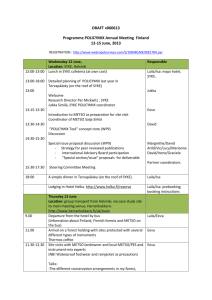

express

Fiber&Paper

Metso Paper news magazine dedicated to lifecycle support Issue No.3 2004

CTMP line and the

world’s first OptiStream

roll finishing line to be

supplied to Shandong

Huatai Paper in China.

Page

The new composite cover

CalTiger offers a new

dimension in cover selection

for demanding calendering

applications.

New active tools for high-speed

winding and a truly remarkable

12-second set change impressed

Francisco Carilla, Project

Director at SAICA.

4

Page

6

Page

SymBelt

M-real Kirkniemi places repeat orders for BowMaster

conventional curved spreader rolls

due to their insufficient spreading

efficiency. Wrinkles on sheet edge

areas were a particular problem.

In addition, conventional spreader

roll maintenance intervals are quite

short: on PM 3’s coater they were

less than 4 years due to the high operating speed. The maintenance of

conventional spreader rolls is fairly

expensive, too. However, one useful thing with conventional curved

spreader rolls is that in case of roll

failure, this kind of extensively

bowed roll can temporarily be used

as a non-rotating spreader bar,” explains Jari Tiura.

BowMaster, Metso’s state-of-theart paper spreader roll based on

advanced composite materials,

is still going strong. Fifty rolls

have now been sold worldwide,

and thirty of them are already

running. One of BowMaster’s

customers is M-real Kirkniemi

mill in southern Finland,

who use BowMaster rolls on

both their PM 1 and their

PM 3 off-machine coater.

Kirkniemi’s PM 1 runs at 13001340 m/min, producing 170,000 t/y

of ULWC coated wood containing

grade in the range 45-60 g/m2. The

PM 3 off-machine coater operates

at 1700-1750 m/min. The mill has

plans to increase the coater speed

to 2000 m/min within the next two

years. The PM 3 coater produces

350,000 t/y of coated special fine

paper in the 40-70 g/m2 range.

Jari Tiura, Mill Production

Manager, has experienced conventional curved spreader rolls in use

at the mill. “Every now and then

we had wrinkle problems with

two

2

CONTINUED ON PAGE 2

Condebelt containerboard grade for Asian markets

Kim Jin Doo, Mill Manager of

Dong Il Paper, South Korea.

Metso Paper and the Dong Il Paper

mill at Ansan city in South Korea are

striving to produce a new grade for

Asian containerboard markets. The

BM 1 at Dong Il is currently running

at 700m/min with a basis weight

range of 180-400g/m2. Metso Paper

has previously delivered a Condebelt

drying process, rebuilds for the wet

end and a production monitoring

system for the BM 1. The step-bystep improvement plan continues

with the press section rebuild and a

new size press after the Condebelt

drying process.

The SymBelt rebuild for BM 1’s

press section increases the board

dryness after the press, and also improves runnability and speed. The

production costs were lowered due

to the reduced steam consumption

in the drying section and also as a

result of the board being dryer after the press. “The SymBelt press is

technically and mechanically a very

good device,” states Kim Jin Doo,

the Mill Manager at the Dong Il

Dedicated to lifecycle support

8

Jari Tiura, Mill Production Manager,

(left) and Tommi Hevonoja,

Production Superintendent of PM 1,

from the Finnish Kirkniemi mill are

both satisfied with BowMaster’s

operation on their coater.

STEP-BY-STEP IMPROVEMENTS CREATE NEW

Paper mill. He also adds that “we

saved time by carefully planning

the installation and by making advance preparations for the start-up.”

The total shut-down time was just

twelve days and the machine was

running at normal speed and production again within 24 hours after

start-up. Kim Jin Doo reasons that

“the co-operation with Metso Paper

worked well since we have a good

relationship and deep understanding of each other”.

In addition to the SymBelt rebuild,

the machine is being supplied with a

size press in July 2004. This will secure the adhering of the glue between

different box layers as well as improve the surface quality of the board

with coating. Coating enables further

development of the new Condebelt

white top grades. The machine is

using Korean OCC as the primary

raw material with ash content often

exceeding 14%. The process is very

challenging but the customers are

satisfied with Dong Il Paper’s product.

“Our customers are impressed by the

board’s profiles, formation and even

quality,” Kim Jin Doo clarifies.

The mill is planning to further

develop the white top grades and

run the machine with modern

equipment to respond to the growing needs of containerboard markets in Asia. §

FOR MORE INFORMA T I O N

juha.a.leppanen@metso.com

Tel. +358 20 483 8845

Rebuild of KL 1000 control system

ensures trouble-free production

The rebuild of the KL 1000

winder control system at

Stora Enso Veitsiluoto has

substantially improved the

usability and reliability of

the mill’s PM 2. The rebuild

extends the lifecycle of the

winder and creates a solid

base for future upgrades of

other parts and functions.

The Stora Enso Veitsiluoto integrated

mill in Kemi, Finland is the world’s

northernmost paper mill, producing

865,000 tons of office and coated

mechanical paper per annum. The

6.5m wide PM 2 is one of four paper machines at the mill. PM 2 produces copy paper with a basis weight

of 80 g/m². The line is equipped

with one KL 1000 two-drum winder,

which was delivered by Metso Paper

(Valmet) in 1985.

S7 replaces S5 in

just four days

The delivery included a rebuild of the control and operating systems. Additionally,

the winder control room was

relocated and the winder was

equipped with monitoring

cameras. The original Siemens

S5 control system was replaced

with a Siemens S7 system during the rebuild that was carried out over four days in

8

the summer of 2003. According to

Aarne Suojärvi, Project Manager at

the Stora Enso Veitsiluoto mill, the

new control system has been functioning excellently ever since the

successful start-up.

two

2

CONTINUED ON PAGE 2

8

WindControl enables winder control

via a PC screen and keyboard or

from an operating panel at the winder.

Metso Paper has concentrated on

user-friendliness, an example

of which can be seen in the

use of symbols instead

of written text on

the keyboards

and panels.

THE HEART OF SHOE PRESSING

During the years, Metso Paper

has continuously improved

shoe press technology with a

view to further enhancing the

reliability and runnability of the

operation. Today the SymBelt

roll, the heart of the shoe press,

is more user-friendly than ever.

Metso Paper’s SymBelt roll: A

proven design with over 15 years of

experience. Continuous development

work has led to easier, faster and

even more reliable installation as

well as smoother belt operation.

SymBelt continues to improve

To meet customer demands, Metso

Paper has improved the belt clamping segments with new threads and

bolts and installation tools. This enables easy, fast and even more reliable installation as well as smooth

belt operation. In addition, the

new-design, belt-draping pipe with

reinforced brackets and screwed

connections facilitates better belt

installation and more reliable functioning.

One important development step

in the SymBelt’s operation is the

new doctoring solution, BeltDoc.

BeltDoc with a maintenance-free internal support shoe provides excellent and smooth belt doctoring results for different speeds and grades.

Furthermore, the SymBelt sealing has been developed to reach

the demands of higher speed machines. A new type of lip seal and

seal counter ring together ensure

reliable and long-standing sealing.

Toward smarter shoe pressing

Hydraulic belt stretching provides

even tension for the entire belt lifetime. The belt indexing does not

influence the belt tension and the

process is very reliable, thanks to a

longer support distance of moving

heads and sliding parts. New covers

for head sliding necks ensure reliable belt stretching and smooth head

operation.

