Performix Inc Implementing MES in SAP Landscape

advertisement

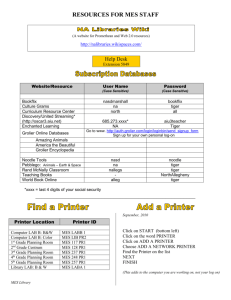

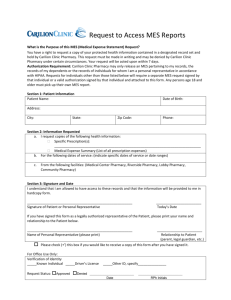

Performix Inc: Implementing MES in SAP Landscape Implementing MES in SAP Landscape Sham Afzalpurkar CEO, Performix Inc. September 26th, 2006 Introduction • Sham Afzalpurkar, CEO Performix Inc • About Performix • • • • • A Manufacturing Execution Systems company Developing xApps in MES space Significant Supply Chain, Manufacturing Execution &Track/Trace experience Focus on Pharmaceuticals, Process Industries and Hi Tech Offices in Houston, Texas with development teams in India Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned Why MES? • In the last decade, ERP and SCM have NOT delivered the expected returns • Focus on deploying MES solution to give visibility and flexibility and effectively manage supply chain • Competition has forced quality products at lower cost • Integration of ERP and MES has been a challenge • Standards such ISA 95 provide the potential to simplify deployment What is Manufacturing Execution System? • Co-ordinate functions on the shop floor to optimize the plant activities • Manufacturing Execution System provides effective integration between production processes and enterprise business systems. • Layer of communication between business and control systems ERP MES SHOP FOOR AUTOMATION Components of MES • Core • • • • • Material and Production Tracking Material Handling and Production Procedures Resource management and allocation Production Dispatching Data Collection • Extensions • • • • • • Compliance Quality Assurance Performance Analysis Detail Scheduling Document Management Labor Management What is ISA 95? • Instrumentation, Systems, and Automation Society (ISA) Standard • Standard that defines how to link Enterprise and Controls systems using a Manufacturing Execution Systems (MES) layer. This standard describes: • The MES Functionality • The Data base schema at the MES Level • The Messages between the Enterprise system and MES What is B2MML? • The World Batch Forum (WBF) has published XML schemas based on the S95 Model B2MML (Business to Manufacturing Markup “Hypertext” Language) • • • • • • • • • • B2MML-V0201-Common.xls B2MML-V0201-Personnel.xls B2MML-V0201-Equipment.xls B2MML-V0201-Material.xls B2MML-V0201-Maintenance.xls B2MML-V0201-ProcessSegment.xls B2MML-V0201-ProductionDefinition.xls B2MML-V0201-ProductionCapability.xls B2MML-V0201-ProducitonPerformance.xls B2MML-V0201-ProductionSchedule.xls MES vendors offer solutions that overlap functionality offered by SAP Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned Justifying MES – Business Drivers • Visibility of data globally • Standard processes • Enable benchmarking and best practices • • • • Consistent Documentation Resource Utilization Accurate and consistent KPI Seamless Integration Justifying MES - Benefits • Increases Operational Excellence • Lower Operating Costs • Asset Management • Reduced Total Cost of Ownership Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned Manufacturing Assessment & Planning • What are the business drivers? • What are the organizational and process related issues? • What should be done first – aligning manufacturing strategy with business strategy Business Functions (S95) Enterprise Performance Reporting Demand Planning Sales & Distribution Detail Scheduling Resource Management Supply Chain Planning Material Management Process Optimization Production Execution Production Planning Recipe Management WIP Material Management Cost Accounting Human Resource Management Warehouse Management Maintenance Management Performance Management Production History Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Process Analysis Quality Management Level 4 Business Planning & Logistics Level 3 Manufacturing Operations Level 2 Plant Floor Control Simple Discrete Enterprise Performance Reporting Demand Planning Sales & Distribution Supply Chain Planning Material Management Production Planning Detail Scheduling Resource Management Production Execution WIP Material Management Cost Accounting Human Resource Management Warehouse Management Maintenance Management Performance Management Process Analysis Production History Quality Management ERP Some PLCs Machines & Work Centers Fixed Routes, No Lot Splitting Only Ingredients Changes Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Aerospace and Automotive Complex Discrete Enterprise Performance Reporting Demand Planning Sales & Distribution Supply Chain Planning Material Management Production Planning Cost Accounting Human Resource Management Warehouse Management Maintenance Management Detail Scheduling Process Analysis ERP Resource Management Production