International Association of Scientific Innovation and Research (IASIR)

(An Association Unifying the Sciences, Engineering, and Applied Research)

ISSN (Print): 2279-0020

ISSN (Online): 2279-0039

International Journal of Engineering, Business and Enterprise

Applications (IJEBEA)

www.iasir.net

Evaluation of the mechanical properties of core and plated spandex blend

knits

N.Gokarneshan1 and K.Thangamani2*

NIFT - TEA College of Knitwear Fashion, Tirupur – 641 606, India.

2

Department of Textile Technology, Kumaraguru College of Technology, Coimbatore –

641 006, India.

_________________________________________________________________________________________

Abstract: This paper investigates and compares the mechanical properties of core and plated cotton/spandex,

polyester/spandex and viscose/spandex blend knits. The properties considered here include air-permeability,

bursting strength, abrasion resistance, pilling resistance, and thickness. The different blends exhibit varying

trends in the properties examined, and the underlying reasons for these are discussed herein.

Key words: Blend knit, Spandex, core, plated, properties

__________________________________________________________________________________________

1

I. Introduction

One of the main objectives of knitted garments is to provide required stretch and comfort properties to

the human body. But the stretch and recovery in normal knitted fabrics is sufficient for certain applications. In

order to overcome this problem spandex, elastomeric filament with high stretch and recovery even at very large

extensions is used along with cotton/polyester as core spun[2003]. The blending of cotton and polyester with

spandex in core spun form improves the fabric elongation to a great extent and at the same time provides a

comfortable to the wearer. A great deal of work has been done in investigating the properties of knitted fabrics,

wherein several researchers have made their noteworthy contributions. Munden has evolved relating to the yarn

diameter and loop length [1959]. Marmarali investigated the dimensional and physical properties of cottonspandex plated single jersey knitted fabrics and compared their results with those of plain knits [2003]. A

considerable amount of work has been done on cotton single jersey fabrics on related aspects of their properties.

Very recently work has been reported on the dimensional characteristics [2010]. Knits have also gained wide

application in the areas of technical applications as recent researches point out [2008, 2009]. This paper

investigates the basic properties of core and plated blend knits so as to assess their suitability in technical

applications.

