15-47 Four-Variance Analysis of Total Overhead Variance (60

15-47 Four-Variance Analysis of Total Overhead Variance (60-75 minutes)

Variable factory overhead

Flexible Budget (FB) based FB Based on Output

on Inputs (i.e., hrs. worked) (i.e., allowed hours)

Actual (AQ × SP)

$352,000 440,000 × SP

(SQ

SQ

×

×

SP)

SP

Spending Variance Efficiency Variance

Fixed factory overhead

Actual

Budget Applied

(“Lump-Sum”)

200,000 units × $3/unit

(SQ × SP)

$575,000 = $600,000 396,000 × SP

Spending Variance Production Volume

Variance

1. a. Total units manufactured

Standard hours allowed per unit manufactured

Total standard hours for the units manufactured

198,000

× 2

396,000 b. Standard variable factory overhead rate per hour

Total budgeted factory overhead

Denominator activity (capacity level)

Fixed factory overhead rate per unit

Total budgeted fixed factory overhead

Total budgeted variable factory overhead

Total direct labor hours @ capacity (200,000 × 2)

Standard variable factory overhead rate per hour

∴ Variable factory overhead efficiency variance

200,000

× $ 3.00

= (440,000 − 396,000) DLHs × $0.75/DLH =

$900,000

$600,000

$300,000

÷ 400,000

$0.75

$33,000U

c. Variable factory overhead incurred (given)

FB based on Inputs = 440,000 DLHs × $0.75/DLH

Variable overhead spending variance d. Fixed factory overhead incurred (given)

Budgeted fixed factory overhead

Fixed factory overhead spending variance e. Total standard hours allowed for units manufactured

Standard fixed overhead rate/DLH = $3.00 ÷ 2

Total fixed factory overhead applied to production

Alternative computation:

Units manufactured (given)

Standard fixed factory overhead rate/unit (given)

Total fixed overhead applied f. Total budgeted fixed factory overhead

=

=

=

=

=

=

$352,000

330,000

$ 22,000U

$575,000

600,000

$ 25,000F

396,000

$1.50

$594,000

198,000

× $3.00

$594,000

$600,000

Total applied fixed factory overhead

Fixed factory overhead production volume variance

$594,000

$ 6,000U

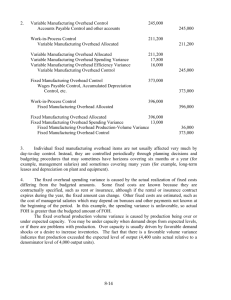

(2) Journal entries:

Dr. Variable Overhead

Cr. Accounts payable, etc.

352,000

To record actual variable overhead costs for the period.

Dr. WIP Inventory ($0.75 × 396,000)

Cr. Variable Overhead

297,000

297,000

To apply standard variable overhead costs to production for the period.

Dr. Variable Overhead Spending Variance

Dr. Variable Overhead Efficiency Variance

Cr. Variable Overhead

To record variable overhead variances for the period.

22,000

33,000

352,000

55,000

Dr. Fixed Factory Overhead

Cr. Accumulated depreciation, etc.

To record actual fixed overhead costs for the period.

575,000

575,000

Dr. WIP Inventory (396,000 × $1.50) 594,000

Cr. Fixed Factory Overhead 594,000

To apply standard fixed overhead costs to production for the period.

Dr. Production Volume Variance

Dr. Fixed Factory Overhead

Cr. Fixed Overhead Spending Variance

To record fixed overhead variances for the period.

6,000

19,000

25,000

(3) One view of the production volume variance is an artifact of the product-costing purpose of standard costing. To “unitize” budgeted fixed overhead for productcosting purposes, a “denominator activity level” must be chosen over which the budgeted fixed overhead costs can be spread. If the actual level of activity differs from the level chosen to establish the fixed overhead application rate, a production volume variance will occur. From a cost-control standpoint, the production volume variance, particularly when the denominator activity level is defined as “practical capacity,” can be thought of as representing the “cost of unused capacity.” As such, this variance information can be monitored over time to help better manage the supply of capacity-level resources.

The fixed overhead spending variance represents the difference between planned

(budgeted) fixed overhead costs and actual fixed overhead costs for the period. If management desires, this total variance can be broken down on a line-item basis.

The variable overhead spending variance is partly attributable to the fact that the measure(s) chosen to budget variable overhead costs are imperfect. In the present case, a single activity measure, DLHs, is used to construct the flexible budget for variable overhead cost. We know that such a simplification introduces error into the variance-determination process. This variance is also attributable to spending on overhead items being different from expectations. These variances (e.g., spending on electricity) can theoretically be decomposed into price and quantity components, much the same as we did in chapter 14 for direct manufacturing costs.

The variable overhead efficiency variance refers to the impact of manufacturing overhead of efficiency or inefficiency in the use of the activity measure(s) used to construct the flexible-budget for variable overhead. It is a misnomer, therefore, to interpret this variance as measuring the effect of efficiencies/inefficiencies associated with the consumption of individual variable overhead components. Note, too, that this variance is affected by the strength of the relationship between variable overhead cost and the activity measure(s) used to budget these costs for control purposes. That is, a “clean” interpretation of this variance exists only if the relationship between cost and activity is perfect.