Manufacturing Processes

advertisement

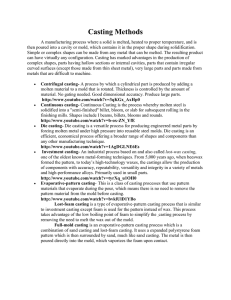

Basic Machine Processes Competency D403.00 Identify the basic concepts of the manufacturing processes. Basic Machine Processes Objective D403.01 Explain the concepts of the manufacturing process. Manufacturing Arrived from the Latin word “manu factus”, meaning “made by hand”. Manufacturing is the process of converting raw materials into products. WHY STUDY MANUFACTURING PROCESSES? The designer and the drafter must have a working knowledge of the various processes that could produce a part in order to: lower cost and reduce production time. Three Phases Of The Manufacturing Process 1. 2. 3. Product design. Selection of materials. Selection of production methods and techniques. The information needed to produce a part, most often comes in the form of a: Working Drawing Three Main Stages Of The Production Of A Machined Part Rough Forming Casting, Forging, Welding Finishing Drilling, machining, surfacing Assembling The assembly of parts The Casting Process First a pattern is made. Then a cavity is made by placing a pattern in wet sand. Next molten metal is poured into the cavity of damp sand. The Casting Process Rough Casting Machined Finish The rough casting is now ready for the machine shop. Holes are then bored and reamed. Top and bottom surfaces are machined Smaller holes will be drilled and counterbored. All corners on cast parts are fillets and rounds. Forging Process Forging is produced by using heavy mechanical presses or hammering heated bars of metal between dies. Advantages of forging over sand casting are that forged parts are much stronger and less brittle. Welding Welded Cast Welding is the fusion or joining of two pieces of metal by means of heat, with or without the application of pressure. Manufacturing Materials Fall into three general categories: 1. 2. 3. Metal Plastic Inorganic materials Metals are classified as: Ferrous - contain iron and steel. Nonferrous - do not have iron content (such as copper and aluminum). Alloys - mixture of two or more metals. Inorganic Materials Include: • Carbon and graphite - have low tensile strength (ability to be stretched). • Ceramics are clay and glass materials. (resistant to heat, chemicals, & corrosion). Heat-Treating: Annealing – is the process generally used to soften metal by heating followed by slow cooling. Hardening – requires heating and then rapid cooling in oil or water. Plastics Processing The plastics industry represents one of the major manufacturing segments. Thermosetting – becoming permanently hard and unmoldable when once subjected to heat. Thermoplastic – becoming or remaining soft and moldable when subjected to heat. Typical Plastic Processing Operations Include: Extrusion Blow Molding Injection Molding Thermoforming Extruding The process of producing shapes by forcing hot metal through a die that has and opening of the desired shape. Blow Molding Used in the production of bottles, automotive ductwork, hollow toy components, and door panels. Injection Molding . Used to manufacture products such as housings for electronic implements, automotive components, food storage containers, and components for medical applications. Thermoforming Used in the manufacturing of thin-walled packages for the food industry. Manufactured primarily by injection molding. CAD in Manufacturing The process of developing a design drawing on a CAD system and producing it on a computerized machine is called CAD/CAM. The process of converting the CAD drawing into a preprogrammed, coded instructions is called Computer Numerical Control (CNC). The advantages of the (CNC) is, better production and control, increased productivity, decreased labor and lower production costs. The Machinist Steel Ruler Commonly used measuring tool for getting rough measurements on a part. The smallest division on the fractional scale is 1/64” (.016). Vernier Caliper Precise measuring. Decimal, fractional, or metric. Often used by drafters to record dimensions from a machined prototype or part. 6” Dial Caliper Step Inside Inside Outside Depth 4-way Measurement 6” Dial Caliper – Three Scales METRIC (mm) FRACTIONAL (1/64”) DECIMAL (.XX)