Reduced hydraulic connections

and a multi coupling plate offer a

simplified and more compact design,

while the present one-zone loading

system with edge controls requires

no more than three hydraulic connections for nip loading. §

F O R M OR E IN F OR M A TI ON

jori.onnela@metso.com

Tel. +358 20 482 6168

express

one

1

CONTINUED FROM PAGE 1

dear

reader

Tissue production is fundamentally a sound and

excellent business that boasts particularly stable

global growth. Metso’s process delivery and

technology businesses currently produce some 40

percent of the world’s total tissue output. Metso’s

target is to maintain its position as the number one

supplier of equipment and services to tissue markets.

Metso Paper has actively launched its Process Services business for tissue customers. This business model serves Metso

Paper’s entire installed base. As is well known, Metso Paper

is the intellectual property owner of all Beloit delivered tissue

machines, and the Process Services business serves deliveries

under Metso’s former company banners including KMW and

Valmet, and now Metso.

The Process Services business provides installed base solutions ranging from simple replacement parts to technical

de-bottlenecking solutions to improve tissue makers’ productivity, quality, operational and energy costs. Metso’s technical

solutions are born from the combination of the world’s most

comprehensive library of machine data and technology together with supreme tissue technical expertise from Metso’s

employees. This wealth of knowledge and experience is further complemented by Metso Paper’s world-class tissue pilot

facility that provides tissue makers with a controlled full scale

testing ground for their new products.

Metso’s long and rich history dates back to 1891 with the

very first paper machine delivery. Our pioneering efforts have

continued through the centuries and decades resulting in innovations such as the current Thru-Air Drying technology.

Metso owns technologies that have been developed internally

through RTD efforts as well as acquired technologies such

as Beloit’s.

The latest examples of Metso’s creativity include the all

new, Advantage DCT100, Advantage Thru-Air 100 and

Advantage STT machines which cover the range of Dry Crepe

to Thru-Air dried production and incorporate the latest tissue-making features offered in the market today. Metso’s

Advantage Shoe Press also provides tissue makers with tissue quality advantages not available in conventional shoe

presses.

Metso Paper is committed to its customers with presence

around the world and offerings that provide tissue makers

with the highest competitive advantage in their business. /

8

Wrinkle free paper quality

provided by BowMaster on

the Kirkniemi PM 1 sizer.

To solve their spreading related

problems Kirkniemi decided to start

using new BowMaster roll technology for paper spreading.

Wrinkles removed

The first BowMaster roll at Kirkniemi

was taken into use on the PM 3 offmachine coater, positioned after the

1st sizer used for coating. The roll,

started in February 2003, operates

right after an infrared heater, where

high temperatures increase the demands set for roll reliability.

Jari Tiura mentions that in that

spreader roll position the mill used

to have continuous wrinkle problems which required constant adjusting. “The BowMaster roll has

reduced these problems remarkably,” he says.

one

1

CONTINUED FROM PAGE 1

8

Old control system problematic

The mill’s maintenance team initiated the project because spares for the

old control system were no longer

available. In addition, there had been

plenty of unplanned stops on the

winder caused by the outdated control system. By upgrading the control

system, the mill wanted to ensure a

trouble free winder operation.

Operators prefer WindControl

“Like in all other projects, the

Winder Operators were skeptical

about the rebuild in the beginning.

In a high-speed application such

as this, the BowMaster roll is dimensioned to operate on a speed

area above the roll’s first nominal

frequency. Kirkniemi find that when

the coater speed is accelerated over

this nominal frequency area a temporary rise in roll vibration level appears. This does not, however, cause

any problems for paper production.

“In fact,” says Jari Tiura, “after taking BowMaster in use, the coating

machine has been less sensitive to

start-up breaks.”

Excellent spreading effect

One year after the successful startup of BowMaster on the coater, Kirkniemi installed a second

BowMaster roll on their PM 1, in

a position before the second sizer

used for coating. The roll has now

run continuously for 8 months.

“On the PM 1 sizer we used to

have occasional wrinkle problems,”

comments Jari Tiura, “but these

have now been eliminated with the

BowMaster roll.” Tommi Hevonoja,

Production Superintendent of PM 1,

adds that the visual spreading result

is excellent, and sheet movement is

now more stable.

The rubber cover used on the

BowMaster roll in this application is cleaned with a wet sponge.

“Cleaning takes a bit more time, but

the cleaning intervals are about the

same as with conventional chromium coated curved spreader rolls,”

says Tommi Hevonoja.

However, the resistance remained

slight due to thorough training,

the user-friendly user interface and

the well-functioning control system” explains Suojärvi. “The operators quickly adopted the computer-based WindControl operating

system. They find that the control

panel’s illustrative symbols make

the system more user-friendly”.

Winder Operator Matti Kuoppala

is happy with the modern, easy to

use operating system that has become an essential tool in his work.

He particularly appreciates the feature that enables exact winding to

the accurate roll diameter or roll

length.

The latest BowMaster start-up

was also on PM 1, in a position before the reel. In the past, the mill

has had some problematic cases

of wrinkles at the reel. “After the

BowMaster start-up there hasn’t

been any indication of these problems,” Tommi Hevonoja explains.

Solution to demanding paper

spreading applications

Kirkniemi got BowMaster rolls to

improve operations in problematic

spreader roll positions. According

to Jari Tiura, BowMaster has fulfilled the mill’s expectations. The

roll spreading effect has been excellent. With just a couple of years running experience with BowMaster it

is still a bit early to evaluate roll

reliability, but so far the rolls have

been maintenance free.

After the successful start-up and

operation of these three BowMaster

rolls, Kirkniemi have now placed an

order for two more rolls. They are

happy to recommend Metso Paper’s

BowMaster to other papermakers,

too, as a solution to demanding paper spreading applications. §

FOR MORE INFORMATION

kari.roysko@metso.com

Tel. +358 40 839 8621

All goals accomplished

The rebuild of the KL 1000 control system improved the usability and reliability of the winder.

Furthermore, the WindControl

operating system significantly improved the winding reproducibility,

which is now in a totally different

class to the former manual operations. All goals for the rebuild set by

the mill have been fully met. §

FOR MORE INFORMATION

tommi.vuoristo@metso.com

Tel. +358 20 482 7297

The Winder Operator’s

desk before the rebuild.

The Winder Operator’s desk after

the rebuild. Matti Kuoppala, Winder

Operator at Stora Enso Veitsiluoto,

appreciates the WindControl

operating system’s numerous features.

New TMP line start-up for Stora Enso Varkaus

M ARCO MARCHEGGIANI

Fiber&Paper

President, Tissue Business Line

express

Fiber&Paper

Published by Metso Paper, Inc.

P.O. Box 587, FIN-40101 Jyväskylä, Finland

Tel. +358 20 482 150, Fax +358 20 482 151

In June, Stora Enso’s Varkaus

Newsprint Mill in Finland startedup a new TMP pulping line supplied

by Metso Paper. The design capacity of the TMP (thermomechanical

pulp) line is 600 tons per day, with

a maximum capacity of up to 700

tons per day. Metso Paper delivered

all of the main process technology

for chip washing, main line refining and screening, rejects thickening, refining and screening, steam

separation, heat recovery and post

refining.

Out with the old

and in with the new

The new TMP line is a complete

replacement for the former stone

groundwood pulp (SGW) plant.

“The take-over of the new line took

place exactly on schedule and we

were able to shut down the SGW

plant just two days later,” recalls Production Manager Matti

Leppänen from the Varkaus Mill.

The mill has two paper machines,

PM 2 and PM 4, for directory and

newsprint papers with an annual

Editor-in-Chief: Juha Kinnunen

Managing Editor: Riitta-Maija Peltovuori

Contributors: Björn Engström, Ulf Eriksson, Nathalie Faure,

Leena Färm, Eero Halmari, Björn Johansson, Anna-Riina Kirjavainen,

Anna Koskinen, Markku Käppi, Marika Lindeman, Jan Lindström,

Päivi Luoto, Kristiina Löfgren, Jari Marttinen, Elisangela Melo,

Vanda Molitor, Kirsi Mäntylä, Janne Märkälä, Heike Picker-Hess,

Riitta Pöntynen, Riitta Räisänen, Jori Sipari, Eric Tetreault, Susan

Trast, Alpo Tuomi, Martti Tyrväinen, Jorma Vänttinen, Stephanie

Wang, Tim Warriner.

