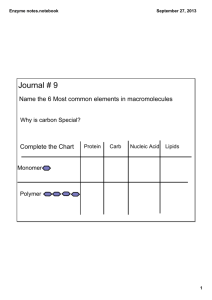

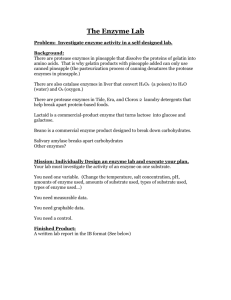

Analysis of factors influencing enzyme activity and stability in the

advertisement