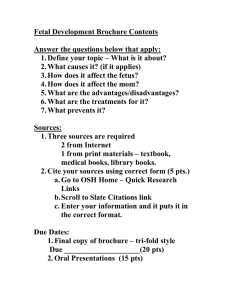

ME 482 – Final Exam

advertisement

ME 482 – Final Exam

Dec. 21, 2006

Name_____Solution_______

Problems

(20)

1.

Consider the technical papers and PPT presentations in class to arrive at the T/F answer for the following:

a.

DIP stands for dual integrated processor

T___

F_X_

b.

Surface mounted components cannot be passed through a wave solder.

T___

F_X_

c.

Bending springback lessens as the die radius is reduced.

T___ F_X_

d.

For metals in the elastic range the stress versus strain relation is exponential.

T___ F_X_

e.

In metal cutting the primary cutting parameters are feed, speed, and depth of cut.

T_X_ F___

f.

Machining tolerances typically improve as the part size decreases.

T_X_ F___

g. In FMS bottleneck analysis, fijk (operation frequency) is always equal to 1.

T___ F_X_

h.

In high speed machining, most of the cutting energy is converted to dynamic energy.

T_X_ F___

i.

A perfect just-in-time system with no delays between stations will have WIP.

T_X_ F___

j.

A Kanban system is a process rather than inventory control system.

T___ F_X_

k.

Next to diamond, cubic boron nitride is the hardest material known.

T_X_

F___

l.

The Czochralski process is a semiconductor crystal-growing method.

T_X_

F___

m. As friction increases in rolling the maximum pressure point moves towards the exit.

T___ F_X_

n.

Ball grid arrays can provide more contact points than square leaded chip carriers.

T_X_ F___

o.

In surface mounted assembly a screening process deposits the paste on the board.

T_X_ F___

p.

In turning, surface finish is a linear function of the feed for a single point tool.

T___ F_X_

q.

Indirect extrusion consumes more power than direct extrusion.

T___ F_X_

r.

Stress/strain metal springback in the plastic region is at a slope equal to Young’s modulus.T_X_ F___

s.

Some surface mount assembly machines can place > 10 parts per second on the board.

t.

The electronics manufacturing paper showed an alternative process to screen templates for

attaching surface mounted components to boards.

T___ F_X_

T_X_ F___

2

(20)

2. List the primary steps used to both manufacture and populate an IC board with surface mounted

components.

Manufacture:

1. Prep board (tabs, slots, holes, barcode, etc.) and drill tooling and via holes

2. Image and etch circuit patterns on board layers

Grading:

3. Sandwich/glue the layers and plate the via holes

Assemble (and Test):

1. Manufacture steps (get at least 2 steps)

2. Assembly steps (get at least 6 steps)

8 pts

12 pts

Assemble screen template for board type

Use vision to align template and adjust relative to board using standoff from board

Develop proper screen paste roll and adjust mechanical parameters until paste distributed

properly on IC board pads.

4. Apply paste to each board in batch.

5. Also apply epoxy if board has through hole parts and must be passed over wave solder.

6. Assemble board using assembly machine and possible some hand assembly for odd-form

components.

7. Pass board through heat flow oven to reflow solder paste

8. Inspect board for bridging and other assembly problems.

9. Test circuit continuity using tester.

10. Thermally perform stress tests.

11. If fails 10. or 11., then pass board to rework, else process completed.

1.

2.

3.

(20)

3. The yield of good chips in multiprobe for a certain batch of wafers is 83 %. The wafers have a nominal

diameter of 150 mm with a processable area that is 135 mm in diameter. If the defects are all assumed to

be point defects that are indistinguishable on the board, what is their density D?

Solution:

A = 14,313 mm2 = 143.13 cm2

Bose-Einstein Solution:

Eq. (35.15): Ym = 1/(1 + AD)

0.83 = 1/(1 + 143.13 D)

0.83(1 + 143.13D) = 0.83 + 118.8 D = 1

118.8 D = 1 - 0.83 = 0.17

D = 0.00143 defects/cm2

Grading:

1. Area calculation

2. Correct application of equations

3. Poisson soln

4. Bose-Einstein soln

5 pts

5 pts

5 pts

5 pts

3

(20) 4.

A single pass rolling operation reduces a 20 mm thick plate to 18 mm. The starting plate is 200 mm wide,

roll radius is 250 mm, and rotational speed is 12 rpm. The work material has a strength coefficient of 600

MPa and a strain hardening exponent = 0.22. Determine (a) roll force, (b) roll torque, and (c) power

required for the operation.

Solution:

(a) Draft = d = 20 – 18 = 2 mm

Contact length = L = (250x2)0.5 = 22.36 mm =0.02236 m

True strain = = ln(20/18) = 0.1054

Grading:

1. Contact length

2. Rolling force

3 Torque

4. Power

5 pts

5 pts

5 pts

5 pts

Yf = 600(0.1054)0.22/1.22 = 300 MPa

Rolling force = F = 300(0.02236)(0.2) = 01.342 MN = 1,342,000 N

(b) Torque = T = 0.5(1,342,000)(0.02236) = 15,000 N-m

(c) Given N = 12 rpm, Power = P = 2(12/60)(1,342,000)(0.02236) = 37, 700 W

(20)

5.

A titanium bar with a starting diameter of 500 mm and length of 1000 mm bar is to be turned. Cutting

conditions are f = 0.4 mm/rev and d = 3 mm. The cutting tool is cemented carbide with parameters n =

0.23 and C = 400. Using Taylor units of min for time and m/min for speed, compute the cutting speed that

will allow the tool life to just equal the cutting time for the part after one pass of length 1000 mm.

Solution:

N = v/(D)

eqn (22.1)

Tr (min) = time per revolution = 1/N = D/v

Tp (min) = time for one pass = L /(f/T r) = LTr/f = LD/(fv) where L = 1000 mm = bar length.

Set Tp equal to the life of the tool, where vT n = C (see eqn (23.1)); thus,

Tp = T = (C/v)1/n = L D/(fv)

Solving for v,

v(1-n)= C [f/(L D)]n

v0.77 = 400[(0.4)(1000)/{(3.142)(1000)(500)}] 0.23

Solving, v = 202.19 m/min

Grading:

1. Time per rev

2. Time for pass

3. Set times equal

4. Correct answer for v

5 pts

5 pts

5 pts

5 pts