English language editor: Bellcrest Language Services Oy

Lay-out and art work: Non-Stop Studiot Oy, Paul Hitchman

Printing: Libris Oy. Printed on Galerie One Silk 100 g/m2

production capacity of 280,000

tons. The new TMP line feeds both

of these paper machines.

The investment in Varkaus,

known as the Warma project, concentrated on enhancing paper quality by improving the products’ opacity and strength properties.

Good pulp quality

“The feedback from the paper machines has been very positive since

the beginning. The TMP pulp from

the new line has already proven its

ability to produce the desired paper

properties”, says Leppänen.

Wood handling modernized

The Warma project also included

the modernization of wood handling operations at the mill. Metso

Paper supplied a Camura GS chipper and a bark removal conveyor to

the wood handling line. The modernized line secures a constant chip

flow to the new TMP line. §

Published in September 2004

© Copyright Metso Paper, Inc.

All rights reserved.

Reproduction permitted quoting

“Fiber&Paper Express” as source.

2

Metso Paper news magazine

Production Manager Matti Leppänen and Supervisor Mauri

Mättö from the Varkaus Mill by an RGP main line refiner.

FOR MORE INFORMATION

mechanical.pulping@metso.com

OptiLoad TwinLine races to the market!

PILOT CALENDER AT COATING TECHNOLOGY

CENTER (CTC) ALREADY IN FULL OPERATION

The inauguration festivities of the

OptiLoad TwinLine calender and

Future Printing Center (FPC) included

the cutting of the ribbon: Manager

of CTC Päivi Miettinen in action.

OptiLoad multinip calendering represents Metso Paper’s leading calendering technology. This claim is

backed by the over 50 references

sold all over the world. Metso Paper

has recently introduced the latest

member to the OptiLoad family, the

OptiLoad TwinLine, to meet the demands of high speed calendering on

top quality printing papers.

Technology for high speed

and superior quality

The market is creating a demand for

faster and more efficient production

processes, in order to keep paper

mills profitable in an ever-tightening

competitive environment. For example, the new OptiLoad TwinLine

calender enables the cost efficient

upgrade of traditional newsprint

machines to high speed on-line SCproduction, the quality of which can

be optimized close to coated LWCpapers.

This new generation calender

can lend its superior calendering

capabilities to both uncoated and

coated printing papers. Besides

providing excellent tools for controlling two-sidedness and paper

profiles, OptiLoad TwinLine also

demonstrates outstanding operational flexibility.

Swing running modes allow the

papermaker to use all the nips in the

stacks or to select the nip arrangement best suited to the paper being produced. This allows the mill

to produce both matte and glossy

grades with the same calender.

For SC-paper applications, the

OptiLoad TwinLine dual stack configuration splits the calender into two

separate stacks and re-moisturizes

between them. This allows papermakers to keep moisture levels coming into the first stack low enough

to eliminate the risk of paper blackening and the loss of critical optical

properties, while ensuring required

end moisture levels even with high

thermo roll temperatures. On-line

moisturizing combined with high

calendering temperatures creates a

moisture gradient. This combination

results in paper surface properties

such as gloss, porosity and absorption that are far better than those

achievable with traditional multinip

calendering.

OptiLoad TwinLine at CTC

– a real multipurpose calender

The first OptiLoad TwinLine calender was inaugurated in mid January

of this year, at Coating Technology

Center CTC (owned by Ciba Specialty

Chemicals, Omya and Nordkalk), in

Raisio, Finland. According to Päivi

Miettinen, Manager of CTC, the pilot installation has drawn the attention of many customers interested to

learn the potential benefits OptiLoad

TwinLine can bring to their specific

grade. “Feedback from customers

has been very positive,” Miettinen

explains. “The new pilot calender

has been able to fulfill the research

needs of customers, from SC and

coated grades to even newsprint and

multi-ply board! Flexibility and versatility were among the key reasons

to invest in the OptiLoad TwinLine

pilot calender.”

Three new OptiLoad TwinLine

calenders will start-up next year

Metso Paper has already received

three other OptiLoad TwinLine

calender orders in addition to

CTC. The first production scale

OptiLoad TwinLine will start-up

next year. Two other OptiLoad

TwinLine calender start-ups are also

scheduled for next year, on the new

PM 12 at Stora Enso Kvarnsveden

mill in Sweden. This will be one of

the world’s largest paper machines,

and will produce top quality SC-paper. §

FOR MORE INFORM A T I O N

pekka.linnonmaa@metso.com

Tel. +358 40 594 1006

The OptiLoad TwinLine pilot

calender at the Coating Technology

Center (CTC) in Raisio, Finland.

Tissue Makers

meet at Metso Paper in Karlstad

Members of the European Tissue

Symposium (ETS), representing a

majority of tissue paper producers

throughout the EU, had its Spring

Meeting at Metso Paper in Karlstad,

Sweden between June 10 – 12.

Out of the world estimated annual tissue production of some 20 million tons, Western Europe produces

some 5 million tons of paper tissue

per year. The main grades are toilet

paper, kitchen towels and facial tissue, of which the ETS members are

the main producers. These products

have very special characteristics that

appeal directly to the consumers and

therefore create an especially close

relationship between the paper tissue manufacturers, their customers

and the consumers.

The Brussels-based trade organization serves its members by

providing quality guidance in these

relations and by preserving and defending this characteristic with public authorities.

Metso Papers Tissue Business in

Karlstad hosted the event and was

given the opportunity to present its

resources and also some local culture and entertainment. §

FOR MORE INFORMAT I O N

bjorn.engstrom@metso.com

Tel. +46 54 17 1203

Forming section improvements

for more profitable boardmaking

Two of the biggest challenges for

profitable boardmaking are continually higher customer expectations for end product quality, and

the special features of the various

board grades themselves. Increased

board machine speeds have also demanded better water handling for

the short circulation, and called for

improvements of web forming conditions. Metso Paper’s extensive

forming section product range offers customized solutions to accommodate the specific needs and wishes of every board manufacturer.

Customized forming

section solutions

Aside from traditional foil boxes

and vacuum boxes, Metso Paper’s

product line includes a highvacuum flat-cover HiVac suction

box for customers contemplating

quality, speed, production or maintenance upgrades. A movable forming board at the forming stage gives

a cost-effective way to improve formation.

In addition to traditional forming section operations and control

equipment, such as additional operator stations, breast roll lifting equipment, fabric replacement equipment

or stretchers and guides, Metso

Paper’s recent product development

work includes OptiCleaner Wet, a

forming fabric cleaner, WetMist, a

mist collector, and VacuDoc, a suction roll air doctor.

Optimization improves

boardmaking profitability

Web forming conditions at the forming section of a board machine have

a material impact on the structure

of the end product, particularly its

formation, which can only be greatly influenced at the forming stage.

Ideally, forming section production should be optimized with various forming section analyses, such

as runnability, production capacity, board quality, production safety

and cost analyses.

Stock that leaves the headbox in

a very turbulent and homogenous

state flocs up quickly in the forming

area as turbulence dies down. As

microturbulence of dewatering elements in the forming section loosens up the structure of the fiber web,

forming retention also decreases.

Formation-improving components

include various types of agitators,

such as a breast roll shaker, and different types of foil configurations.

Metso Paper’s FormMaster breast

roll shaker has a particularly favorable effect on formation.