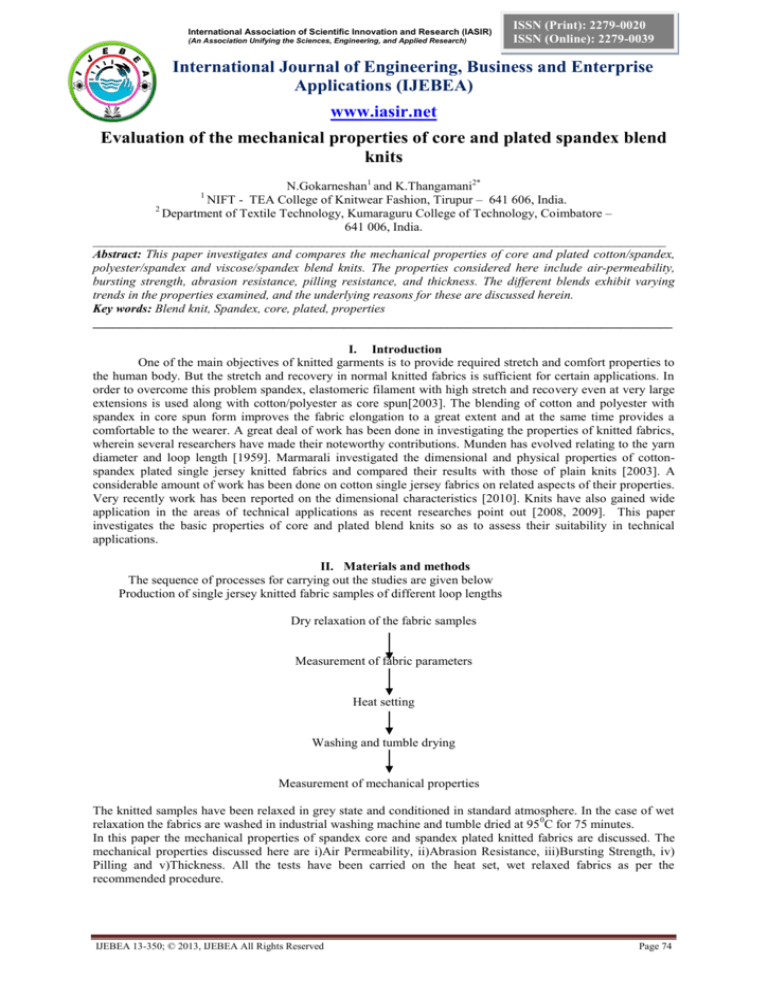

II. Materials and methods

The sequence of processes for carrying out the studies are given below

Production of single jersey knitted fabric samples of different loop lengths

Dry relaxation of the fabric samples

Measurement of fabric parameters

Heat setting

Washing and tumble drying

Measurement of mechanical properties

The knitted samples have been relaxed in grey state and conditioned in standard atmosphere. In the case of wet

relaxation the fabrics are washed in industrial washing machine and tumble dried at 95 0C for 75 minutes.

In this paper the mechanical properties of spandex core and spandex plated knitted fabrics are discussed. The

mechanical properties discussed here are i)Air Permeability, ii)Abrasion Resistance, iii)Bursting Strength, iv)

Pilling and v)Thickness. All the tests have been carried on the heat set, wet relaxed fabrics as per the

recommended procedure.

IJEBEA 13-350; © 2013, IJEBEA All Rights Reserved

Page 74

K.Thangamani et al., International Journal of Engineering, Business and Enterprise Applications, 6(1), September-November., 2013, pp. 7478

The measurement of air permeability is based on the rate of flow of air through a given area of fabric by giving

a pressure drop across the fabric (IS:11056-1984). Martindale abrasion tester is used to measure the abrasion

resistance, which is based on constant revolution method as per ISO 12947-2. The Bursting strength is

determined using hydraulic diaphragm bursting tester as per ISO 13938-1. The pilling grade is evaluated using

grade scale with specific ratings adopting the ISO – 12945 – Section – 1:2000 standard. The fabric thickness is

measured using the ISO 5084 and ASTM 1777-96 standards.

III. Results and discussion

A. Measurement of air-Permeability

The air permeability values of cotton/spandex and polyester/spandex plain knitted fabric and for

viscose/spandex plated plain knitted fabrics have been measured. It can be observed that air permeability values

of 15tex and 20tex cotton / spandex and 170d and 97d polyester/spandex plain knitted fabrics does not change

in a significant manner with the loop length .

Another observation that can be made is that finer the yarn lesser is the air permeability (fig1).When the yarn is

finer the air gaps within the yarn and between the yarn is reduced and hence the air permeability also is reduced.

AIR PERMEABILITY

Air permeability cm³/cm²/s

100

80

15te

x20te

x170

d97d

60

40

20

0

10

12

14

16

18

Tightness factor

Fig. 1 Air permeability of cotton/spandex and polyester /spandex plain knitted fabrics

Air permeability

(cm³/cm²/s)

VSP-AIR PERMEABILITY

140

120

100

80

60

40

20

0

No plating

Half plated

Full plated

14

14.5

15

15.5

16

16.5

17

Tightness factor

Fig. 2 Air permeability of viscose/spandex plated plain knitted fabrics

In the case of full plated fabrics the air permeability is drastically less compared to half plated and 100% viscose

fabric. As the spandex content is more the fabric becomes tighter and hence less air permeability. Within the

same spandex content the air permeability increases with increase in loop length or decrease in tightness

factor.(fig.2)

B. Abrasion Resistance

The abrasion resistance of 15tex and 20tex cotton/spandex plain knitted fabrics and for viscose /spandex plated

fabrics have been measured. The abrasion resistance is plotted against tightness factor.

It can be observed that under normal testing conditions the abrasion resistance of 15tex and 20tex fabric it

remains more on less constant at 99%. The abrasion resistance of 170d and 97d polyester /spandex fabrics is

almost 100%.(fig.3)

As in the case of cotton / spandex and polyester / spandex fabrics the viscose/ spandex plated fabrics also show

high abrasion resistance (fig.4). The abrasion resistance for half plated fabric is around 97% and for full plated

fabric is around 99%. Here a slight decrease in abrasion resistance for increase in loop length can be observed.

