Steam power plants 1

advertisement

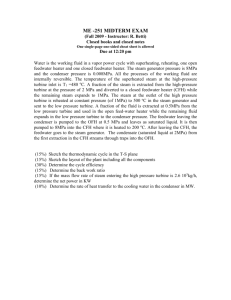

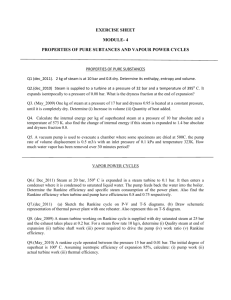

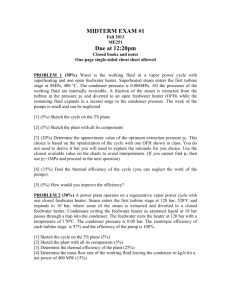

2/17/2013 University of Hail Faculty of Engineering DEPARTMENT OF MECHANICAL ENGINEERING ME 435 – Thermal Power Plants Lecture notes Steam power plants; Rankine cycle Part I Prepared by : Dr. N. Ait Messaoudene Based on: El-Wakil, Power Plant Technology, McGraw-Hill, 1984. 2nd semester 2012-2013 Shoaiba Steam Power Plant The power station consists of 11 units with a total capacity of 4,400 MW. After completing the third stage, the power station will consists of 14 units with total capacity of 5,600 MW, which makes it one of the largest fossil fuel-fired power stations in the world. The expansion will be built by Alstom and it expected to become operational by 2010.[2] The oil for power production is supplied from Saudi Aramco by tankers. 1 2/17/2013 Introduction Ideal cycle: Carnot cycle; but not suitable for steam (liquid-vapor phases) Ideal Rankine cycle: accepted as the standard for steam power plants. 2 2/17/2013 IDEAL RANKINE CYCLE: THE IDEAL CYCLE FOR VAPOR POWER CYCLES 1-2 Isentropic compression in a pump 2-3 Constant pressure heat addition in a boiler 3-4 Isentropic expansion in a turbine 4-1 Constant pressure heat rejection in a condenser Be careful! Temperature of cooling medium must be lower State 1: Saturated liquid Energy Analysis of the Ideal Rankine Cycle All four processes that make up the Rankine cycle can be analyzed as steady-flow processes. ke and pe changes of the steam are usually small relative to the W and Q terms The steady-flow energy equation per unit mass of steam reduces to : Incomp.. Liq. Pump (q = 0 + rev. or isentropic) where Boiler (w = 0 + p=cte) Turbine(q = 0 +rev. isentropic) Condenser (w = 0 + p=cte) 3 2/17/2013 The thermal efficiency of the Rankine cycle is determined from where The conversion efficiency of power plants in the United States is often expressed in terms of heat rate, which is the amount of heat supplied, in Btu’s, to generate 1 kWh of electricity. Considering that 1 kWh = 3412 Btu Superheating the Steam to High Temperatures (Increases Thigh,avg) Limited by materials More heat input but net gain in work Other advantage: increases x4 4 2/17/2013 One way for increasing efficiency is to increase boiler pressure; but this also has negative effects Increase in Thigh,avg so increase in efficiency Two solutions: Superheat steam to very high temperature (Increase T3) But disadvantage: increases x4 But not viable because of materials limitations Expand the steam in two-stage turbine (HP and LP) , and reheat it in between. Reheating is a practical solution and is commonly used in modern steam power plants 5 2/17/2013 Thus the total heat input and the total turbine work output for a reheat cycle become 6 2/17/2013 ( + the fact that T5 = T3) ( = 1.0 – 0.104 ) wet vapor or sat. mixt. state 7 2/17/2013 8 2/17/2013 THE IDEAL REGENERATIVE RANKINE CYCLE In a simple Rankine cycle, heat is transferred to the working fluid at a relatively low temperature as it enters the boiler. This lowers the average heat addition temperature and thus the cycle efficiency. To remedy this shortcoming, we look for ways to raise the temperature of the liquid leaving the pump (called the feedwater) before it enters the boiler by using some of the heat of the cycle. This is called regeneration. A practical regeneration process in steam power plants is accomplished by extracting, or “bleeding,” steam from the turbine at various points. This steam, which could have produced more work by expanding further in the turbine, is used to heat the feedwater instead. The device where the feedwater is heated by regeneration is called a regenerator, or a feedwater heater (FWH). A feedwater heater is basically a heat exchanger where heat is transferred from the steam to the feedwater by mixing the two fluid streams (open feedwater heaters) without mixing the two streams (closed feedwater heaters) DEVIATION OF ACTUAL VAPOR POWER CYCLES FROM IDEALIZED ONES common sources of irreversibilities: fluid friction and heat loss to the surroundings A particular attention is given to losses due to irreversibilities within the pump and the turbine Other losses to be considered : subcooling of the liquid in actual condensers to prevent the onset of cavitation, losses at the bearings between the moving parts, steam leaks (out), air leaks (in), power consumed by the auxiliary equipment (such as fans that supply air to the furnace)… 9 2/17/2013 pressure drop Heat loss + pressure drop Friction 10 2/17/2013 11 2/17/2013 Specific volume=1/r Note: No need to use J when working in SI units 12 2/17/2013 13 2/17/2013 Mass and energy balance on a unit mass flowrate basis 14 2/17/2013 Note: No need to use J when working in SI units 15