Among other new products, the

MicroJet starch sprayer for increased plybond strength deserves

a mention. Another product to remember is forming board moving

mechanism, which allows for easier

adjustment of the slice jet impact

point. §

FOR MORE INFORMATION

kari.humalajoki@metso.com

Tel. +358 20 482 5992

Coating preparation capacity increased by 35% at

Stora Enso Grycksbo PM 10 – Metso PaperChem DryFeed

“The investment of DryFeed gives us

the edge for several years to come, both

quality and capacity wise.” says Tomas

Andersson, Superintendent of raw

materials from Stora Enso Grycksbo.

The Stora Enso Grycksbo mill is situated close to the city of Falun in the

Swedish Dalarna. Paper production

at the Grycksbo mill started in 1740;

today the mill produces wood free

and matt coated grades with three

machines. The Grycksbo PM 10 is

the newest machine, with a start-up

year of 1957. Over the years PM 10

has been rebuilt several times, the

latest rebuild was in 1999 when the

new coater was installed. At that time

Metso PaperChem was awarded the

contract to expand the coating color

kitchen originally delivered in 1987.

The mill has continuously optimized

the production process, and has further increased production capacity by

20% since the 1999 rebuild. A new

rebuild on the coating color kitchen

was inevitable in order to cope with

the increased coating color demand.

Metso PaperChem made a process study at the mill focusing on the

coating preparation capacity. The

conclusions made after the process

study were clear: the highest capacity increase would be achieved by

installing the new DryFeed process on the existing batch mixer.

The DryFeed process developed by

Metso PaperChem is specially designed for adding and pre-mixing

dry raw materials into the coating

mixer. Dry raw materials are typically used in order to achieve a higher dry solids content in the coating

color. The most commonly used dry

added chemical is CMC (Carboxyl

Methyl Cellulose). DryFeed solves

all the typical problems related to

the dry addition of components. It

enables good homogenity of the

additive flow, excellent pre-mixing

with no agglomerates, and most

importantly a significant capacity

increase.

The Stora Enso Grycksbo mill has

been using dry CMC since the previous rebuild in 1999. This meant that

the basic equipment needed for powder metering and pigment metering

was already available. Installation

of the DryFeed process was done

during a short maintenance break

on PM 10, the installation time was

roughly 10 hours. The time needed

for process optimization, i.e. setting

the right dosing speed for the CMC

and pigment, optimization of the

addition order and determination of

the coating color quality, was carried out the next day.

The main investment target was

to increase the coating color pro-

duction capacity. Another critical

issue is coating color quality i.e.

when the batch is ready virtually

no agglomerates are allowed in the

final color. The coating color quality after the DryFeed process was

installed was thoroughly checked

by measuring the screening residues,

viscosity and dry solids content of

the coating color.

The results of the process rebuild

were spectacular, coating color production capacity was increased by

35%, cutting the batch time from

75 minutes (before rebuild) to 55

minutes. The coating color quality was improved by decreasing the

number of agglomerates to zero and

decreasing the coating color temperature by 5 °C.

"We have never before been able

to achieve such a capacity increase

in any process with such a short

maintenance break. This investment

gives us the edge for several years

to come, both quality and capacity

wise. The whole DryFeed process

is easy to understand and the crew

at the coating kitchen have already

adopted the process. The commitment of Metso personnel to optimize

the process alongside the operators

was also of great importance," says

Tomas Andersson, Superintendent

of raw materials. §

FOR MORE INFORMATION

john.bergman@metso.com

Tel. +358 2048 24037

Wide range of automation and field solutions to

Stora Enso Kvarnsveden’s new world-class SC paper line

Metso Automation will supply Stora

Enso’s Kvarnsveden mill in Sweden

with a wide range of automation

and field solutions. This turnkey delivery is for a new production line

for high-quality SC paper being supplied by Metso Paper. With a capacity of 420,000 tons per year, the

new PM 12 line will be one of the

largest in the world. The start-up is

scheduled for the end of 2005. The

automation order is part of Metso

Paper’s total order that was an-

nounced on April 20, 2004.

Metso Automation’s delivery includes a full range of automation

solutions for the paper machine and

for two off-line twinline calenders.

These solutions include a metsoDNA machine control and a process

control system with process historian, a PaperIQ quality control system, profiling actuators, a Sensodec

6S condition and runnability monitoring system, a DNAforesight web

runnability monitoring camera

system, and a CCRV monitoring

camera system. Metso Automation

is also delivering Kajaani analyzers

and complete field instrumentation,

including amongst other things

Neles valves. All the systems are delivered on a turnkey basis including

engineering, installation, start-up

services and training. §

FOR MORE INFORMATION

matti.tapio@metso.com

Tel. +358 20 483 8040

3

Shandong Huatai Paper selects Metso Paper’s CTMP and roll finishing lines

Metso Paper will supply a

new CTMP line, a complete

bale pulping line and an

OptiStream roll finishing line

to the Shandong Huatai Paper

Co., Ltd mill in Dong Ying City,

Shandong Province, China.

The lines are scheduled to

start-up in December 2005.

CTMP line for mechanical

pulp production

The CTMP line will manufacture

high-quality BCTMP pulp (bleached

chemi-thermomechanical pulp) for

standard newsprint, high brightness

newsprint and LWC paper production. Chinese Poplar will be used as

raw material for the line.

The CTMP line is based on

Metso Paper’s proven high-capacity CD-refiner concept. The line will

include all of the core process technology required for chip washing,

main-line refining and screening,

reject refining, pulp washing, highconsistency bleaching and steam

separation.

Proven process for

high-yield pulping

Vice President Tian Zhiding explains that Shandong Huatai selected Metso Paper’s CTMP process on

the grounds of high reliability, advanced technology and easy operation. “CTMP is a globally proven

process for high-yield mechanical

pulping, and there are many successful CTMP references in operation. The large operating window of

the CTMP process gives us operational freedom. The process meets

our targets in producing hardwood

BCTMP pulp for high quality newsprint and LWC. The large conical

CD refiner in the main line can effectively guarantee sufficient energy input to improve the pulp qual-

ity. The high consistency bleaching

technology in combination with efficient pulp washing will ensure efficient bleaching, and save the consumption of chemicals.”

Higher quality at lower cost

“The CTMP process combines improved paper properties with a lower production cost,” continues Tian.

“We are targeting maximum bulk

and opacity at brightness levels of

up to 82 % ISO and freeness levels

below 150 ml CSF. Using high bulk

BCTMP in the furnish improves the

formation, bulk, surface smoothness and opacity of the finished paper. The lower production cost is

obtained by the very high bulk and

high yield of the BCTMP compared

to chemical pulp.”

Metso Paper has received

three CTMP line orders from the

Shandong Province within the past

12 months. §

FOR FURTHER INFORMATION

hakan.dahlin@metso.com

Tel. +46 60 16 54 07

Europe

The CTMP line delivery contract

was confirmed by (left to right)

President Li Jianhua of Shandong

Huatai and Vice President, Sales,

Håkan Dahlin of Metso Paper.

The Huatai mill is situated in Dong

Ying City, Shandong Province, in the

lower reaches of the Yellow River

and the eastern region of the North

China Plains. The Huatai Group is a

publicly listed large-scale company

comprised of paper mills, chemical

industry facilities, printing houses,

thermoelectricity power plants, tree

plantations, and trade and service

industries. The company has several

paper machines and produces newsprint, fine paper, special printing papers, coated board and tissue. The

Huatai Group is the biggest newsprint producer in China, producing

some 800,000 tons of various mechanical papers per annum.

OptiStream roll finishing line

The world’s first OptiStream

roll finishing line will be

supplied to the new PM 11

newsprint machine. Shandong

Huatai Paper selected Metso

Paper following the successful

delivery of a winder and roll

wrapping and handling systems

in 2001 for the mill’s PM 9.

