PDF - Intrigo Systems

advertisement

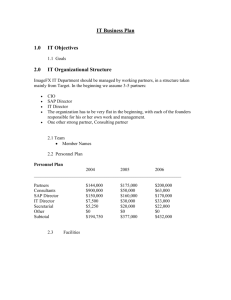

1 | Infinera Confiden-al & Proprietary Shop–floor to Top-­‐floor with SAP MII 2 | Infinera Confiden-al & Proprietary About Infinera ê ê ê ê ê Founded in 2001 Headquartered in Sunnyvale, CA $450M annual revenue 1,000 + employees worldwide Manufacturer of long-­‐haul WDM op-cal transmission equipment for telecommunica-ons service providers and enterprises ê Chip designed and manufactured in-­‐ house 3 | Infinera Confiden-al & Proprietary About Intrigo is a solu(on provider of Business Applica-ons focused on orchestra(ng Customer Value Networks in the changing SAP Enterprise technology landscape. CLOUD VIRTUAL S&OP DSIM Sen1ment SOCIAL Enterprise On HANA Track & Trace Innova1on Sequencing 4 | Infinera Confiden-al & Proprietary IN-­‐MEMORY BI MOBILE BIG DATA Where We Were ê Three manufacturing facili-es located in two loca-ons; Sunnyvale, CA & Allentown, PA • Semiconductor Chip Manufacturing facility – Sunnyvale, CA • Module & System Manufacturing & Tes-ng facility – Allentown, PA • System manufacturing & Tes-ng facility – Sunnyvale, CA ê Each of the facili-es had their own manufacturing systems, all home grown ê None of the manufacturing systems were integrated to the corporate ERP system ê Local report based management of supply chain 5 | Infinera Confiden-al & Proprietary Driving Forces for Change ê Shop-­‐floors disconnected to overall supply chain; -me lag to react to change in demand and supply ê Customer demands translated manually to local systems; prone to errors ê Local stock policy in each system; driving excess inventory at all stages of manufacturing ê No visibility of inventory in the supply chain; unable to provide accurate feedback to customer inquiries ê Understanding of cost and profitability was post-­‐period close; unable to make adjustments mid-­‐period 6 | Infinera Confiden-al & Proprietary Solu-on Implemented ê Solu-on deployed in two phases • Phase 1 – covered two of the three manufacturing facili-es; part of the overall SAP ECC implementa-on • Phase 2 – deployment for the semiconductor chip manufacturing ê Different approaches for each facility, managed with a single architecture for interface and integra-on ê Overall components used in the solu-on design • SAP ECC for produc-on orders, cos-ng, and profitability analysis • SAP MII for interfacing MES systems to SAP ECC • Web-­‐dynpro for shop-­‐floor interface to SAP ECC 7 | Infinera Confiden-al & Proprietary Solu-on Implemented System Manufacturing & Tes(ng – Sunnyvale, CA ê Simple opera-ons with serial number tracking – non-­‐automated assembly line ê Legacy MES replaced with SAP SFC, crea-ng a single system of record for planning and ê ê ê ê execu-on Provided direct access with Web-­‐dynpro via distributed PI at each shop-­‐floor terminal Single sign-­‐on for ease of access Real-­‐-me informa-on on the work order being worked on Barcode interface to capture data 8 | Infinera Confiden-al & Proprietary Solu-on Implemented Module & System Manufacturing & Tes(ng – Allentown, PA ê Manufacturing of sub-­‐assemblies and modules ê Interfaced with MES via MII ê Serialized products ê Opera-ons mapped one-­‐to-­‐one with MES using standard text key ê Managed regular produc-on, rework orders with dynamic opera-on inser-ons and R&D work orders assigned to internal orders ê Two way crea-on of produc-on order; SAP à MES for regular produc-on & MES à SAP for rework orders 9 | Infinera Confiden-al & Proprietary Solu-on Implemented Semiconductor Chip Manufacturing – Sunnyvale, CA ê ê ê ê ê More complex manufacturing process Products are serialized and lot managed MES interfaced to SAP ECC via MII Milestone opera-ons of MES are mapped to SAP opera-ons Leveraged schemas available for ME integra-ons and interface logics developed for the module ê All work orders ini-ated from MES Generate SAP Requests Process Requests Queue (FIFO) Process SAP Response MES 10 | Infinera Confiden-al & Proprietary Process Transac1on Asynchronous calls Process Response MII Synchronous calls SAP Solu-on Implemented ê Complexi-es Managed • Master data integra-on to MES systems (Material and BOM) • Regular produc-on, repairs, R&D manufacturing with associa-on to projects / internal orders • Serial number based component consump-on, tracking and receipts • Batch number based component consump-on, tracking and receipts • Handling of alternates • Handling of co-­‐products • Handling of swap outs in manufacturing line • De-­‐install and install of components • Dynamic introduc-on of re-­‐work loops • Bar code based data collec-on • Real-­‐-me integra-on for cost accoun-ng and profitability analysis • Real-­‐-me integra-on to tes-ng machine to record results 11 | Infinera Confiden-al & Proprietary Benefits Realized ê Real-­‐-me visibility of manufacturing opera-on and WIP to central planning and execu-ves; able to make changes to the supply faster ê Complete transparency of cost of manufacturing; able to make correc-ve ac-ons, if required ê Real-­‐-me variance analysis and seglement; allowing for faster period close ê One system for all inventory and WIP ê Single source of truth 12 | Infinera Confiden-al & Proprietary Lessons Learned ê Analyze the various scenarios and events that occur in the MES system by looking at the data to establish the use cases for integra-on ê Don’t underes-mate the effort required on the MES development ê Begin unit tes-ng using MES data instead of mocked up files early in the project ê Get an agreement on the new way of measuring cycle -me, opera-ons -me, yields, manufacturing cost, etc. from manufacturing department owners 13 | Infinera Confiden-al & Proprietary What's Next? ê Expand the scope of MII for repor-ng leveraging the data monitoring and dash boarding capabili-es 14 | Infinera Confiden-al & Proprietary Thank You For more informa-on, please contact: 800-­‐440-­‐2137 info@intrigosys.com Intrigo Systems 42808 Christy Street, Suite 221 Fremont, CA 94538 www.intrigosys.com 15 | Infinera Confiden-al & Proprietary