Precision Die Casting: Process, Advantages, and Materials

advertisement

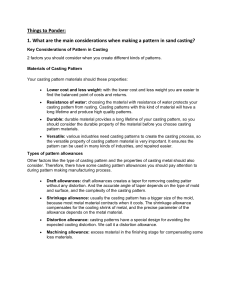

What Is Precision Die Casting Precision die casting is a manufacturing process used to create metal parts for a variety of industries. It can produce intricate and complex shapes. During the die casting process, metal is injected into a steel mold and then solidified. Using this technique, manufacturers can produce a wide range of parts from automotive to medical equipment. Precision die casting is a manufacturing process that creates parts in a repeatable, precise manner. It is commonly used in the automotive, medical, and aerospace industries among others. This process requires reusable steel molds called dies to produce a wide variety of engineered industrial, commercial, and consumer parts.The die casting process is a cost-effective alternative to other metal casting methods such as injection molding or sand casting, which require costly and time-consuming tooling to create the part. The die-casting process also produces high-quality, durable products. Another important advantage of the die-casting process is that it produces a high volume of products with very close tolerances, which eliminates the need for machining or stamping after the casting process. This saves energy and labor costs, and reduces waste and environmental pollution.A variety of materials can be used to make die-cast parts, including aluminum, magnesium alloys, and zinc. These alloys are lightweight yet tough and durable, and can be shaped into various shapes to meet the requirements of the end use application.