Continuous production flow

OptiStream integrates finishing operations and information management into one seamless entity and

ensures a continuous flow of production and information. The extensive scope of Metso Paper’s

OptiStream delivery includes two

WinBelt winders with automated

transfer rails and a core handling

system, an OptiCart parent reel

cart, a StreamLine wrapping machine and roll handling system. The

processing, recording and reporting

of shipping roll data is performed exclusively by the Metso RollControl

system. The finishing room layout

has been jointly designed by Metso

Paper and the mill.

A convincing solution

Sun Changgeng, Vice General

Manager of Pulp and Paper Company

Huatai Group, believes that sourcing all of the finishing equipment

from one supplier is highly beneficial. Metso’s machines are not only

well engineered and reliable, the

OptiStream solution links together

the highly automated machines and

assures that all segments of the roll

finishing system combine seamlessly,

ensuring efficient paper production

right from the start-up.

Highly automated

WinBelt winders

The trim width of the highly automated WinBelt winders is 9.8 meters. The winders are equipped with

automatic set change, automatic

slitter positioning and automated

core handling and gluing. Metso’s

delivery also includes automated

parent reel transfer rails from the

paper machine to the winder.

The decision to purchase WinBelt

winders was based on the positive

results from the WinDrum winder at

the mill’s PM 9. According to Wang

Chunran, Project Engineer of finishing operations, the runnability of the

WinDrum is excellent. He is pleased

that Metso Paper will deliver the

winders and roll wrapping and handling system for the new line.

Pulp drying line

to Ripasa, Brazil

High capacity StreamLine

wrapping machine

The roll wrapping and handling systems are designed for a capacity of

160 rolls/hour. The fully automatic

StreamLine multistation wrapping

machine is equipped with four industrial robots and overlap wrapping. StreamLine can be controlled

by a single operator, who monitors

production flow and handles material replenishment.

The cornerstone for an optimally

functioning finishing line lies in

a well-designed, efficient layout.

Metso Paper is able to provide mills

with invaluable layout expertise.

FOR FURTHER INFORMATION

ilkka.tuomenoksa@metso.com

Tel. +358 40 528 0779

Kappa Kraftliner Piteå mill gearing up

to growing demand for white top linerboard

Kappa Kraftliner Piteå is the biggest

kraftliner mill in Europe, producing

640,000 tons a year of various linerboards. They have five different

corrugated material qualities from

brown liner to white top liner, including mottled liner and high quality coated linerboard, all under the

same Royal Kraftliner brand. PM 1

produces brown kraftliner and PM 2

is dedicated to the increasing production of white top liner. A major

proportion of the production goes

to customers in Europe.

Anneli Burman and Lars Bergström

are satisfied with the last two years’

co-operation between Metso Paper

and Kappa Kraftliner Piteå.

4

Metso Paper news magazine

The demand for white top linerboard has increased in recent years

and the market for white top applications is growing faster than for

brown. This is due to the market

trend for more promotional packaging and high quality printing in corrugated board. Kappa Kraftliner Piteå

mill has prepared for the growing

demand for white top liner with continuous investments and co-operation with Metso Paper for their PM 1

and PM 2 in the last two years.

The biggest recent investment in

PM 1 was carried out in 2002 for

increased production and drying

capacity. At the same time as the

rebuild of PM 1, PM 2 had a quality targeted rebuild. Both rebuilds

were end results of a machine analysis done by Metso Paper in 2001.

“The scope of the rebuilds was well

optimized after the machine analysis,” points out Lars Bergström,

Superintendent of PM 2. The production of both machines has now

been successfully increased and optimized for linerboard markets.

Metso Paper was selected as the

machine supplier for both rebuilds

after the analysis, thanks to the

unique headbox technology, good

co-operation, and excellent references from Munksund mill. PM 2 was

supplied with a new dilution headbox and wire section reconstruction. “The profiles of PM 2 were

significantly improved with the new

headbox,” says Bergström. “We

achieved the quality targets straight

after start up, so I am very pleased

with Metso Paper’s work.” Due to

some other small investments PM 2

is now also more efficient. PM 2 is

running with half reduced breaks,

mainly thanks to Metso Paper’s

well functioning transfer box in the

top wire.

For PM 1 the target was to increase the production capacity by

removing the machine’s runnability and drying capacity bottlenecks.

“Together with Metso Paper we chose

the optimal rebuild solution for

9% drying capacity increase,” says

Anneli Burman, Superintendent

of PM 1. Runnability issues were

solved with small but essential slalom group modernizations for the

first drying section, runnability blow

Kappa Kraftliner Piteå is located

in the north of Sweden. It is the

biggest kraftliner mill in Europe with

640 000 tons annual production.

Metso Paper will supply Ripasa

S/A Celulose E Papel in Brazil with

a complete pulp drying line for its

Limeria mill in the state of Sao Paulo.

The pulp drying line delivery will include bleached stock screening and

wet end, airborne dryer, cutter-layboy and pulp baling systems. The

drying line is dimensioned for a 760

adt a day capacity, and has a trim

width of 3,9 m and a design speed

of 200 m/min. The line is furnished

with combi and shoe presses for optimum dryness prior to the airborne

dryer. In addition, Metso Paper will

also provide training, erection- and

start-up supervision services.

The new drying line is scheduled

to start up mid 2005.

In recent years Metso Paper has

received several corresponding complete pulp drying and baling system

orders. The drying line at VCP

Jacarei mill in Brazil was started up

late 2002, Arauco Valdivia line in

Chile early this year, and the most

recent start up was at Stendal mill

in Germany this summer. §

FOR MORE INFORMATION

jukka.sampi@metso.com

Tel. +358 400 590 968

Pulp drying line at Arauco Valdivia in Chile.

boxes, and ropeless tail threading

before the second drying group. In

addition a pope pulper was added

to handle the increased production.

Overall the cooperation between

Kappa Kraftliner Piteå and Metso

Paper has been working well in recent years. “People are always easy

available, the technological solutions for the board machines are

innovative, and Metso Paper works

flexibly,” states Bergström. §

FOR MORE INFORMATION

goran.tranberg@metso.com

Tel. +46 54 17 1461

Strengthening cooperation between

paper makers and machine suppliers

Europe is a traditional and very important market for Metso Paper’s pulp and paper machinery services and rebuilds. Such services are necessary to maintain and

improve the performance of existing installations. Incorporating these services into

the purchase contract for a new line creates a solid foundation for cooperation

with the machine supplier throughout the production line’s lifecycle. Particularly in

European paper mills, the trend is moving towards stronger cooperation between

paper makers and machine suppliers. Our customers want to concentrate on their

own core business - paper making - and are willing to outsource the maintenance

work of their production lines to service specialists such as Metso Paper. This level

of cooperation demands mutual commitment and deep trust, and can only be successful if it proves to be beneficial for both parties.

Metso Paper is usually recognized as a supplier of state-of-the-art high-speed

paper and board machines. We are proud of this reputation and maintain our

position in this very challenging market by means of constant development and increasing effort. Because of our status, it is easy to assume that Metso Paper is simply a service supplier for large and high-speed machines, but this is not the case.

Most of our services and products are suitable for all production lines, regardless of the speed or width of the machine. In order to stay competitive in the

future, we must develop specialized products and services for paper, board and

tissue machines. The market will call for more and more products and services

for big machine lines and smaller machines alike. Our target is to not only hold

a strong position in terms of our own installed base, but to also be a preferred

service supplier for other paper and board customers too, irrespective of who

originally delivered the machine.

