can also be

synchronized together through two basic different configurations. The first is through the

backplane of the PXI chassis—this of course only works of both the transmitter and

receiver are in the same PXI chassis. The unit which is in slot 2 of the PXI chassis can be

set to synchronize the 10 MHz reference clock which the chassis comes equipped with

(actually, ONLY the unit in slot 2 of the PXI chassis can set the chassis reference clock).

Usually it makes most sense to have the receive unit in slot 2 of the chassis and to

synchronize according to the receivers clock. The transmit unit can then synchronize

according to the PXI chassis reference clock.

The other setup is to use the external connections to synchronize the carrier frequencies

of the transmitter and receiver. Connecting the 10 MHz clock out on the downconverter

to the clock reference in input of the upconverter will also allow for similar

synchronization. NI documentation tells us that this type of synchronization is more

accurate the PXI backplane synchronization.

2.5 Data Synchronization

In order to carry out timing synchronization, a digital trigger is sent from transmitter to

receiver to signify when signal transmission has begun. A trigger is sent externally using

the PF1 connection on both the Digitizer and the ARB. You cannot send a trigger using

the PXI backplane because the backplane is not connected all the way along all of the

slots. The vertical bars on the front of the case in between the slot numbers demarcate

the various PXI connections. The clock reference is one of the few signals which are

available to all slots, but the trigger lines are not.

The operation of the data synchronization is also controlled in the software. There is a

reference position input to the “niScope configure horizontal timing.VI” at the receiver

which determines how the trigger operates. The input should be a decimal between 0 and

1 and it refers to the percentage of data which is acquired pre-trigger versus the

percentage of data which is acquired post-trigger. Theoretically for the trigger to work as

expected, the value should be set to 0 so that no pre-trigger data is acquired and that all

data is post-trigger data. In reality, this does not happen. When the reference position is

set to 0, some of the data is lost pre-trigger. Therefore it should be set to a very small

value greater than 0 (we use 8.2x10^-6.) Depending on your application the only way to

set this correctly is by trial and error.

3 Hardware Limitations

3.1 Phase Offset

When synchronizing the clocks of the transmitter and the receiver, the clock’s frequency

will be locked, however the phase will not be. As a result there will be a constant phase

shift between the transmitter and receiver. This phase shift will be random, but it will be

constant for the whole acquisition period. For the OFDM application, this phase offset

was not a problem as it is accounted for through channel estimation.

3.2 Not a Real-time System

One of the largest limitations of the current system is that it is not a real-time system.

Data can only be acquired in chunks and not through a continuous acquisition. This is

because the digitizer is not able to downconvert the signal from IF to baseband in

hardware but instead does it through software. This downconversion is computationally

intensive and requires substantial processing time. A baseband system which does not

use the RF hardware should require less computation and may be able to implemented in

a real-time system.

4 List of Additional Parts for the NI Hardware

4.1

Parts Purchased

4.1.1 Cables and Connectors

From SM Electronics

http://www.smelectronics.us/

SMA HFLEX cables

6 - 24'' long, .141'' diameter, Part #HF141-24-0101

6 - 48'' long, .141'' diameter, Part #HF141-48-0101

6 - 72'' long, .086'' diameter, Part #HF086-72-0101

6 - 6'' long, .086'' diameter, Part #HF086-06-0101

SMA Formable Semi-rigid cables

4 - 6'' long, .086'' diameter, Part #HC086-06-0101

SMA Flexible 26.5Ghz cables

6 - 12'' long, Part #RF085H-0101-12

4.1.2 Adapters

SMA/SMA Straight 18Ghz Adapters

4 - SMA Female/Female Au(Gold) Plating, Part #4951

4 - SMA Female/Female Bulkhead Au Plating, Part #5205/Au

SMA-TNC Adapters

6 - SMA/Female - TNC/Female adapter, Part #5018

4.1.3 Splitters

From www.minicircuits.com

ZMSC-3-2 with an SMA connector, a 3-way power divider. Quantity 2

4.1.4 Antennas

There they have under their PCS and Dual Band Cellular Mobile Antenna

section they have Andrew Antenna Specialist Magnetic Mount Antennas with a

TNC connector, Item #97938

900mhz/1.8Ghz

Here is a direct link to the antenna

http://www.tessco.com/products/inv_display.jsp?gsg=36110&selsku=97938&cs=1

2.4Ghz Antennas

http://www.tessco.com/products/inv_display.jsp?gsg=36061&selsku=79798&cs=1

4.1.4 Amplifiers

Low Noise Amp

http://www.minicircuits.com/dg03-172.pdf

ZQL-2700MLNW (this is the one we currently have)

4.2

Planned Purchases

4.2.1 Amplifiers

From minicircuits

ZKL-2R7 http://www.minicircuits.com/cgi-bin/spec?cat=amplifier&model=ZKL2R7&pix=by493.gif&bv=4

4.2.2 Cables

www.pasternack.com

SMA-SMA low loss double shielded coax cables (Model No. PE3138)