ENGR 40434– INTRODUCTION OF MEMS

advertisement

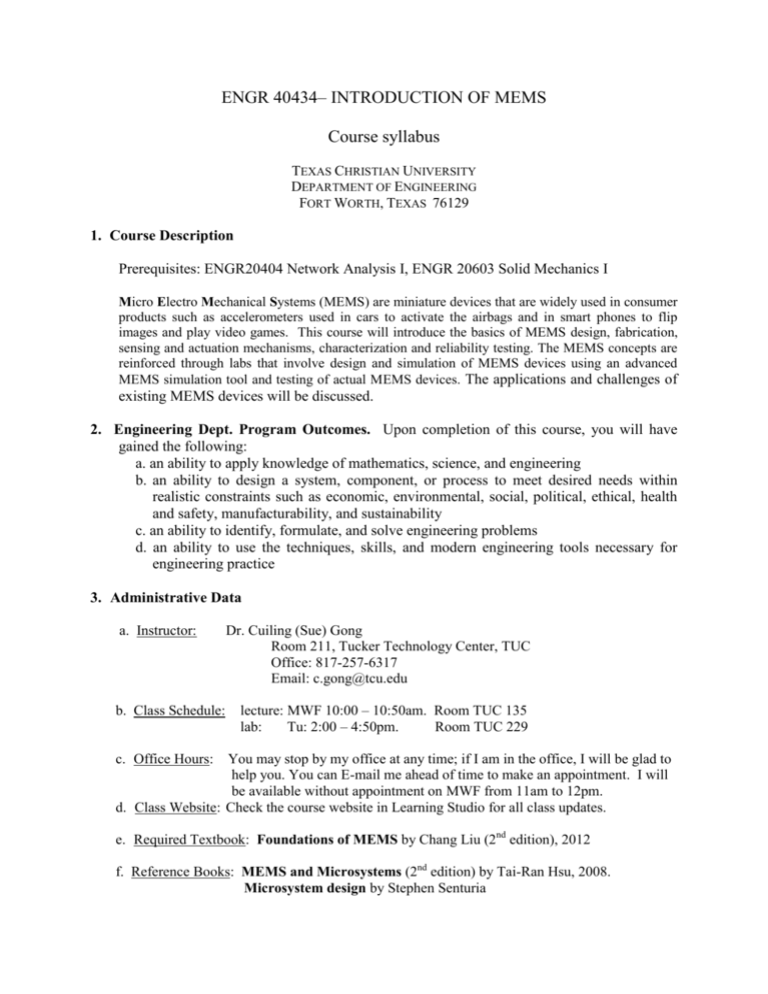

ENGR 40434– INTRODUCTION OF MEMS Course syllabus TEXAS CHRISTIAN UNIVERSITY DEPARTMENT OF ENGINEERING FORT WORTH, TEXAS 76129 1. Course Description Prerequisites: ENGR20404 Network Analysis I, ENGR 20603 Solid Mechanics I Micro Electro Mechanical Systems (MEMS) are miniature devices that are widely used in consumer products such as accelerometers used in cars to activate the airbags and in smart phones to flip images and play video games. This course will introduce the basics of MEMS design, fabrication, sensing and actuation mechanisms, characterization and reliability testing. The MEMS concepts are reinforced through labs that involve design and simulation of MEMS devices using an advanced MEMS simulation tool and testing of actual MEMS devices. The applications and challenges of existing MEMS devices will be discussed. 2. Engineering Dept. Program Outcomes. Upon completion of this course, you will have gained the following: a. an ability to apply knowledge of mathematics, science, and engineering b. an ability to design a system, component, or process to meet desired needs within realistic constraints such as economic, environmental, social, political, ethical, health and safety, manufacturability, and sustainability c. an ability to identify, formulate, and solve engineering problems d. an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice 3. Administrative Data a. Instructor: b. Class Schedule: Dr. Cuiling (Sue) Gong Room 211, Tucker Technology Center, TUC Office: 817-257-6317 Email: c.gong@tcu.edu lecture: MWF 10:00 – 10:50am. Room TUC 135 lab: Tu: 2:00 – 4:50pm. Room TUC 229 c. Office Hours: You may stop by my office at any time; if I am in the office, I will be glad to help you. You can E-mail me ahead of time to make an appointment. I will be available without appointment on MWF from 11am to 12pm. d. Class Website: Check the course website in Learning Studio for all class updates. e. Required Textbook: Foundations of MEMS by Chang Liu (2nd edition), 2012 f. Reference Books: MEMS and Microsystems (2nd edition) by Tai-Ran Hsu, 2008. Microsystem design by Stephen Senturia ENGR 40434 Outline Week #1 #2 #3 #4 #5 #6 #7 #8 Subject Course Introduction Lab introduction Microfabrication Silicon as MEMS material Holiday – no class Basic processes: Photolithography Lab 1: CoventorWare: build a 3D model Silicon doping and oxidation Deposition and etching Micromachnining Lab 2: CoventorWare: model and stress analysis using MemMech, Spring MM, meshing study Bulk micromachining – wet etching Bulk micromachining – dry etching Surface micromachining -processes Lab 3: Electrical analysis of comb drives Surface micromachining - stiction, residual stress LIGA and electroplating Actuation and Sensing Lab 4: Coupled Electro-thermal-mechanical analysis: Thermal actuator Elelctrostatic actuation (parallel plate) Elelctrostatic actuation (comb drive) Elelctrostatic sensing Lab 5: micromirror design Piezoelectric actuation Piezoelectric sensing Thermoelectric sensing and actuation No lab Review Mid-term Design and Modeling Lab 6: piezoelectric frequency sensor design Design considerations Scaling in miniaturization Finite Element analysis Lab7: MEMS testing reading and HW HW1 due Quiz 1 HW2 due Quiz 2 HW#3 due #9 #10 #11 #12 #13 #14 #15 Examples Packaging & Assembly wire bonding and encapsulation Surface bonding and 3D packaging Wafer level packaging Signal integrity MEMS characterization Lab 8: MEMS switch as logic gates characterization techniques MEMS Testing and Reliabilities Accelerated testing Lab 9: project assignment – RF MEMS Lecture by guest speaker Applications Acoustic MEMS: Microphones Lab 10: Lab on a chip demo/project Opitcal MEMS: micromirrors Microfluidics Lab 11: Field trip to Texas Instruments: DLP Products Inkjet head Piezoelectric energy harvester Nano technologies Lab12: project presentation Principles, applications and challenges Course Review study day – no class Final Exam: 11:30~2pm Quiz #3 HW #4 due Quiz #4 HW #5 due Quiz #5