The key elements in a successful partnership are availability, fast response,

reliability, professionalism and open communication. How can Metso Paper develop these characteristics to be even better in the future? We have to train and

educate our people continuously as we are doing today, but the most effective

way is to listen to our customers and to learn from them. Both positive and

negative feedback is the only way to develop our way of working to match our

customers’ needs, and we now challenge you to provide this kind of feedback.

We hope that this new issue of Fiber&Paper Express will bring our new

thoughts and ideas on service and rebuilds to your attention! /

Senior Vice President, Process Services, Paper Business Line

jari.vahapesola@metso.com

Tel. +358 20 482 5260

New Service Center strengthens

Metso Paper’s Korean presence

Dedicated to lifecycle support

“UPM-Kymmene Shotton mill

in the UK rebuilt the machine

calenders on its PM 1 (2003)

and PM 2 (2002) because of

a planned increase in the

amount of deinked pulp (DIP)

in the base paper. Shotton

increased DIP production

capacity in 2003 and at the

same time started producing

newsprint from 100 % recycled

fiber (earlier ~60 %),” explains

Timo Heinonen, operations

director at Shotton.

“Rebuilding the Shotton PM 1 and

PM 2 machine calenders was a good

decision,” says Timo Heinonen

(left), operations director at UPMKymmene Shotton. Next to Heinonen

is Graham Sutton, Managing Director

at Metso Paper Limited in UK.

J A R I V Ä H Ä P E SOLA

Metso Paper has expanded its aftermarket operations in Korea by establishing a new Service Center in

Daejeon, about 150 km south of

Seoul. The new center is centrally

located with regard to the country’s

pulp and paper industry.

The Daejeon Service Center provides the Korean pulp, paper, board

and tissue industry with traditional

spare parts service as well as roll

service and maintenance.

The development of the local aftermarket operations demonstrates

Metso Paper’s commitment to lifecycle support.

In his speech at the opening

ceremony of the Service Center,

Kim Luotonen, the Ambassador

of Finland in Korea, pointed out

Metso Corporation’s standing as an

all encompassing service house for

the global paper and pulp industry.

In today’s world, where meeting

deadlines is of paramount importance, Metso’s clients can benefit

from procuring entire integrated

processes from one supplier.

Metso Paper’s Area President

for the Asia-Pacific region, Kaj

Lindroos, remarked in his speech

that Metso Paper undergoes constant modernization in order to

serve its customers better. One example of this is the increased focus

on geographical area management.

The Daejeon Service Center will

strengthen Metso Paper’s local pres-

Machine calenders on newsprint lines PM 1 and PM 2

in Shotton were rebuilt to meet the requirements of DIP

The current trend in newsprint production is to use as much recycled

fiber as possible. Since recycled fiber

has gone through several production processes in its lifetime the fiber

is easily moldable and easy to calender. This is where traditional machine calenders in newsprint mills

become hard to control.

Standard DIP based newsprint

requires mild calendering with low

linear loads, which is not easy to

handle with traditional 4 to 6-roll

machine calender stacks. “The dead

weight of the rolls adds up to calendering loads which are too heavy,

and the sheet gets too smooth,”

explains Timo Heinonen. “The

Shotton 4-roll stacks were rebuilt

by reducing the roll amount to two,

making a single nip formed by two

deflection compensated SYM-rolls.

The new configuration with reduced

roll amount has enabled the minimum loading to be decreased to a

level better suited for DIP newsprint.”

The former pneumatic loading

systems were replaced with more

precise hydraulics. All calender

rolls were overhauled and modified

for double oil circulation, which

had a beneficial influence on rolls’

temperature profiles. The rebuilds

included some changes to the hydraulic systems as well as the installation of new doctors to insure the

cleanliness of the roll surfaces. The

Metso is no stranger to

the Korean market

Metso Paper supplied the first paper

machines to Korea in the 1980s. In

all, Metso has made approximately thirty major machine deliveries

to the country. Machines manufactured by Metso Paper produce

about one fourth of the paper and

board in South Korea. §

FOR MORE INFORMATION

harri.haavisto@metso.com

Tel. +358 40 596 4700

Ropeless tail threading with SingleForce Plus

ence and improve its capability to

serve the Korean paper industry.

A seminar for Korean paper

making professionals

Before the grand opening, there

was a half-day seminar in which

Ari Leppänen, Area Vice President,

Paper Business Line, gave a presentation on the shoe press in the 3rd

press position.

Kyoung-seop

Kim,

Metso

Paper Korea’s Product Manager,

talked about the advantages of the

BowMaster roll for web spreading

and also spoke about mechanical roll

maintenance products. Ari Telama,

Area Vice President, Process Services,

explained the benefits of co-operation agreements and maintenance

outsourcing.

controls on PM 1 were upgraded

to metsoDNA to meet the requirements of the new loading system.

The calender rebuilds were implemented in two separate phases

in 2002 and 2003 before the 100%

DIP process was started at the end

of 2003. The modified calender

configuration also worked well in

the period before the 100% DIP

process. “We carried out some pilot trials at the Metso Technology

Center in Järvenpää before the rebuilds, in order to define the right

calender configuration. Rebuilding

the existing machine calenders was

a good decision. We have reached

the desired quality and the results

have met our expectations,” says a

satisfied Timo Heinonen.

Metso Paper has rebuilt a large

number of machine calenders with

somewhat varying scopes depending on the targets. The need for a

rebuild may arise from a change in

paper grade or furnish, vibration

problems, change in production

speed, etc. §

SingleForce Plus compensates for the forces affecting

the tail particularly in the opening nip area.

Constantly increasing paper machine speeds and safety regulations

set further demands on tail threading. With this in mind, Metso Paper

has developed a new solution to

boost the tail threading process:

SingleForce Plus provides more reliable ropeless tail threading for single-felted dryer groups.

Well-managed tail threading

SingleForce Plus operates as a tail

threading zone vacuum booster for

single-felted dryer groups. It operates together with SingleForce, a

compressed air operated tail threading system, where vacuum is created with the help of blow boxes and

VacRolls or TailVac rolls SingleForce

Plus is applicable with SymRun HS

blow boxes.

Forces affecting the tail in singlefelting can complicate the threading

process, especially in the opening

nip area. The high vacuum zone

created by SingleForce Plus compensates for these forces and thus

prevents the tail following the dryer

cylinder surface.

SingleForce Plus provides improved machine line efficiency

by increasing the threading process reliability even with varying

speed, basis weight, moisture or

dryer cylinder temperatures. As a

compressed air operated system,

SingleForce Plus requires less maintenance, spares and wearing parts,

making the threading process more

economical. §

FOR MORE INFORMATION

kari-matti.laitinen@metso.com

Tel. +358 20 482 5907

VERACEL PULP MILL PROJECT INCLUDES SIGNIFICANT AMOUNT OF

Neles valves and Kajaani analyzers

FOR MORE INFORM A T I O N

esa.karki@metso.com

Tel. +82 11 359 7038

The ribbon cutting in the

opening ceremony.

Metso Automation will deliver

Neles valves and Kajaani analyzers

worth over six million euros to the

Veracel pulp mill project in Brazil.

The start-up of the mill is scheduled

for mid 2005.

Metso Automation provides the

mill with more than a thousand

automated Neles valves - on a complete fiber line and white liquor

plant by Andriz, a boiler plant by

Kvaerner, evaporators by Confab

and on a water treatment process

by Centroprojekt. Over 600 critical flow control applications are

furnished with Metso Automation’s

latest digital valve controller technology ND9000 and Hart communications.

The Kajaani analyzers will be

included in the controls of the fiber

line and white liquor plant. The

fiber line delivery includes kajaaniKAPPAi and BRITEi analyzers for

delignification and brightness control. Several kajaaniPOLAROXi

residual sensors, kajaaniCORMECi

and pH measurements with kajaaniFiltratePistons are also included to

provide measurements for bleaching

line standard controls. In the white

liquor plant, the automatic process

titrator kajaaniALKALi will handle the critical liquor analyses for

causticizing process monitoring and

control. The chosen technology is

specially designed for the production of high quality pulp with minimum environmental impact.