Execution WIP Material Management Production History Quality Management MES Thousands of parts, complex procedures, many products Some PLCs Machines & Work Centers Production Lines Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Semiconductor Enterprise Performance Reporting Demand Planning Sales & Distribution Supply Chain Planning Material Management Production Planning Cost Accounting Human Resource Management Warehouse Management Maintenance Management ERP Detail Scheduling Resource Management Process Optimization Recipe Management Production Execution Performance Management WIP Material Management Production History Process Analysis Quality Management many shared resources, complex routing, many products MES thousands of parts, complex procedures Some PLCs Machines & Work Centers Production Lines Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Pharmaceuticals & Specialty Chemicals Enterprise Performance Reporting Demand Planning Sales & Distribution Supply Chain Planning Material Management Production Planning Cost Accounting Human Resource Management Warehouse Management Maintenance Management ERP Detail Scheduling Resource Management Process Optimization Production Execution Recipe Management Performance Management WIP Material Management Production History Process Analysis Quality Management many shared resources, large recipes, many products MES compliance, complex procedures SCADA / PCS Equipment Trains Flexible Connections Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Oil & Gas and Bulk Chemicals Enterprise Performance Reporting Demand Planning Sales & Distribution Supply Chain Planning Material Management Production Planning Cost Accounting Human Resource Management Warehouse Management Maintenance Management ERP Process Optimization Performance Management Production History SCADA / PCS Equipment Trains Fixed Connections Process Analysis Quality Management Real-Time Execution Real-Time SPC Real-Time Control Real-Time Monitoring Large number of control variables, real-time optimization MES Functionality • • • • • • • • • Dispatching and Production Resource Allocation Quality Management Data Collection Process Management Production Tracking and Genealogy Document Control Performance Analysis Operational Detail Scheduling Dispatching Production • Manages the flow of production in the form of jobs, orders, batches, lots and work orders by dispatching production to specific equipment and personnel. Includes information that is presented in the sequence in which the work needs to be done. Criteria Positioning Simple Recipe & Tracking SAP / PP or PPPI and APO Complex Recipes MES Complex Lot Management Consider xApp Resource Allocation & Status • Manage the resources directly associated with control and manufacturing. Criteria Positioning Manual & Simple Procedure SAP PP or PI Manual & Automated MES Data Collection & Acquisition Obtains operational production and parametric data associated with production equipment and processes. Provides real-time statuses of production equipment and processes. Criteria Positioning Discrete &/or low data volume SAP / PP or PP PI High speed real time data MES collection or very high volume Quality Management • Provides real-time measurements collected form manufacturing to assure proper product quality control and to identify problems requiring attention. Includes SPC / SQC tracking and management of offline inspection operations . Criteria Manual data collection Positioning SAP QM Real time measurements with MES / SAP xMII simple statistics Real time measurements with MES / SAP xMII multi-variable analysis Process Management • Monitors production and either automatically corrects or provides decision support to operators for correcting and improving in-process functions. It may include alarm management to handle process deviations. Criteria Positioning Manual SAP / PP or PPPI Automated Systems MES Complex Recipes MES Production Tracking & Genealogy • Provides status of production and disposition of work. Status information may include personnel, materials used, current production conditions. Includes recording of production information to allow forward and backward traceability. Criteria Positioning Simple Recipe & Tracking SAP Compliance/Traceability MES or xApp Performance Analysis • Provides real-time reporting of actual manufacturing operations results along with comparisons to past history and expected results. Performance results include resource utilization, resource availability, cycle time, conformance to schedule and standards. May include SPC / SQC analysis Criteria Positioning Simple Manual & Automated Systems SAP xMII Complex Recipes or Advanced Analysis MES + SAP XMII Operations & Detailed