IJEBEA 13-350; © 2013, IJEBEA All Rights Reserved

Page 75

K.Thangamani et al., International Journal of Engineering, Business and Enterprise Applications, 6(1), September-November., 2013, pp. 7478

105

100

20tex

95

15tex

90

170d

97d

85

16

14

.7

13

.3

12

.5

11

.4

10

.7

17

80

16

.9

15

.4

14

.5

14

.2

12

.9

11

.9

Abrasion resistance (%)

ABRASION RESISTANCE

Tightness factor

Fig. 3 Abrasion resistance of cotton/spandex and polyester/spandexplain knitted fabrics

VSP-ABRATION RESISTANCE

Abration resistance %

100

98

96

No plating

94

Half plated

92

Full plated

90

88

16.5 15.4 14.4 16.5 15.4 14.4 16.5 15.4 14.4

Tightness factor

Fig. 4 Abrasion resistance of viscose/spandex plated plain knitted fabrics

C. Bursting strength

The bursting strength of cotton / spandex knitted and polyester/spandex fabric have been determined. It has been

observed that the bursting strength is lower for 15tex fabric than for 20tex fabrics which is obvious due to the

higher single yarn strength for 20tex. In both cases the bursting strength decreases with decreases in tightness

factor. As the tightness factor decreases the fabric becomes loose, hence bursting strength also is lower. The

bursting strength of 170d fabrics are higher than the 97d fabrics and it slightly decreases with tightness factor.

However, the decrease in bursting strength with tightness factor in 97d fabrics is marked. In fig. 5 and fig. 6 the

bursting strength of cotton /spandex and polyester/spandex fabrics are shown.

Bursting strength (kg/cm²)

BURSTING STRENGTH

14

12

10

20tex

8

15tex

6

170d

4

97d

2

10.7

11.4

12.5

13.3

14.7

16

17

11.9

12.9

14.2

14.5

15.4

16.9

0

Tightness factor

Fig. 5 Bursting strength of cotton /spandex and polyester /spandex plainknitted fabrics

Bursting strength (kg/cm²)

VSP-BURSTING STRENGTH

6

5

4

No plating

3

Half plated

2

Full plated

1

0

16.5 15.4 14.4 16.5 15.4 14.4 16.5 15.4 14.4

Tightness factor

Fig. 6 Bursting strength of viscose/spandex plated plain knitted fabrics

IJEBEA 13-350; © 2013, IJEBEA All Rights Reserved

Page 76

K.Thangamani et al., International Journal of Engineering, Business and Enterprise Applications, 6(1), September-November., 2013, pp. 7478

In viscose plated fabrics bursting strength increases with increase in plating level. The bursting strength for half

plated fabrics is between 3.5 to 3.85 kg /cm2. And for full plated fabrics it is between 4.5 to 5.0 kg / cm2. Within

the same spandex content the bursting strength decreases with increase in loop length.

D. Pilling

The pilling grades of cotton/spandex and polyester/spandex knitted fabrics are given in Figure 7

It can be observed from the fig.7 that the pilling grades of 15tex fabrics are poor in all the cases. The pilling

grades of 20tex fabrics are good for higher tightness factors of 16.9 and 15.4 and medium for lower tightness

factor of 14.5. Therefore, we can conclude that for a good pilling grade the tightness factor should be above

15.4. The pilling grades of cotton/spandex fabrics are given. in fig 8.

CS-PILLING

5

Pilling grade

4

3

15tex

2

20tex

1

0

14.2

12.9

11.9

16.9

15.4

14.5

Tightness factor

Fig. 7 Pilling grades of cotton/spandex plain knitted fabrics

PS-PILLING

5

Pilling grade

4

3

170d

2

97d

1

0

17

16

14.7

13.3

12.5

11.4

10.7

Tightness factor

Fig. 8 Pilling grades of polyester/spandex plain knitted fabrics

VSP-PILLING

5

Pilling grade

4

No plating

3

Half plated

2

Full plated

1

0

16.5

15.4

14.4

16.5

15.4

14.4

16.5

15.4

14.4

Tightness factor

Fig. 9 Pilling grades of viscose/spandex plated plain knitted fabrics

The pilling grades of 170d and 97d polyester /spandex knitted fabrics are very good for all the tightness factors

because the polyester is in filament form. The pilling grades for polyester/spandex fabric are given in fig. 9

The pilling grades of viscose /spandex plated knitted fabrics have been assessed. For viscose /spandex plated

knitted fabrics the plating level increases the pilling grade. The pilling grade is 1-2 for fabrics without plating, 23 for half plated fabrics and 3-4 for full plated fabrics.