With a designed annual capacity

of 900,000 tons of bleached softwood market pulp, Veracel’s greenfield pulp mill will be the largest in

the world.

Veracel Celulose S/A is a joint

venture of Aracruz Cellulose S/A,

the world-leading producer of short

fiber eucalyptus pulp, and Stora

Enso, the second largest paper producer in the world. §

FOR MORE INFORMATION

marcelo.motti@metso.com

Tel. +55 15 219 1300

ilpo.miettinen@metso.com

Tel. +358 20 483 160

janne.tolonen@metso.com

Tel. +358 20 483 121

5

paper

extreme

A SPOT OF LIGHT READING?

World’s largest published book weighs 60 kg

The world’s largest book was published in December 2003, when author

Michael Hawley, a scientist at the Massachusetts Institute of Technology

(MIT), revealed his monumental book “Bhutan: A Visual Odyssey Across

the Kingdom”. The tome has 112 pages, measures 1.5 by 2.1 meters (5 by

7 feet) and weighs 60 kg (133 pounds). For each copy, a full U.S. gallon

(3.8 liters) of ink is used.

Hawley did not set out with the intention to produce the world’s largest book. However, while working at MIT’s Media Lab with a specialist

digital printer, he discovered the spectacular quality of large digital images.

His first idea was to create a 5-by-7-foot wall that would enable the owner

to change the picture every day. But then he realized there was an old-fashioned mechanism that might work - a book. The result is a showcase of a

variety of new digital, photographic and printing techniques.

Image processing and printing for the book demanded considerable

computing power. Each page image is close to two gigabytes in size, pushing the envelope of computer and printer capacity. Each copy requires 24

hours of printing time.

The book’s assembly posed its own problems. Traditional bookbinding

methods are inappropriate for a book of this size so a special binding machine combining western and oriental bookbinding techniques was created.

Each copy of “Bhutan: A Visual Odyssey Across the Kingdom” costs

approximately USD 2,000 to produce. Five hundred limited edition copies

are being produced, but the book is not being sold in a traditional way. It

is offered to people who make a donation of at least USD 10,000 to a nonprofit educational charity. Proceeds will benefit Bhutanese schools, scholars

and educational programs. Each copy will be built expressly for the recipient. The book is supplied complete with an easel-like display stand. §

Forming section performance optimization

The forming section is one of the

most important and complicated

parts of a board machine. It produces

the basic structure of board plies,

combines them with one another,

and removes more than 90% of the

web’s water content. Reliable forming section operation is a prerequisite for the efficient manufacture of

quality products; it thus also plays

a role in determining the financial

performance of a mill.

Metso Paper offers a broad selection of products that can assist

in the maintenance, testing, tuning,

development, upgrading, servicing, learning, and optimization of

a board machine’s forming components and process. All of these products can be further customized and

combined into very comprehensive

cooperative service packages for the

board machine forming section.

This cooperation can entail the

continuous contractual optimization and development of the customer’s process and related costs,

or it can also be based on ad hoc

problem solving, condition testing

or investment-specific assistance.

Each customer can freely choose

the level of partnership with Metso

Paper that best suits their needs.

Tests and analyses

Metso Paper’s basic tools for investigating the condition and operation

of a forming section consist of various tests and analyses. They help

customers reduce their operational

risks, lower shutdown and operating

costs, and improve efficiency. They

also provide useful background in-

formation for possible quality, speed

or volume upgrade projects.

Examples of Metso Paper’s

tests and analyses for

the forming section

Process-oriented tests and analyses

Runnability study

Efficiency audit

Stock and board sample analyses

Process analyses

Wet end chemistry audit

Tail threading audit

Slice jet speed profile measurement

IR camera analysis

Doctoring study

Ventilation audit

Automation-oriented

tests and analyses

Guide and stretcher test

Machine automation audit

Process automation audit

Steam box study

Break automation audit

Mechanically-oriented

tests and analyses

Alignment checks

Roll audit

Suction roll crack inspection

Corrosion study

Vibration study

Foundation plate leveling

measurements

Mechanical drive condition

measurements

Ceramics audit

Other tests and analyses

Lubrication study

Washing/cleaning study (shower

and cleaning analysis)

Reliability (applied RCM) analysis

Maintenance audit

Shutdown audit

Optimization

The forming section can

be optimized with respect

to aspects such as:

◗ runnability: breaks/

profiles/cleanliness

◗ production capacity:

maximum gross production

◗ board quality: formation, profiles

◗ safety: operator safety, risks

◗ costs: maintenance/operating

costs/raw materials/energy

◗ environment: water

consumption, noise, smell

◗ shutdown control: planned/

unplanned shutdowns

Metso Paper and its network of

cooperative partners can provide

experienced technical experts and

tested tools and methods for all of

the above, including laboratory facilities and pilot machines. §

FOR MORE INFORMATION

ari.hiltunen@metso.com

Tel. +358 20 482 5212

The optimization of a forming

section can proceed in steps.

Successful GradeMatic start-up at

Felix Schoeller in Titisee-Neustadt

Metso PaperChem has supplied a chemical management system

to the Felix Schoeller Group in Neustadt, Germany, consisting

of an unloading station for chemicals, chemical storage, a

GradeMatic unit and a supply system for the size-press.

The new surface size preparation

system was a part of rebuild of the

PM 18 making it possible to produce new grades at the machine.

The surface size used at Felix

Schoeller is very expensive and chemical losses are also difficult to manage, therefore Felix Schoeller decided to invest in a continuous surface

size preparation system with small

volumes. The surface size is also

quite complicated to prepare and

therefore a trial run was conducted

in Raisio at Metso PaperChem’s pilot-plant. GradeMatic facilitates the

possiblity of altering the component

dosing order, which is not typical

with continuous coating color preparation. Overall, the trial proved to

be very successful and convinced

the project team that the right process solutions had been made.

Entrained air in surface size has a

negative impact on the final product

quality. With GradeMatic, coating

color is prepared in a closed pressurized process, meaning that no air

is mixed into the product. This was

one of the GradeMatic unit’s most

important features as far as Felix

Schoeller was concerned.

In accordance with the millstandard, the whole delivery was

automated with the Siemens PCS7.

The size kitchen delivery also comprised a recipe handling system.

The available space for the supply system and size kitchen was

very restricted, and the installation

had to be completed in limited time.

GradeMatic is a small and compact

unit and is delivered as a pre-installed

unit. This together with sound preengineering made it possible to reduce the required work on site.

According to Michael Haffke,

who was the Project Manager,

Technology, during the delivery and is

currently the Factory Manager of the

Technocell Mill, Osnabrück, the Felix

Schoeller project production team is

very satisfied with the results of the

project. The co-operation with Metso

PaperChem worked well right from

the very beginning through to the installation, start-up and training. §

With GradeMatic, coating color is

prepared in a closed pressurized

process, meaning that no air

is mixed into the product.

mikael.furu@metso.com

Tel. +358 2048 24010

6

Metso Paper news magazine

FOR MORE INFORMATION

SAICA orders

WinDrum Pro

from Metso Paper

S.A. Industrias Celulosa Aragonesa

(SAICA) has placed an order with

Metso Paper for a high capacity WinDrum Pro winder. The

WinDrum Pro winder will be delivered to the SAICA mill located

in Zaragoza, Spain for use on their

corrugating medium and testliner

machine. Start-up of the winder is

scheduled for December 2005.

The highly automated WinDrum

Pro winder has a trim width of 7.8

meters and its operating speed is

2500 m/min. The winder is equipped

with automatic set change, automatic slitter positioning, automated

core handling and gluing and automated parent reel transfer rails from

the paper machine to the winder.

