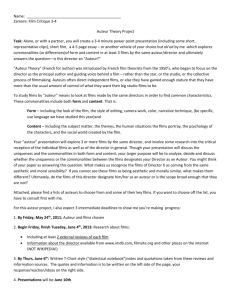

Fulltext - Infoscience

advertisement