Machining Brass, Copper and its Alloys

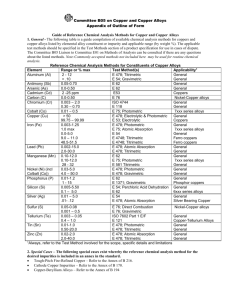

advertisement