E. Thickness

The thickness of 15tex and 20tex cotton / spandex fabric and 170d and 97d polyester/spandex fabrics for various

tightness factor have been determined. It has been observed that for 15tex and 20 tex cotton / spandex fabrics as

the tightness factor increases the structure becomes compact and as a result the thickness decreases.

The thickness of 170d and 97d polyester/spandex fabrics also the thickness decrease as the tightness factor

increases. This may be due to the reason that as the fabric becomes tighter it becomes more compact resulting in

reduction in thickness. In fig.10 thickness of cotton/spandex and polyester /spandex fabrics have been plotted

against tightness factor.

For viscose /spandex plated fabrics the fabric thickness for various loop lengths and plating levels have been

measured. It has been observed that the fabric thickness is highest for full plated fabrics followed by half plated

IJEBEA 13-350; © 2013, IJEBEA All Rights Reserved

Page 77

K.Thangamani et al., International Journal of Engineering, Business and Enterprise Applications, 6(1), September-November., 2013, pp. 7478

fabrics and least for 100% viscose. It can also been seen that the fabric thickness increases with loop length.

Figure 11 shows the fabric thickness for viscose plated fabrics. The fabric thickness is more at higher loop

lengths due to the bulky effect of the fabric at higher loop length. As the tightness factor increases the thickness

decreases.

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

20tex

15tex

170d

16

14

.7

13

.3

12

.5

11

.4

10

.7

17

97d

16

.9

15

.4

14

.5

14

.2

12

.9

11

.9

Thichness(mm)

THICKNESS

Tightness factor

Fig. 10 Thickness of cotton/spandex and polyester /spandex Plain knitted fabrics

VSP-THICKNESS

Thickness(mm)

1

0.8

No plating

0.6

Half plated

0.4

Full plated

0.2

0

14

14.5

15

15.5

16

16.5

17

Tightness factor

i)

ii)

iii)

iv)

v)

Fig. 11 Thickness of viscose /spandex plated plain knitted fabrics

IV. Conclusion

Air permeability remain constant irrespective of count and loop length for cotton/spandex fabrics where as

it decreases with increase in loop length for 97d polyester /spandex fabrics. For viscose /spandex plated

plain knitted fabrics air permeability is influenced by spandex content and loop length. It decreases with

increase with spandex content and increases with loop length

Abrasion resistance for cotton/spandex and polyester /spandex fabrics are good at nearly 99-100% .For

viscose /spandex plated knitted fabrics increase in plating level increases the abrasion resistance.

Bursting strength of cotton/spandex fabrics decrease with loop length and course count fabrics have more

bursting strength. The bursting strength of polyester /spandex fabrics are more than that in viscose

/spandex plated knitted fabrics the and plating level increases the bursting strength.

The pilling grade of cotton /spandex fabrics are poor where as the pilling grade of polyester /spandex

fabrics are good. The increase in spandex content in viscose /spandex plated fabrics improves the pilling

grade.

The thickness of both cotton /spandex and polyester /spandex fabrics decreases with increase in tightness

factor. For viscose /spandex plated knitted fabrics the thickness increases with increase in spandex content.

REFERENCES

1.

2.

3.

4.

5.

6.

Bhuvanesh G & Nilesh R 2009, “Development and structural evaluation of PLA based knitted scaffold for human urinary bladder

reconstruction”, Indian journal of fibres and textile research, Vol.34,., 115-121.

Gokarneshan N, & Thangamani K 2010, An investigation into the properties of

cotton/spandex and polyester/spandex knitted

fabrics, Journal of the textile institute, Vol.101, No.2, 182.

Kirk W M Jr. 1963, “Lycra Spandex fibre-structure and properties” American dyestuff reporter, 725-727.

Marmarali AB 2003, Dimensional and physical properties of cotton/spandex single jersey fabrics, Textile research journal, 73(1),

11.

Munden DL 1959, The geometry and dimensional properties of plain knit fabrics, Journal of the Textile Institute, 50, 448 – 471,.

Anand S 2008, Designer natural fibre geotextile – A new concept, Indian journal of fibre and textile research, Vol.33, 339-344.

IJEBEA 13-350; © 2013, IJEBEA All Rights Reserved

Page 78