The winder’s capacity is further

increased by Metso’s Continuous

Winding automated function package, which permits fully automatic

winding as long as there are new

parent reels available.

WinDrum Pro winders give paper mills the ability to meet industry

production demands by increasing

winder throughput. New active

tools for high-speed winding coupled with a truly remarkable 12-second set change can increase winder

capacity by up to 15%.

Leading technology

prompts selection

Metso Paper’s superior winding

technology convinced SAICA to

select WinDrum Pro. According to

Francisco Carilla, Project Director,

the high capacity of the winder, the high level of automation

which allows one-man winder operation, the fast set change and the

increased winding speed were all

important factors in their decision.

Equally important was the ability

to reduce vibration by adjusting the

gap between the front and the rear

drums.

“Metso Paper is one step ahead of

other suppliers in winding technology.”

Francisco Carilla, Project Director at

SAICA, explains the reasons for choosing

WinDrum Pro winding technology.

SAICA in brief

SAICA is one of the leading manufacturers of testliner in Europe, producing over 1.5 million tons per

year. The company has five mills

and seven paper machines located

throughout Spain and France. §

FOR MORE INFORMATION

tapani.nyman@metso.com

Tel. +358 20 482 7392

HOW A BOARD MACHINE ANALYSIS LED TO A MODERNIZATION PROJECT

− The rebuild of BM 7 at Oudegem

Papier in Belgium by Metso Paper

Oudegem Papier in the Belgian town

of Dendermonde produces fluting,

testliner, carton and core board on

their three board machines, with a

total annual production of approximately 350,000 tons. The No. 7

machine, supplied by Voith in 1996,

manufactures approx. 150,000 t/

year of fluting. The machine has a

maximum speed of 770 m/min and

a wire width of 5600 mm.

In November 2003 Oudegem

Papier ordered a comprehensive

machine analysis from Metso Paper.

In the analysis, bottlenecks were

determined in the areas of capacity,

runnability, maintenance and board

samples, as well as in the wire and

press sections, size press and reel.

The mill was very pleased with

the results of the analysis: bottlenecks were revealed in detail and

the extent of the planned modernization could therefore be fixed with

definite targets.

A machine analysis gives a sound

basis to optimize a rebuild. Among

other benefits it makes it possible to

determine to what extent existing

structures and other components

can be reused. The aim of the modernization in this case was to improve runnability, increase efficiency

and to upgrade product features.

In June 2004 Oudegem Papier

ordered the first part of the rebuild

of BM 7 from Metso Paper. The rebuild is planned in two stages. The

first stage in October 2004 will include a new mist collector, two new

trim suction boxes, the rebuild of

the press section with transfer suction boxes and press nip blow boxes, new spray pipes after the second

press, and a TailJet water cutter

after the dryer section. The second

stage in December 2004 will comprise a new pick-up roll with spare

shell, save-all, doctor and modification of suction box of transfer suction roll. §

FOR MORE INFORM A T I O N

two are from 1969 and one from

1974. Two of the presses have already been fitted with new feed

motors and one has the new valve

block. The third press will change

feeding motors and new valve

blocks will replace the old camshaft

operating unit on the other two.

This upgrade will increase capacity by 10-15% and, as in Vallvik,

maintenance will be made easier.

The Rottneros mill produces both

ground wood pulp and CTMP and

is one of the world-leading producers

in these two categories, due largely to

the fact that the mill can deliver tailor-made pulp quality according to

customer requirements.

Supervision is included in the deliveries at Vallvik and Rottneros. §

FOR MORE INFORM A T I O N

marika.levander@metso.com

+46 60 16 58 12

board machine fourdrinier on the

front and back side in a location

where the web has drained enough

for the trim to be blown off from

the surface of the fabric.

Metso Paper’s new trim collecting

system, TrimRecovery, has been

designed for the efficient and costeffective recovery of trim that can

be reused as fiber raw material for

multiply board machines.

TrimRecovery allows for the

controlled recovery of the most

expensive top-quality trim of the

fiber raw material so that it can be

reused. The system effectively prevents the trim from being mixed

with the stock system. The trim

collecting system is installed at the

Dedicated to lifecycle support

Patent pending

The new trim collecting system

consists of a trim squirt, a blowoff blow nozzle and a trim collector. The trim squirt cuts the trim

reliably and neatly. The trim, having been cut with the blow-off blow,

is directed from the surface of the

fabric to the trim collector. Metso

Paper has applied for a patent on

the TrimRecovery system.

Due to substantial savings in raw

materials and low running costs, the

typical payback time for the investment in TrimRecovery is about four

months. §

Water buffer volume bigger than stock volume

require additional water treatment.

Net production efficiency in

closed paper mills without effective

water management could be noticeably lower than in similar mills with

an open water system. In such cases,

water management solutions could

normally increase the runnability to

an acceptable level.

At mills with high or normal fresh

water consumption levels, good efficiency can normally be achieved

without any additional kidneys.

Internal kidneys are only necessary

if runnability is expected to be low.

When reaching low or extremely

low fresh water consumption levels, ultrafiltration is required and

additional purification to improve

the runnability is carried out with

microflotation.

If salt removal efficiency is the

key issue, part of the permeate originating from ultrafiltration plant can

still by treated with nanofiltration.

Ultrafiltration technology has

great potential in helping to improve paper machine runnability

and to decrease the fresh water consumption. The aerobic bioreactor

system seems to be already accepted

as a standard solution for the new

European paper mill effluent treatment plants.

By combining state-of-the-art

technologies and solutions in the

right way, water consumption and

the environmental load of paper mills

can be significantly reduced. §

Careful steps lead to effective water management. Metso Paper

has invested heavily in the development of water management

solutions for pulp and paper making processes.

paperchem.info@metso.com

Recommended actions

20 m3/t

10 m3/t

keijo.ruonala@metso.com

Tel. +49 6157 9455 0

TrimRecovery system

offers substantial savings

TrimRecovery system cleans

trim area effectively.

Effective closure of the mill’s water

system requires new thinking, combining the pulping department, paper machine and effluent treatment

operations. The best solutions need

a mill-wide technical and economic approach. Although savings or

losses due to runnability and product quality are much more critical

for mill profitability than the water

treatment costs, it should be borne

in mind that well-organised water

management can provide the possibility to turn water costs into savings.

The traditional approach to

waste water treatment in European

mills has been to collect all process

waters in one central effluent treatment system and then recycle the

cleaned water back into the process. The new method calls for sepa-

15 m3/t

Vallvik and Rottneros upgrades

to increase baling line capacity

When the fiber line at Vallvik Bruk

AB in Sweden increased its capacity, the old PFC-type slab presses

installed for flash dryed pulp a bottleneck. Now the two PFC-presses

from 1974 and 1980 will be upgraded to handle today’s high production levels.

The upgrading consists of valve

blocks, press forms and feeding

motors. Capacity is expected to increase by 10-15% and maintenance

will be made much easier with

the introduction of the new valve

blocks.

The Vallvik mill produces chemical pulp and its output consists of

three types of bleached, long-fiber

sulphate pulp: elemental chlorine free, totally chlorine free and

unbleached kraft pulp. The production capacity at Vallvik is 190,000

tons per year.

Rottneros mill in Sweden has

four PFC-presses, one of which, no

longer in operation, is the original

prototype delivered by Sunds AB in

1967. Of the three running presses,

New approach to closing the water system

Recycling and cleaning of save all clear filtrates

Minimizing the long loop water volume

Minimizing the salts at chemicals and process

0 m3/t

Available Metso Water Management Technologies

All fresh water to paper machine

Effluent treatment with FlooBed

and OptiDaf

Counter current principle for all process water