Scheduling • Provides sequencing based on priorities, attributes, characteristics and production rules. It is finite and it recognizes alternative and overlapping operations to calculate timing of equipment loading Criteria Positioning Simple Discrete Processing with a Large Supply Chain SAP APO PPDS Complex, Very Large, Non-linear Recipes SAP APO + MES or Consider xApp Document Control • Control records and forms that must be maintained with the production unit. Includes work instructions, recipes, drawings, standard operating procedures (SOP), batch records, shift to shift communication. It sends instructions down to operations and device controls Criteria Positioning Simple Work Flow SAP Simple WF and Regulatory Compliance SAP / Document Management System Complex WF with Regulatory Compliance SAP + MES+ Document Management Labor Management Provides status of personnel. Includes time and attendance, certification tracking, as well as preparation work as basis for activity–based costing. May interact with resource allocation for optimal assignments. Criteria Positioning Standard HR Functionality SAP HR Training Compliance during execution SAP/MES Maintenance Management • Functionality for maintaining equipment and tools. Ensures equipment and tools availability for manufacturing. May also include scheduling for periodic or preventive maintenance. Maintains history of past events to aid in diagnosing problems. Criteria Standard PM functionality Positioning SAP Plant Maintenance Real-time Condition Based SAP Plant Maintenance + MES Maintenance Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned SAP MES Architecture APO Demand Planning SNP PPDS Global ATP SAP R/3 BW Materials Management xMII Production Planning Quality Management Human Resources Integration Intelligence Dashboard Master & Transaction Data Plant Maintenance S95 xApps/Composite Apps MES OPC LIMS Historian PAT SCADA Devices Doc Mgmt Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned SAP MES Integration Options • Use SAP xMII – Preferred • Build your own XI integration SAP MES Integration Using xMII Manufacturing Intelligence Dashboards SAP BI Other SAP Bus. Solu tions Enterprise SAP NETWEAVER • SAP xMII enables real-time transactional integration between plant floor and enterprise (SAP ERP) systems out-of-the box thru: • Universal Connectivity to the data, functionality and processes of existing plant floor systems and SAP Advanced composite application capabilities for creating automated events, KPIs and alerts, and new manufacturing business processes Synchronization of SAP ERP with real-time Plant Floor Systems and Processes using proprietary and standards-compliant messages and workflows Data Services that provide a foundation for Manufacturing Synchronization and Intelligence • • SAP Manufacturing (mySAP ERP) • XI SAP xMII Manufacturing Intelligence Manufacturing Integration Plant Floor MES Integration with SAP – Using xMII PEOPLE SAP Enterprise Portal INFORMATION SAP R/3, SCM, BW… Integration SAP xMII B2MM L Msg Use xMII Integration capabilities if S95 Non Compliant Shopfloor Application – ANSI/ISA-95 Compliance = SAP = 3rd Party Application Agenda • • • • • • • Overview of MES Justifying MES Developing MES Strategy MES Architecture Integration Strategy Implementation Plan Lessons Learned MES Deployment Strategy • Understand the problem you are trying to solve • The business drivers • • • • How you deploy has impact on cost and scope Integration with Process Control and other applications Change in the business processes Facility readiness Analyze manufacturing processes and develop MES requirements Map requirements with SAP Functionality. Assessment Map MES Requirements Identify gaps Design MES Architecture Develop global processes, Integration touch points Detail plan for pilot and rollout Develop Deployment Plan Pilot Roll Out Review Pilot results Start Ramp-up Why Pilot? • Enhance understanding of MES • Determine how well current requirements fit into an MES • Validate the Integration strategy Scope of Pilot • Should cover end to end processes • Team • • • • • • Project Lead SAP Expertise – MM/PP/PI, QM, APO Automation Expertise QA/QC Integration/xMII Plant Floor • Timeline • About 3-4 months Take Aways • • • • There is an overlap of functionality offered by SAP and MES vendors • Perform detail MES requirement mapping with SAP functionality • Make the decision up front where the functionality resides (SAP or MES) • In many cases SAP + xMII + xApp could meet your requirements For complex processes, compliance and regulatory requirements, consider third party MES solutions xMII is the preferred Integration solution in the SAP landscape Start with an end to end pilot Session Code: 0707